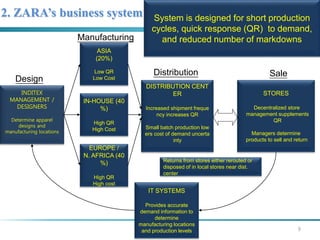

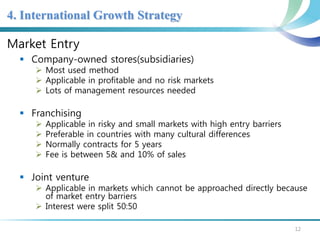

ZARA is a Spanish clothing brand owned by Inditex that pioneered fast fashion. ZARA's business model emphasizes vertical integration, producing clothing in small batches close to stores to facilitate quick response to trends. Stores provide frequent feedback to help designers continuously adapt products. About half of materials and 40% of products are manufactured internally. Distribution centers use advanced tracking to deliver to stores within 1-2 days in Europe and 2-4 days outside Europe. ZARA's approach reduces risks from unsold inventory compared to competitors. Its international growth follows an "oil stain" pattern entering culturally similar markets with company-owned stores.