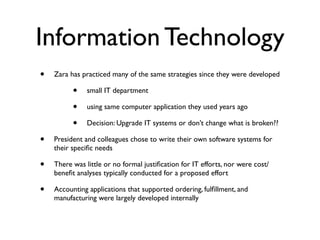

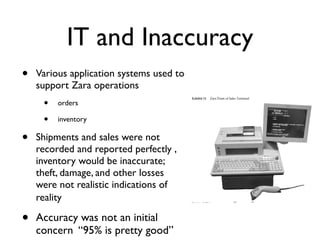

Zara has achieved success through a vertically integrated supply chain model that allows for rapid production and distribution, getting new designs from concept to stores in as little as three weeks. However, Zara's reliance on outdated information technology systems, including a DOS-based point-of-sale system and lack of internal communication capabilities, presents weaknesses that could threaten its competitive edge if not modernized. Upgrading its IT infrastructure would enable Zara to improve inventory accuracy, facilitate real-time communication across its global operations, and help it continue responding quickly to fashion trends.