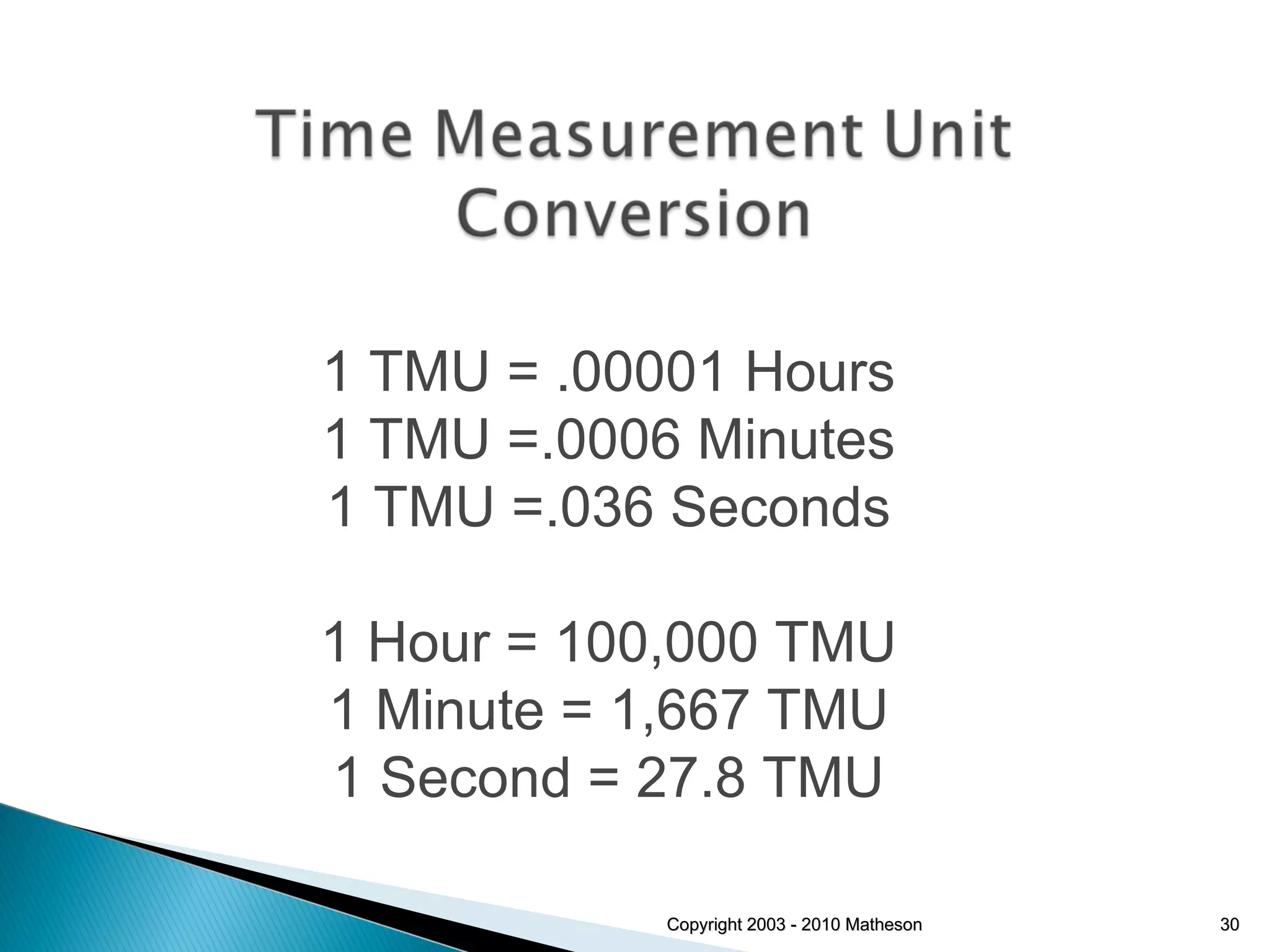

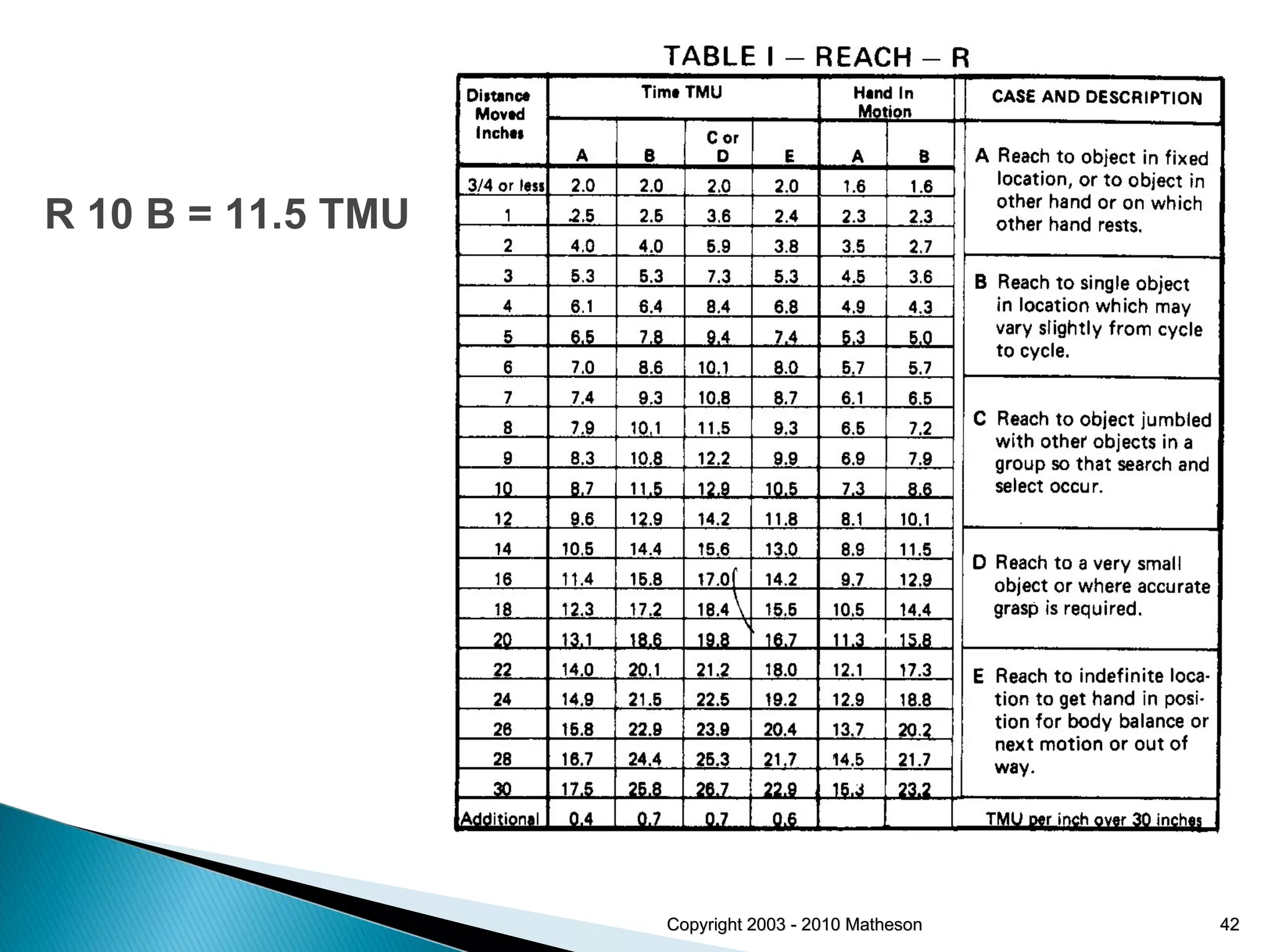

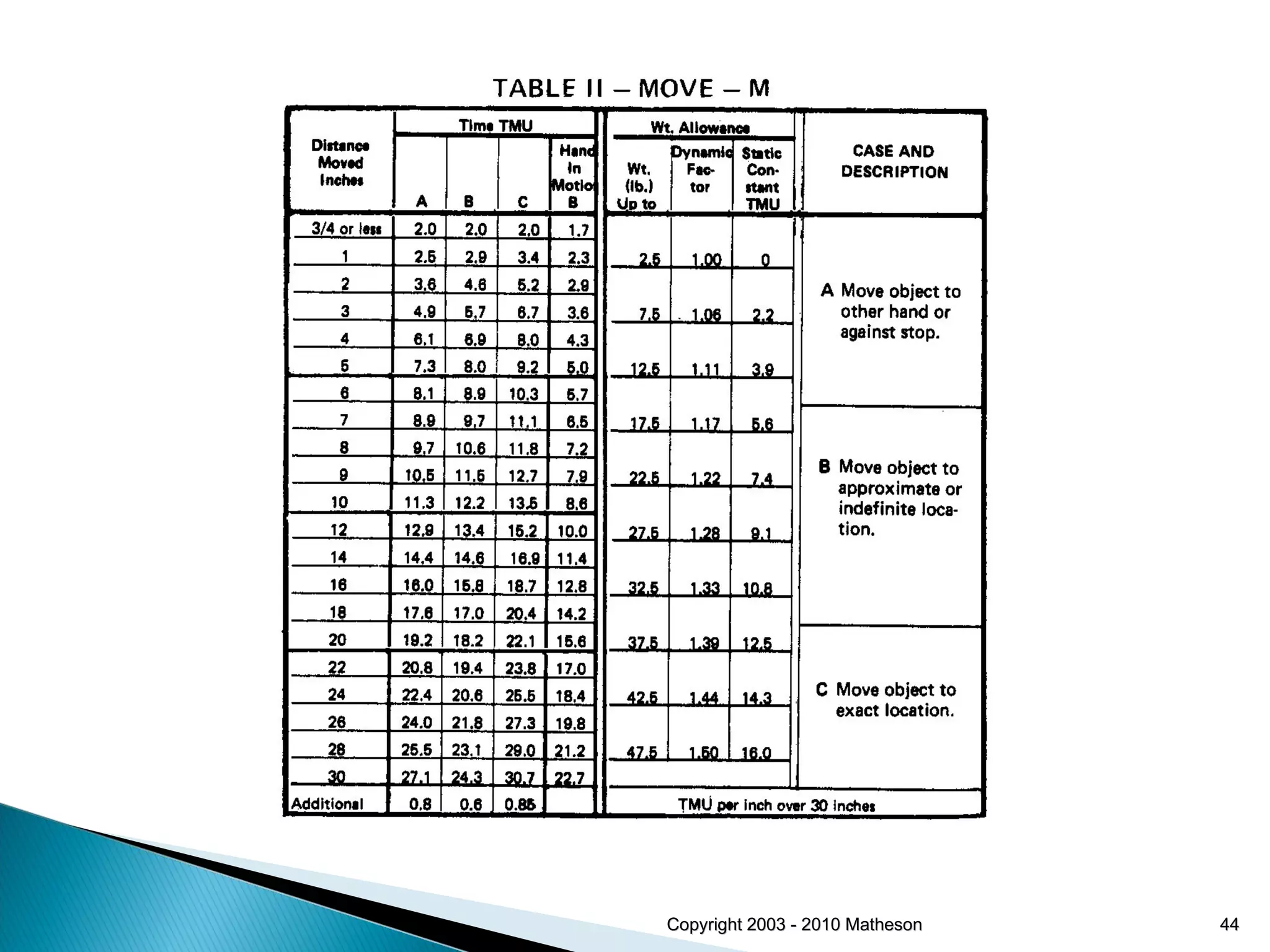

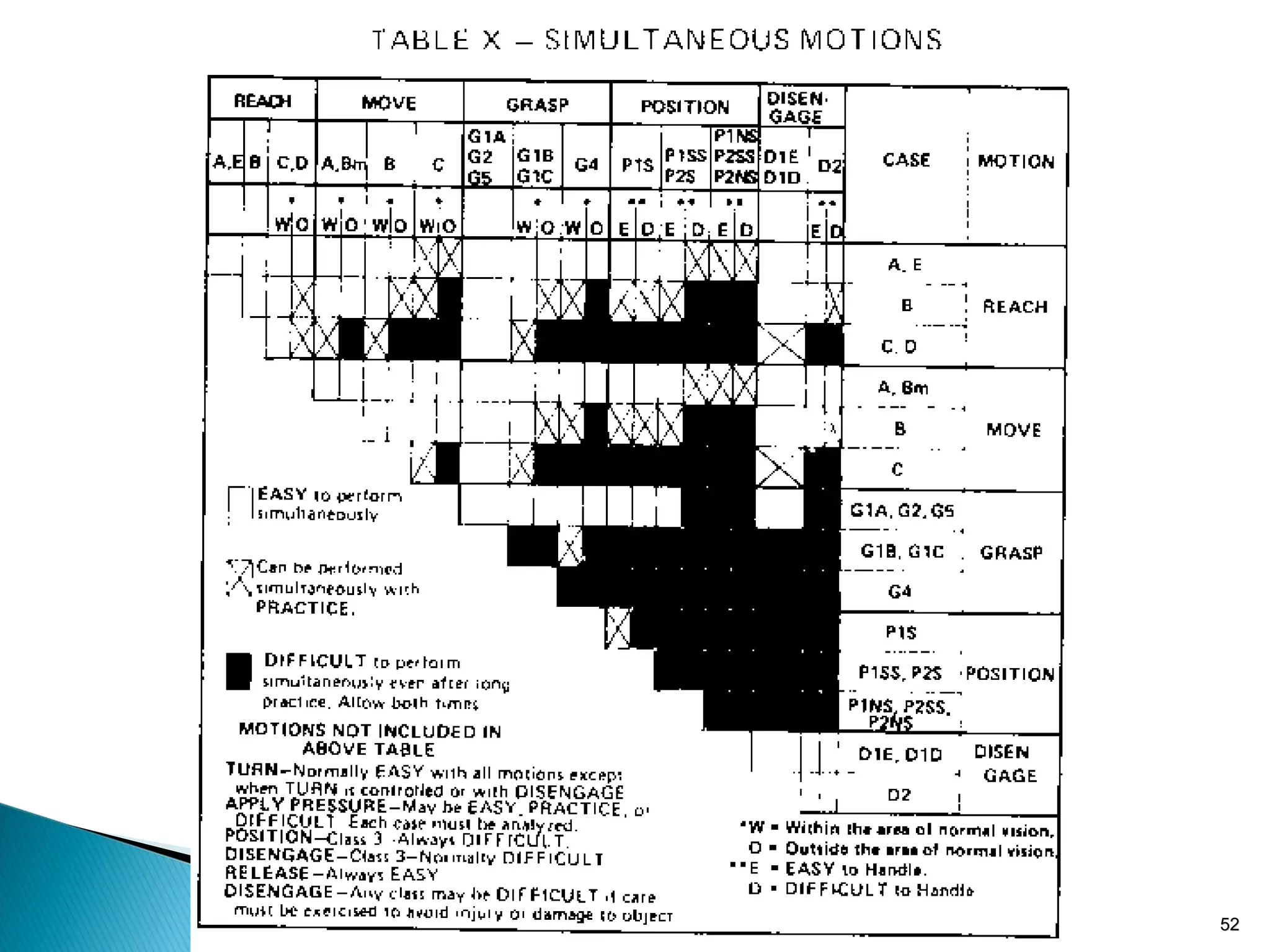

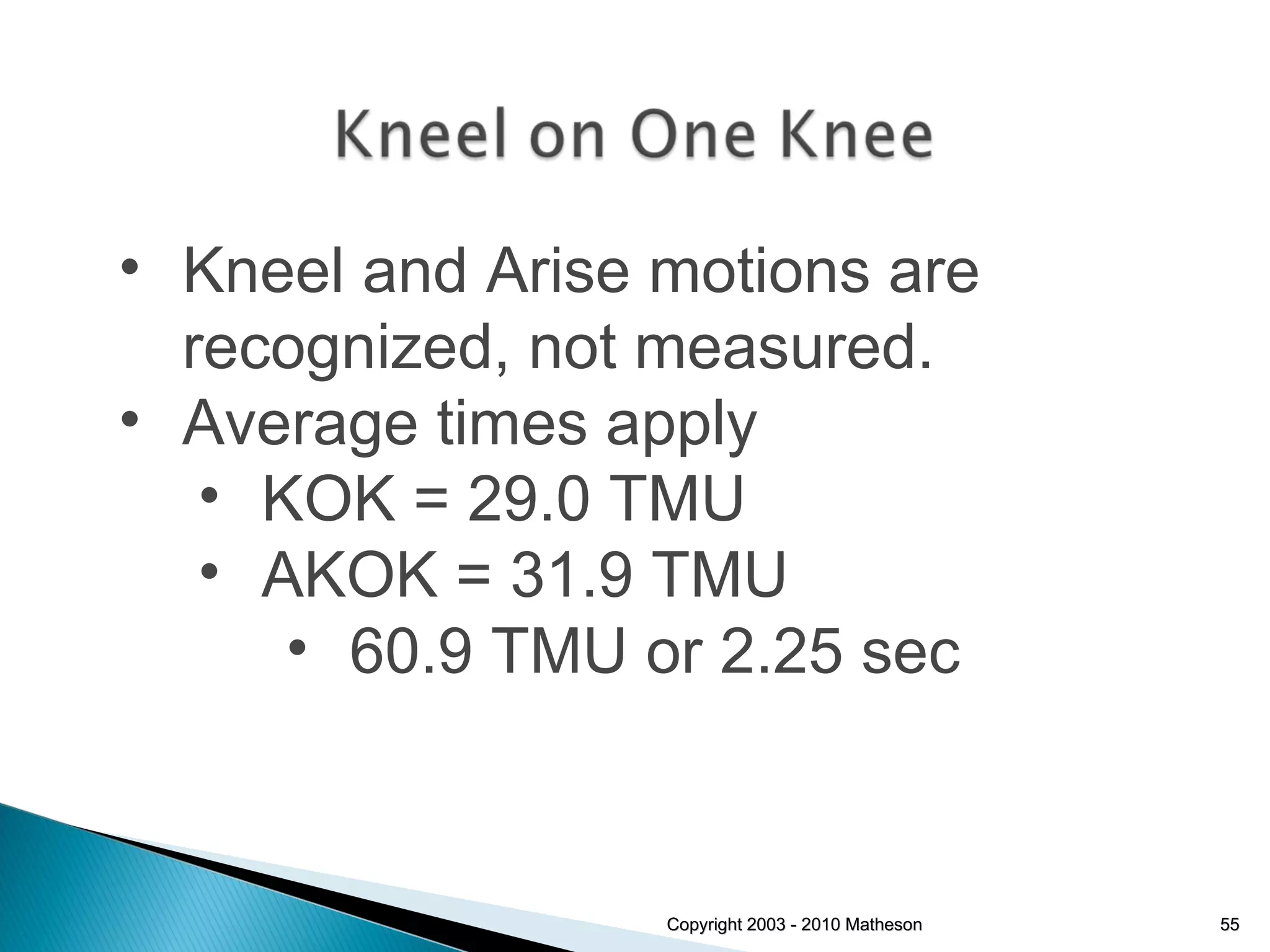

The document provides an overview of Method-Time Measurement (MTM), detailing its definitions, analysis procedures, and applications in evaluating manual operations through standardized time measurements. It emphasizes the importance of predetermined time units and the relationship between MTM and Functional Capacity Evaluations (FCE). Additionally, it covers fundamental motions assessed by MTM, along with its historical context and relevance in work measurement standards.