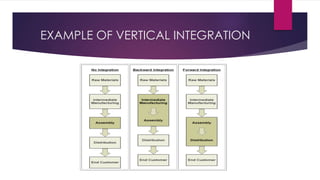

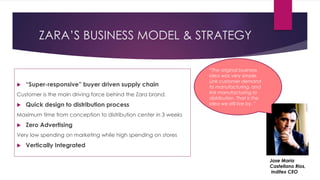

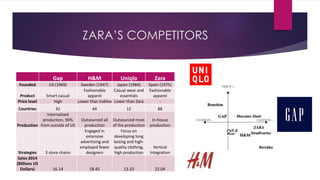

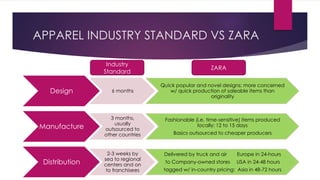

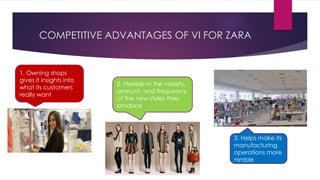

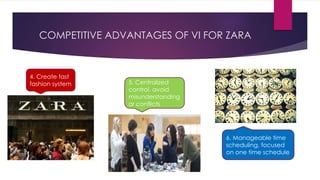

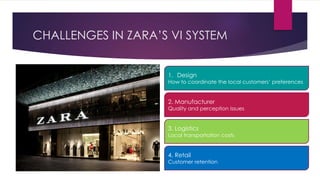

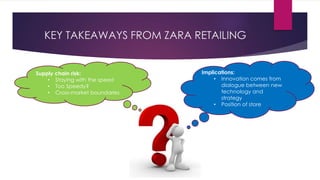

The document discusses vertical integration in the context of Zara, a leading fast-fashion retailer that maintains control over multiple production and distribution steps to enhance market power. It outlines Zara's unique business model which enables rapid design and distribution, high responsiveness to fashion trends, and a competitive edge despite a lack of traditional advertising. Key points about Zara's operations highlight its internalized production strategies, customer-centric approach, and challenges related to logistics and brand perception.