This document outlines the process validation plan for a solid dosage anti-tuberculosis drug. It begins with an introduction and outline. It then discusses the stages of process validation, literature review, and plan of work. The document describes the manufacturing process and identifies critical and non-critical process parameters. It discusses sampling plans, statistical tools for analysis, and key references. The overall aim is to assure consistent quality and reduce defects through process validation.

![Validation conducted

prior to the

distribution of either

a new product or a

product made under a

revised

manufacturing

process

A process where

current production

batches are used to

monitor processing

parameter

Retrospective

validation is the

validation of a process

based on accumulated

historical data

PROSPECTIVE

VALIDATION

CONCURRENT

VALIDATION

RETROSPECTIVE

VALIDATION

TYPES OF PROCESS VALIDATION (1984 USFDA) [4]

7](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-7-2048.jpg)

![8

Continuous

process

verification

Continuous

Process

Verification

[1]](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-8-2048.jpg)

![INTENT TYPICAL ACTIVITIES

To define the commercial process

on knowledge gained through

development and scale up

activities .

The outcome is the design of a

process suitable for routine

manufacture that will consistently

deliver product that meets its

critical quality attributes

A combination of product and

process design (quality by design)

Product development activities

Experiment to determine process

parameters, variability, and

necessary controls

Risk assessments

Other activities required to define

the commercial process

Design of experiment testing

STAGE 1: PROCESS DESIGN [1]

9](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-9-2048.jpg)

![ To confirm the process design as

capable of reproducibility

Commercial manufacturing

Facilities design

Equipment and utilities

qualification

Performance qualification (PQ)

Strong emphasis on the use of

statistical analysis of process data

to understand process consistency

and performance.

INTENT TYPICAL ACTIVITIES

STAGE 2 : PROCESS QUALIFICATION [1]

10](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-10-2048.jpg)

![Installation

Qualification

Establish by objective evidence that all key

aspect of the process equipment and ancillary

system are adhere to manufacturing

specification

Operational

Qualification

Establish by objective evidence process control

limit and the action levels which result in

product that all predetermine requirement

Performance

Qualification

Establish by objective evidence that the process

,under anticipated conditions, consistently

produces product which meets all predetermine

requirement

STAGE 2: PROCESS QUALIFICATION [4]

11](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-11-2048.jpg)

![ To provide ongoing assurance that

the process remains in the state of

control during routine production

through procedure

Continuous improvement

initiatives

Proceduralised data collection

from every batch

Data trending and statistical

analysis

Product review

Equipment and facilities

maintenance

Calibration

Improvement initiatives through

process experience

INTENT TYPICAL ACTIVITIES

STAGE 3:CONTINUED PROCESS VERIFICATION [1]

12](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-12-2048.jpg)

![STAGE 1

PROCESS DESIGN

STAGE 2

PROCESS QUALIFICATION

(PQ)

DESIGN OF

FACILITIES &

QUALIFICATION

OF EQUIPMENT

AND UTILITIES

PROCESS

PERFORMANCE

QUALIFICATION

(PQR)

EVALUATE/ CONFIRM

STAGE 3

CONTINUED PROCESS VERIFICATION

(CPV)DISTRIBUTE

Three model of process validation according to FDA guidance for

industry [5]

distribute

13](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-13-2048.jpg)

![15

PARAMETER DESCRIPTION

IUPAC NAME

(7S,9E,11S,12R,13S,14R,15R,16R,17S,18S,19E,21Z)-

2,15,17,27,29-pentahydroxy-11-methoxy-3,7,12,14,16,18,22-

heptamethyl-26-[(1E)-[(4-methylpiperazin-1-yl)imino]methyl]-

6,23-dioxo-8,30-dioxa-24-

azatetracyclo[23.3.1.1⁴,⁷.0⁵,²⁸]triaconta-1(29),2,4,9,19,21,25,27-

octaen-13-yl acetate

MOLECULAR WEIGHT 822.9402

MOLECULAR FORMULA C43H58N4O12

MECHANISM OF ACTION

Rifampin acts via the inhibition of DNA-dependent RNA

polymerase, leading to a suppression of RNA synthesis and cell

death.

RIFAMPICIN :-](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-15-2048.jpg)

![17

PARAMETER DESCRIPTION

IUPAC NAME

(2S)-2-[(2-{[(2S)-1-hydroxybutan-2-

yl]amino}ethyl)amino]butan-1-ol

MOLECULAR WEIGHT 204.3098

MOLECULAR FORMULA C10H24N2O2

MECHANISM OF ACTION

Ethambutol inhibits arabinosyl transferases which is involved

in cell wall biosynthesis. By inhibiting this enzyme, the

bacterial cell wall complex production is inhibited. This leads

to an increase in cell wall permeability.

ETHAMBUTOL :-](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-17-2048.jpg)

![VALIDATION PROTOCOL [5]

Process validation protocols should include the following elements:

• Requirements for calibration of all measuring devices.

24

• Objectives, scope of coverage of the validation study.

• A list of all equipment to be used; their normal and worst case operating

parameters.](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-24-2048.jpg)

![Raw material dispensing

Sifting

Dry mixing

Binder preparation

Wet granulation

Drying

Sizing

Blend uniformity

% LOD

GENERAL MANUFAGTURING PROCESS OF TABLET [6,7,8]

26](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-26-2048.jpg)

![Manufacturing

Process Stage

Process Parameter

Critical/

Non-

critical

Justification

Sifting Sieve used for sifting (mesh size)

Non-

critical

Sifting has been

incorporate to break the

lump to remove foreign

particle if any.

Dry mixing

1. Dry mixing time

2. Impeller speed

Critical

It may have impact on

uniform distribution of

active material and

excipient

Wet granulation

Binder

addition

1. Add time

2. Impeller speed

Critical

Have impact on

homogeneity of

granulation process,

dissolution and physical

properties of granules

such as particle size

distribution and

followability

Kneading

1. Mix time

2. Impeller speed

3. Chopper sped

CRITICALAND NON-CRITICAL PARAMETER [6]

28](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-28-2048.jpg)

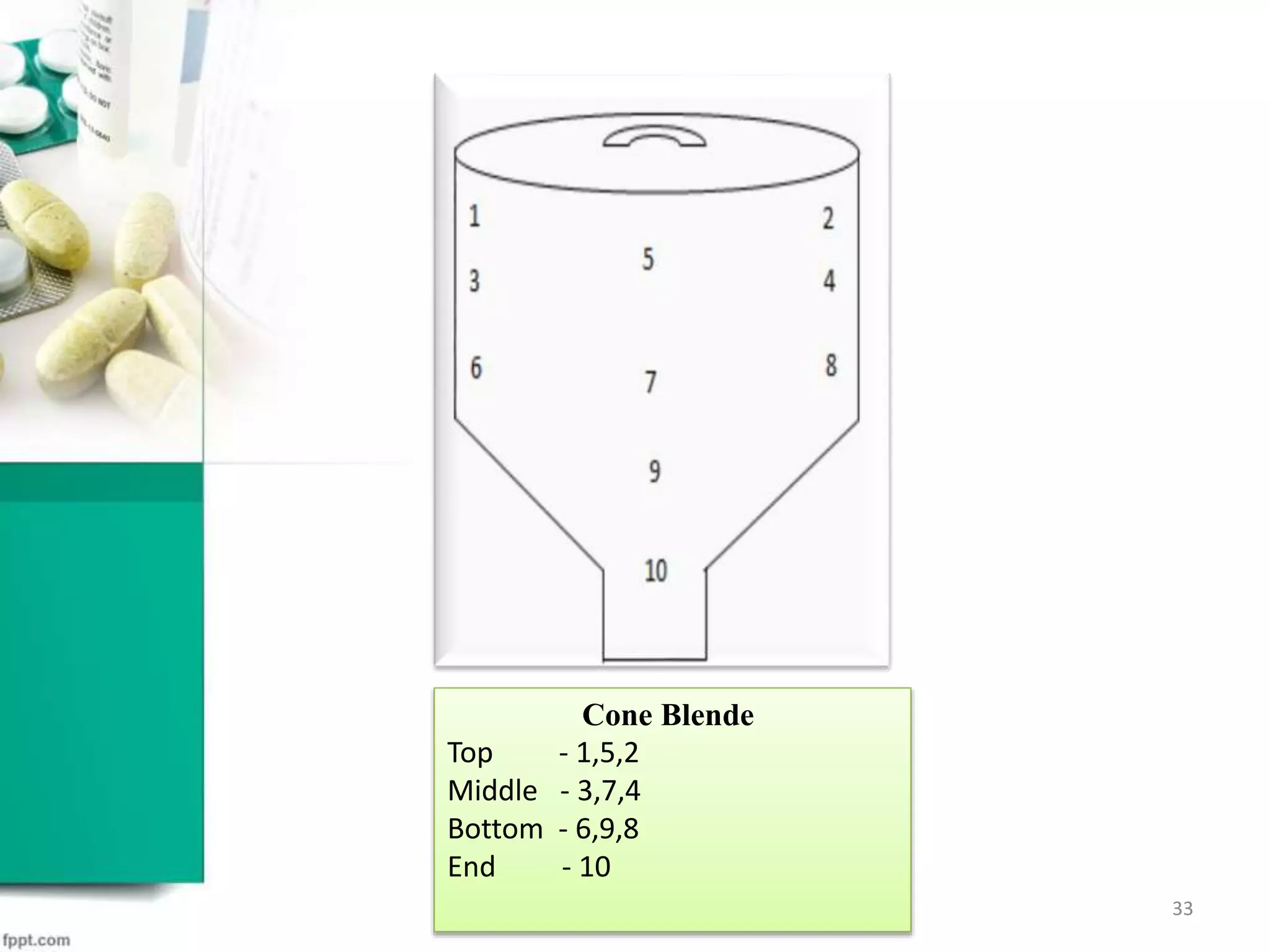

![• A detailed plan of sampling procedure of samples which shall be

analyzed/monitored during validation run shall be outline systematically

• The sampling plan including sampling points number of sample and the

frequency of sampling for each stage operation shall be decided based on

characteristic of the product or critical point of equipment

• Sampling location are to clearly indicate by diagram for any equipment from

which the sample are withdraw.

SAMPLING [7,8,10]

31](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-31-2048.jpg)

![Rapid Mix Granulator

T- top M- middle B-bottom

FBD Bowl

Four corner 1,2,3,4

SAMPLING TECHNIQUE [7,8]

32](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-32-2048.jpg)

![Stage Sampling Location Test To Be Performed

Dry mixing

3 point from top,3 point from

middle, 3 point from bottom of

bed from RMG

Blend uniformity

Drying Four corner of FBD and middle % LOD

Lubrication and

Blending

3 samples from top, middle,

bottom

Assay for BU, tapped density

Bulk density, angle of repose

Compression

Draw tablets from initial middle ,

and near end stage of compression

Description, assay, hardness,

thickness, diameter,

friability, weight variation,

CU, disintegration,

dissolution

Coating

Draw a tablets from coating pan at

the end of each lot

Same as above and related

substance test

SAMPLING AND ANALYSIS [6,7]

34](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-34-2048.jpg)

![STATISTICS IN VALIDATION [8,9]

“When you can measure what you are speaking about, and express

it in numbers, then you know something about it.”[8]

Statistical process control (SPC), also called statistical quality

control and process validation (PV), represents two sides of the

same coin. [8] 35](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-35-2048.jpg)

![ The collection and evaluation of information and data about performance of

the process will allow detection of undesired process variability

Evaluating the performance of the process identifies problem and

determine weather action must be taken to correct anticipate and prevent

problem so that the process remain in control

PROCESS VARIABILITY [9]

36](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-36-2048.jpg)

![STATISTICAL TOOL IN VALIDATION

Process Capability [9,10]

37](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-37-2048.jpg)

![ Control charts are used to detect changes in the process.

Control charts help to identify key input variables causing the process to shift

and aid in the reduction of the variation. Control charts are also used as part of

a capability study to demonstrate that the process is stable or consistent.

Control Chart [9,10]

39](https://image.slidesharecdn.com/fkjdshksdglfxk-161215091010/75/process-validation-39-2048.jpg)