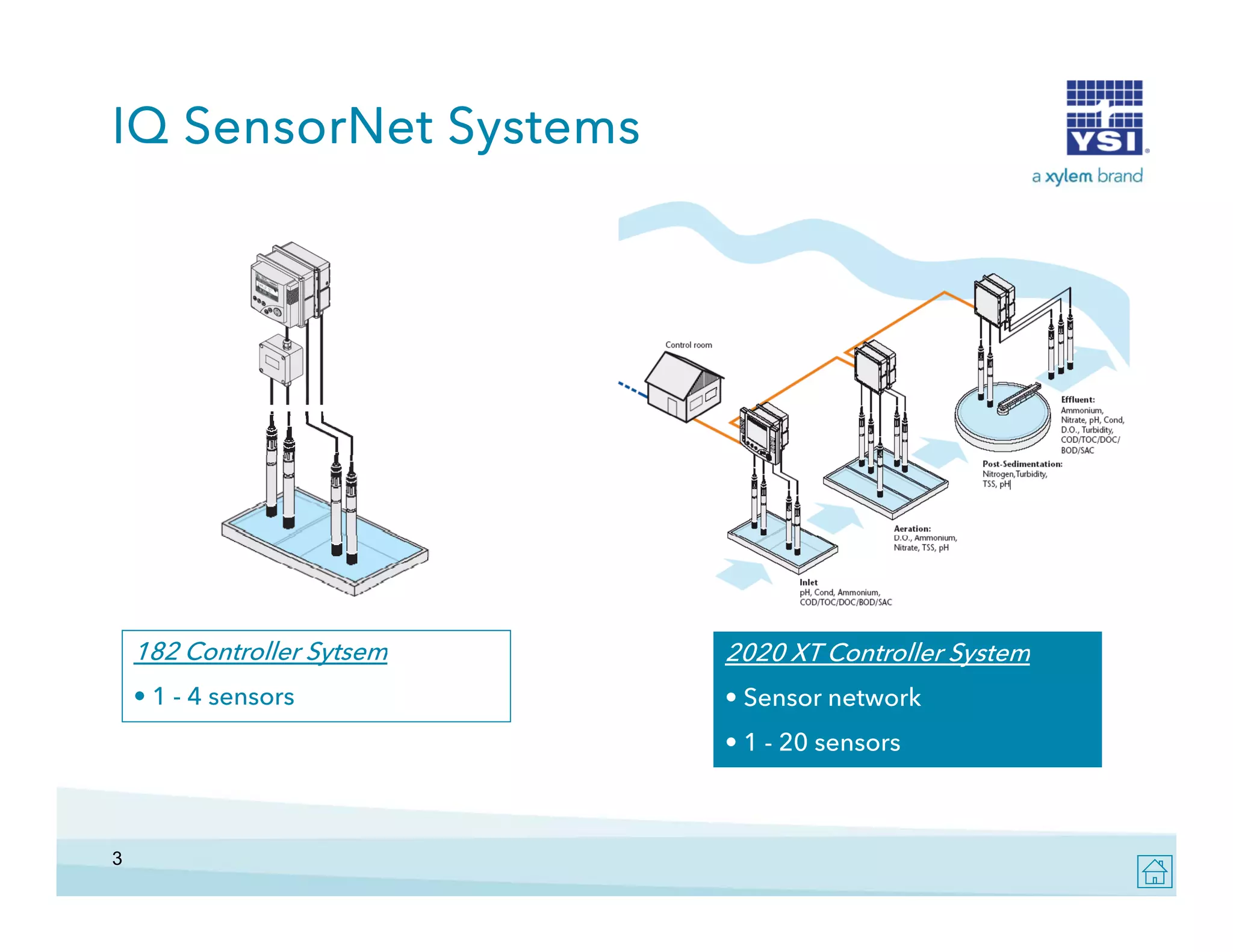

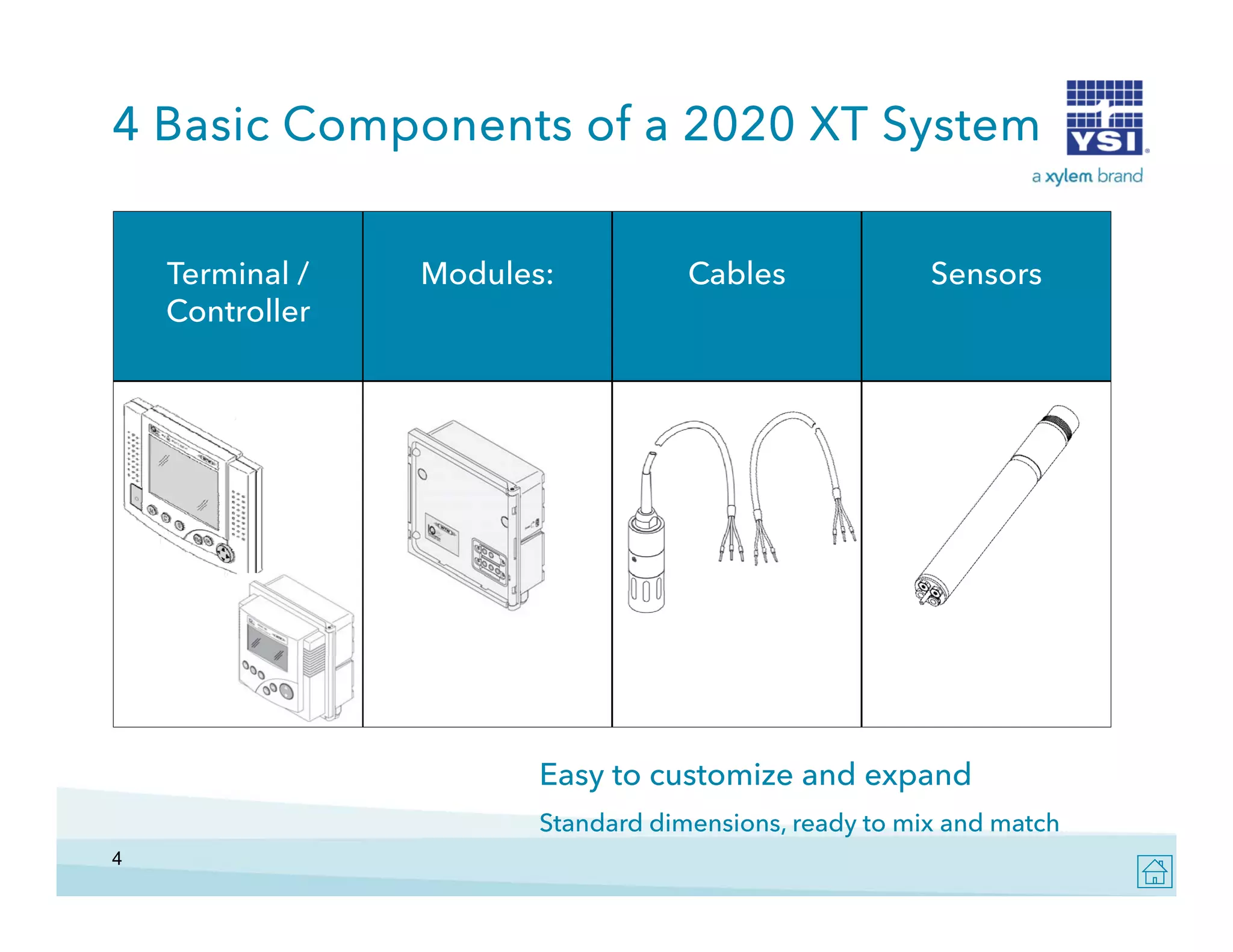

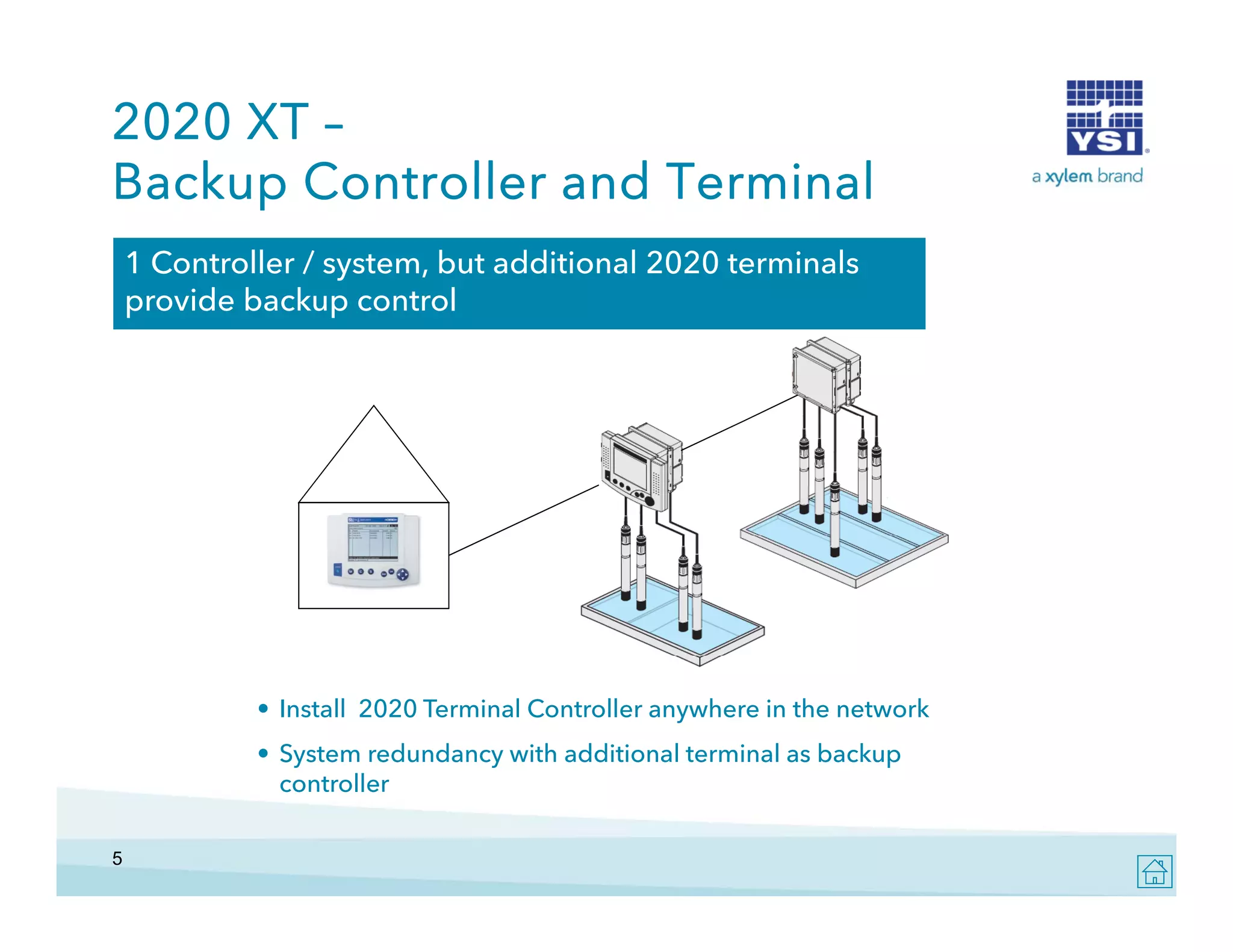

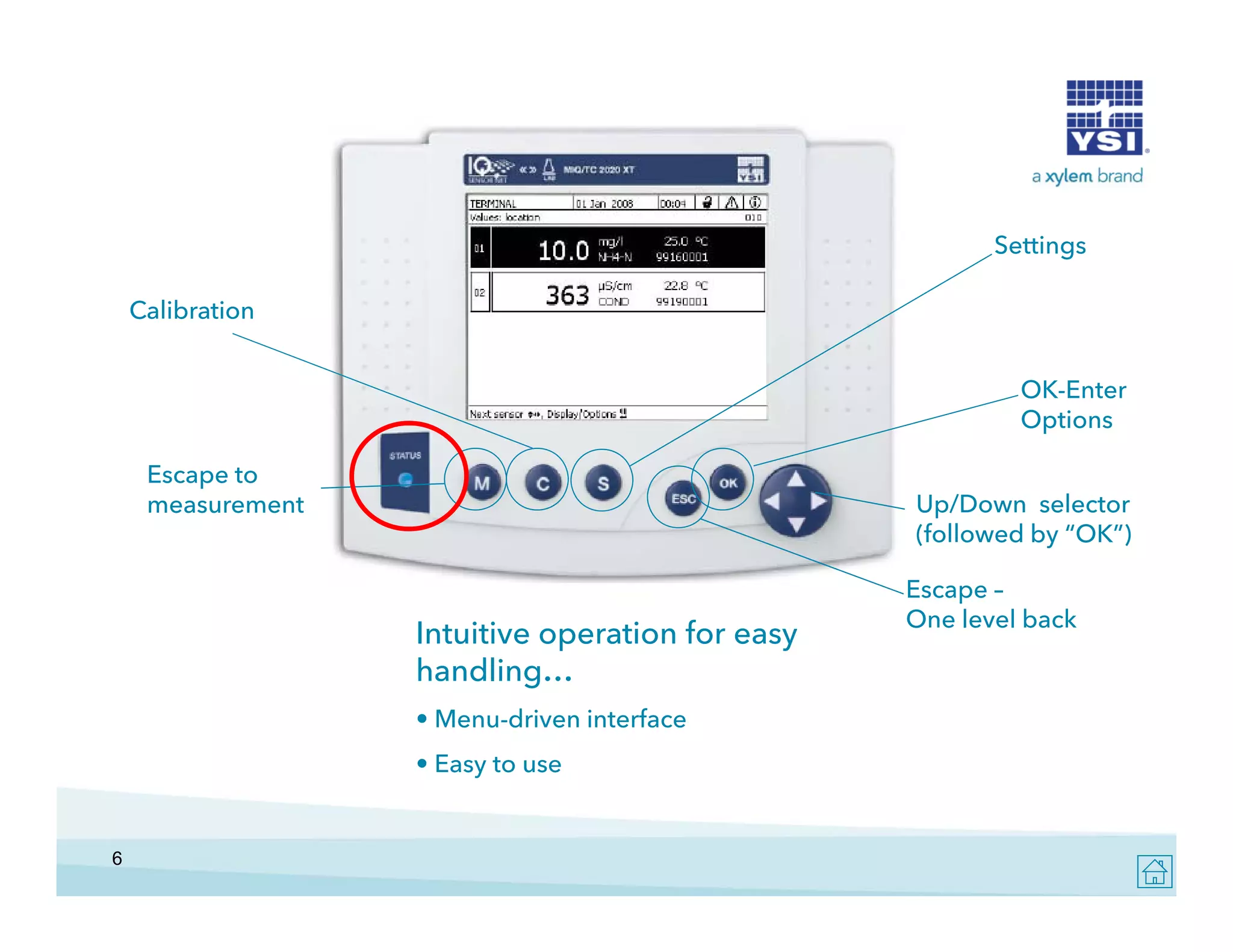

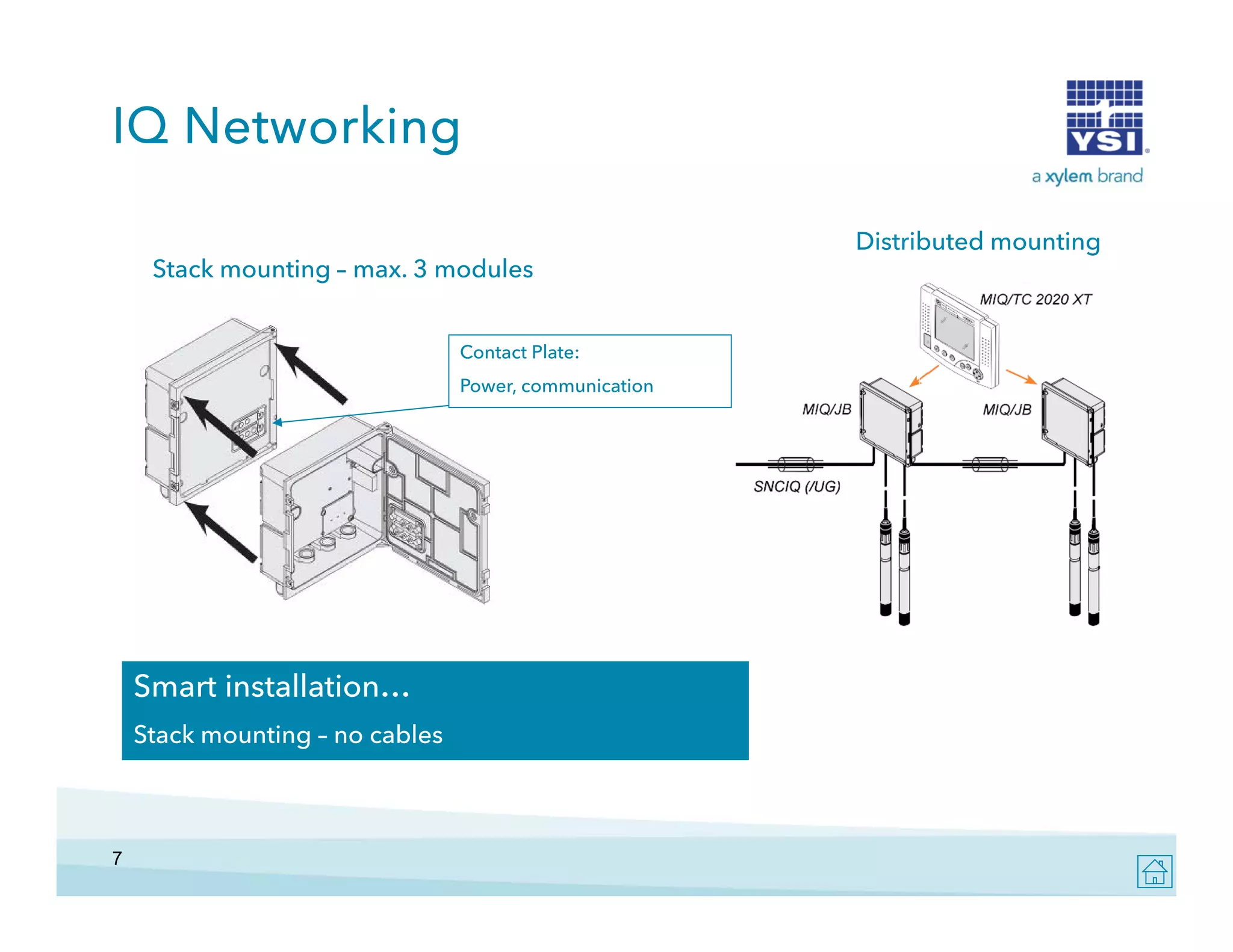

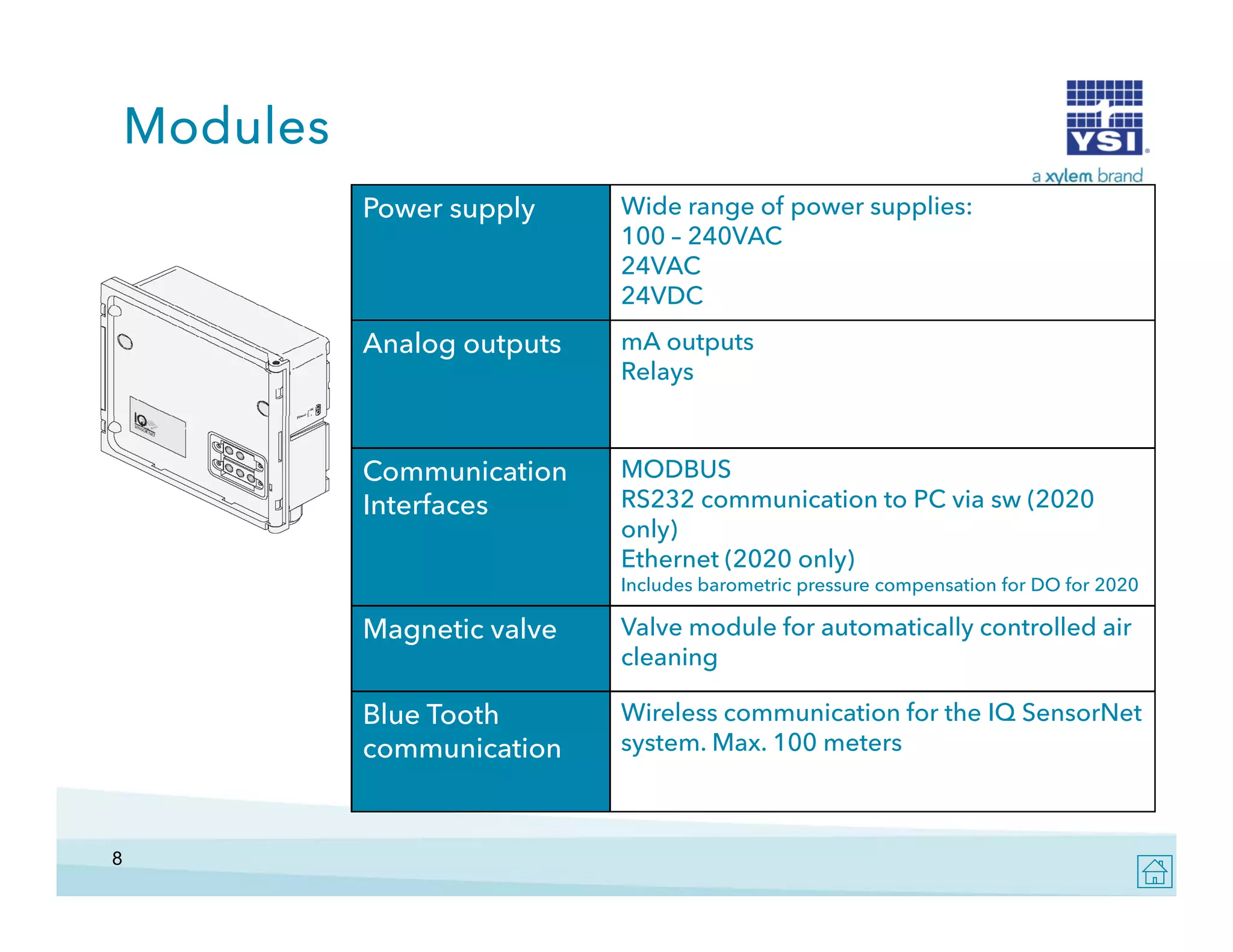

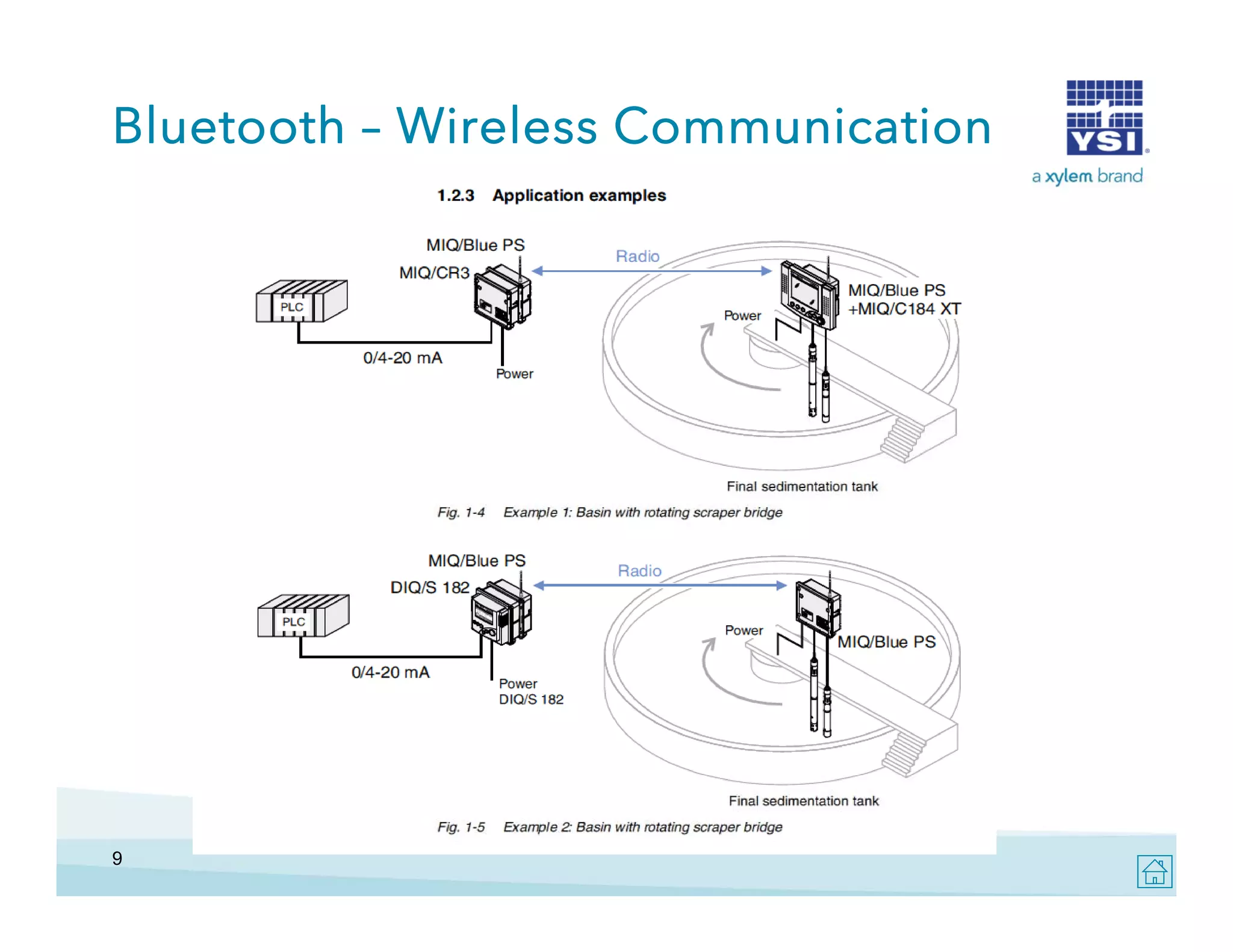

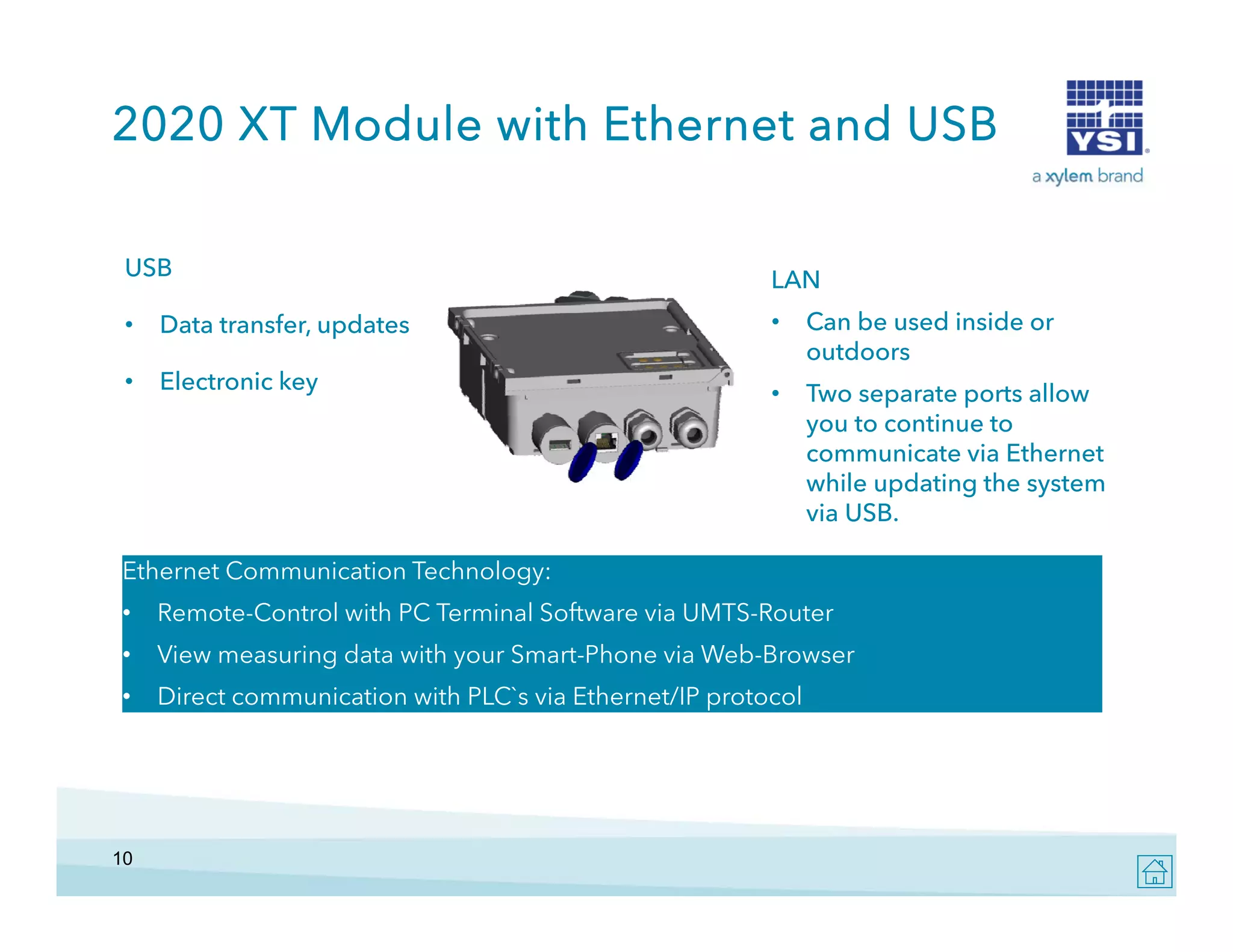

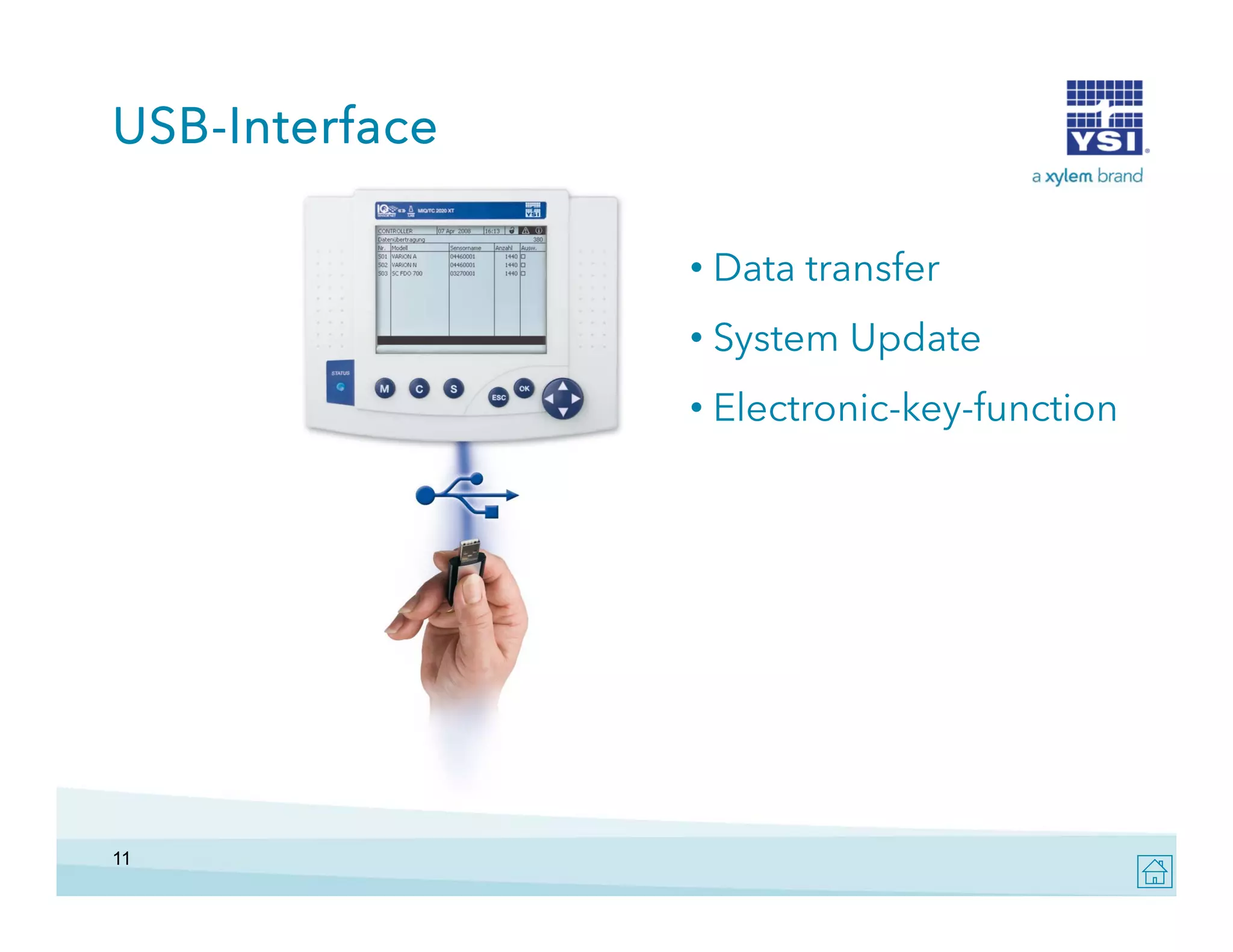

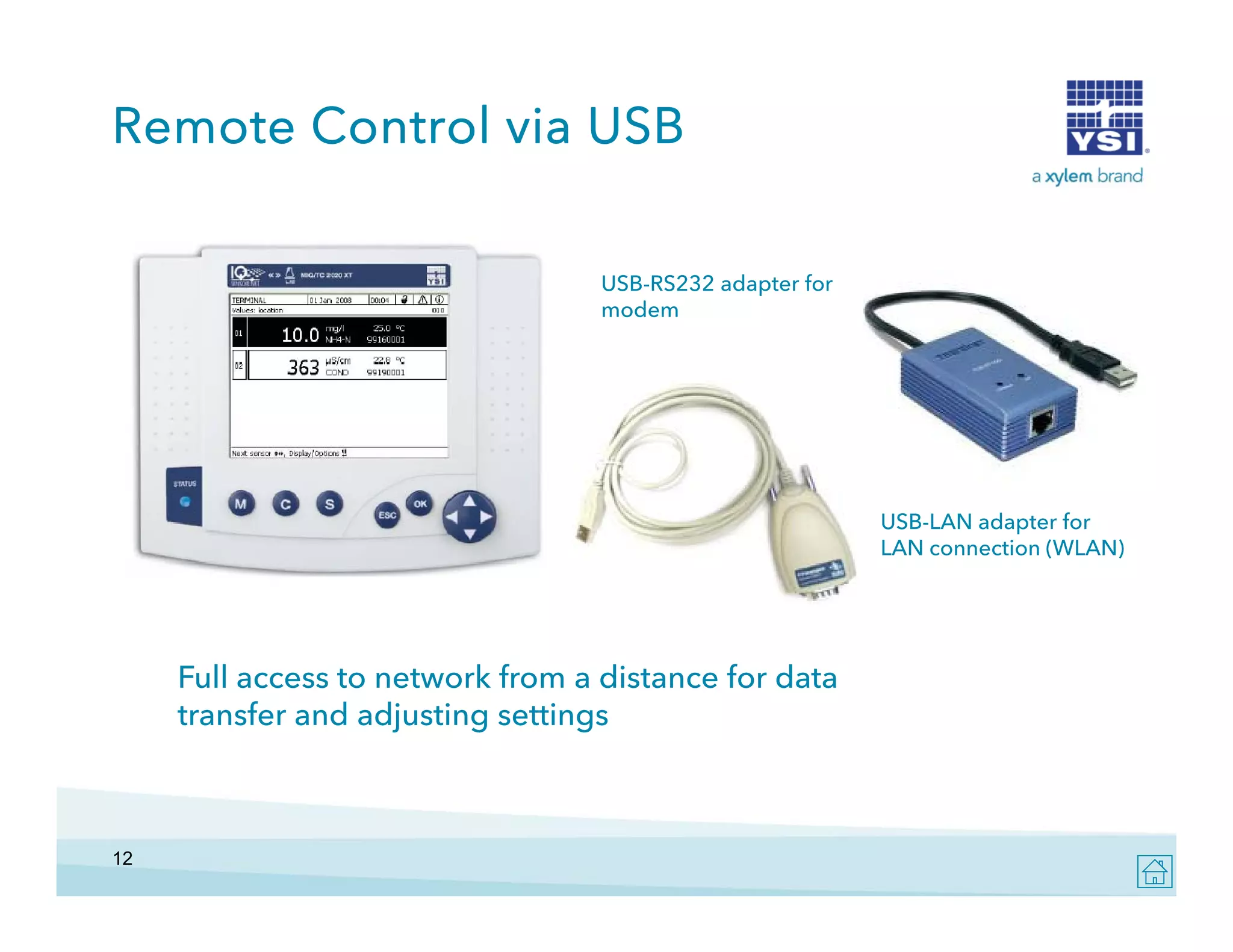

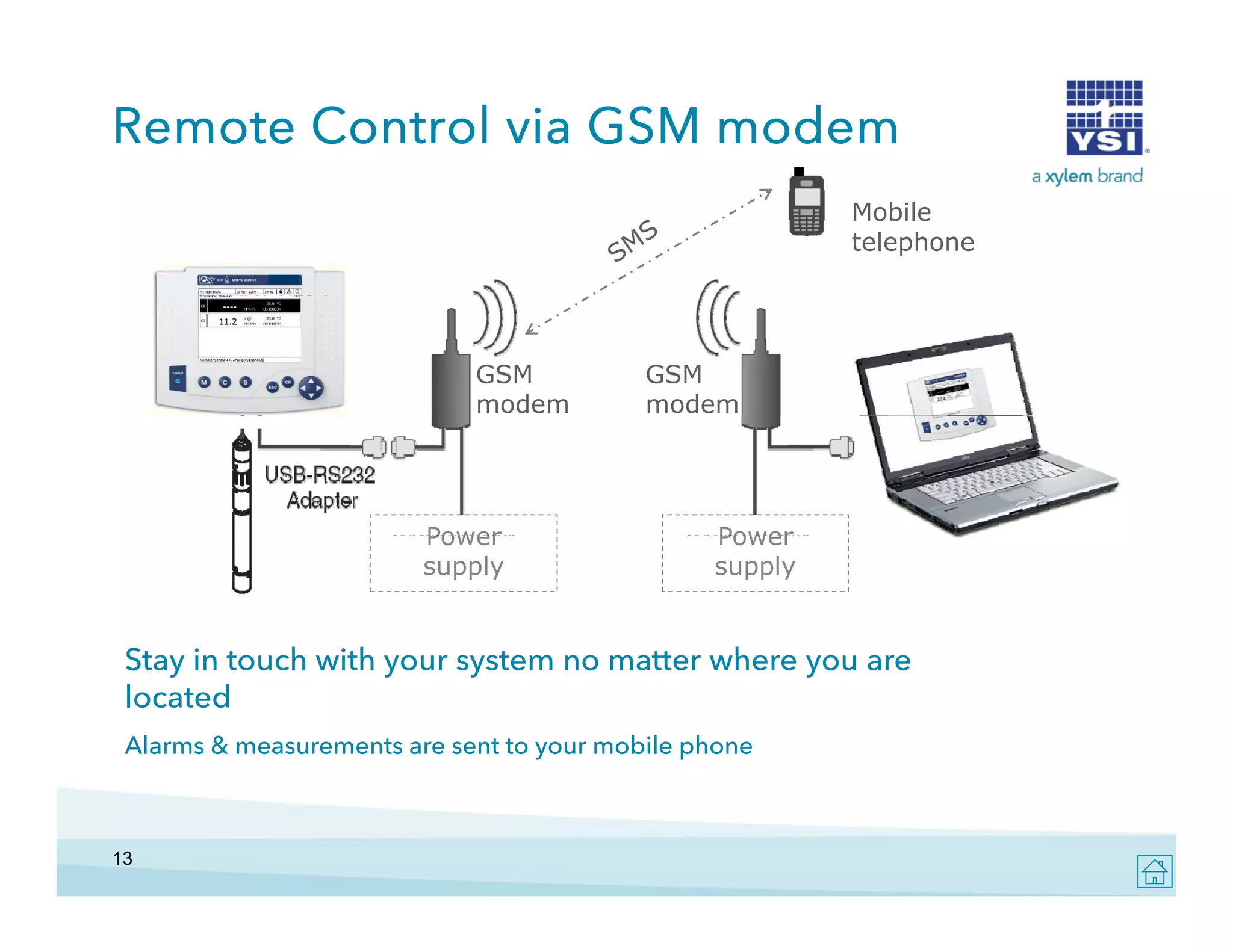

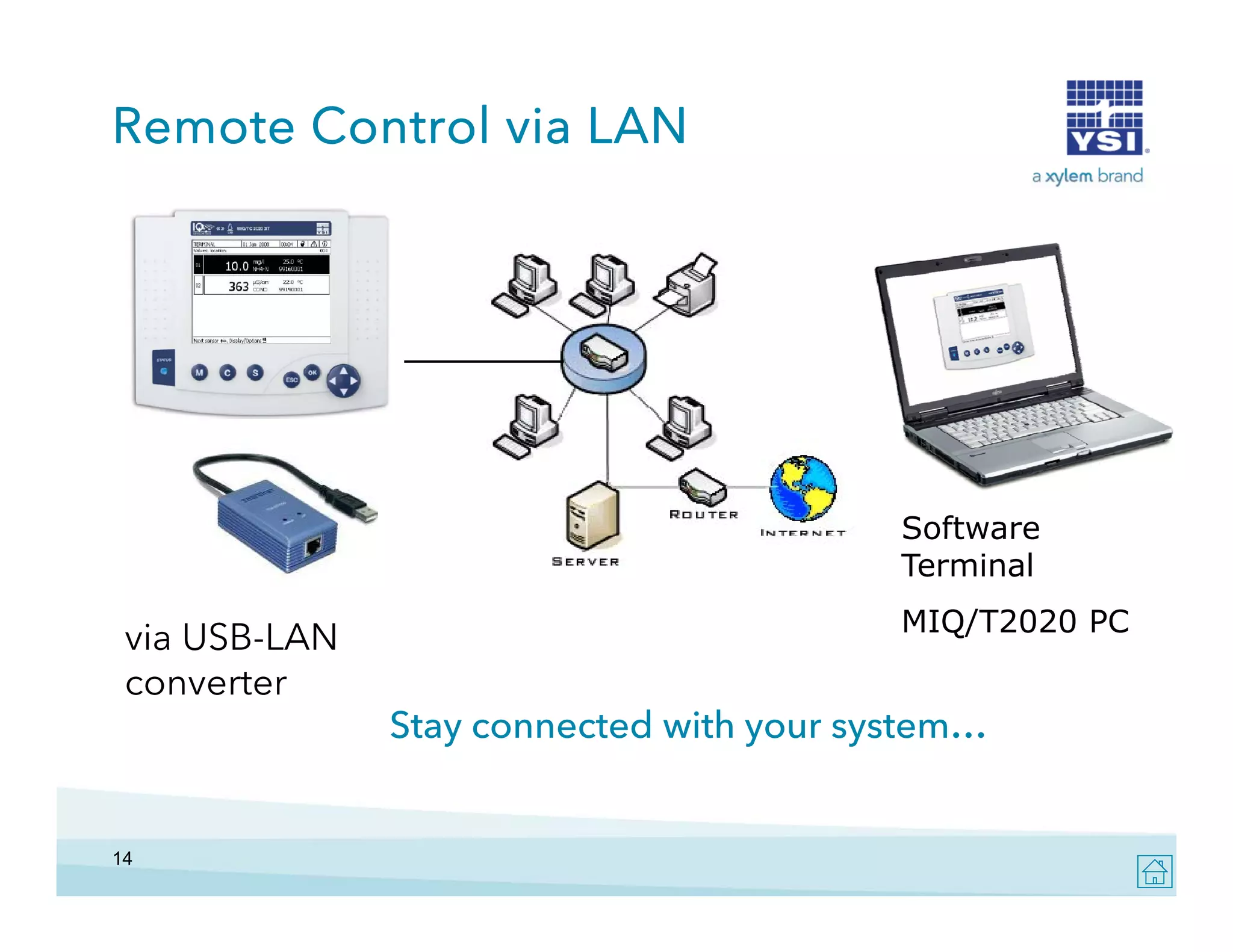

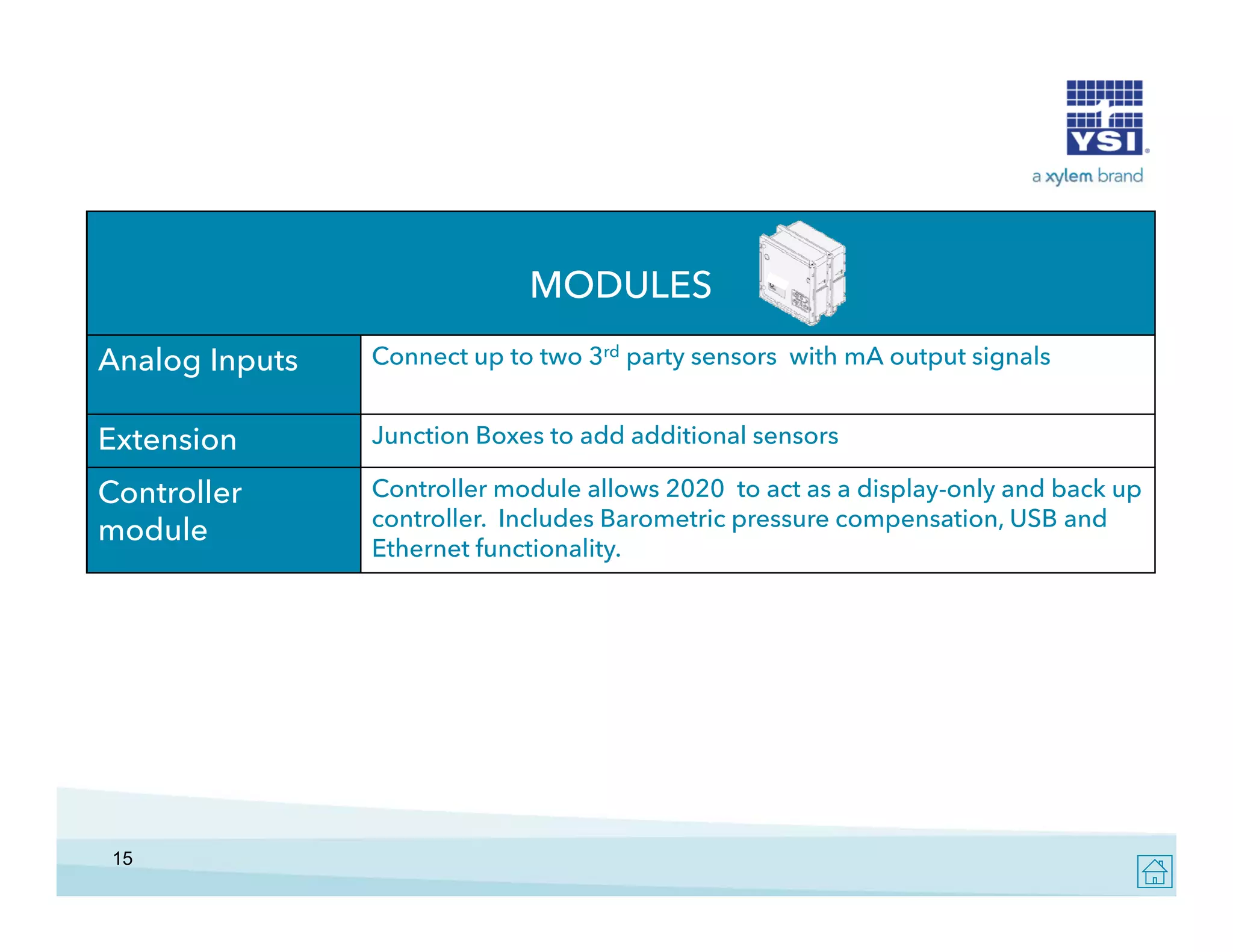

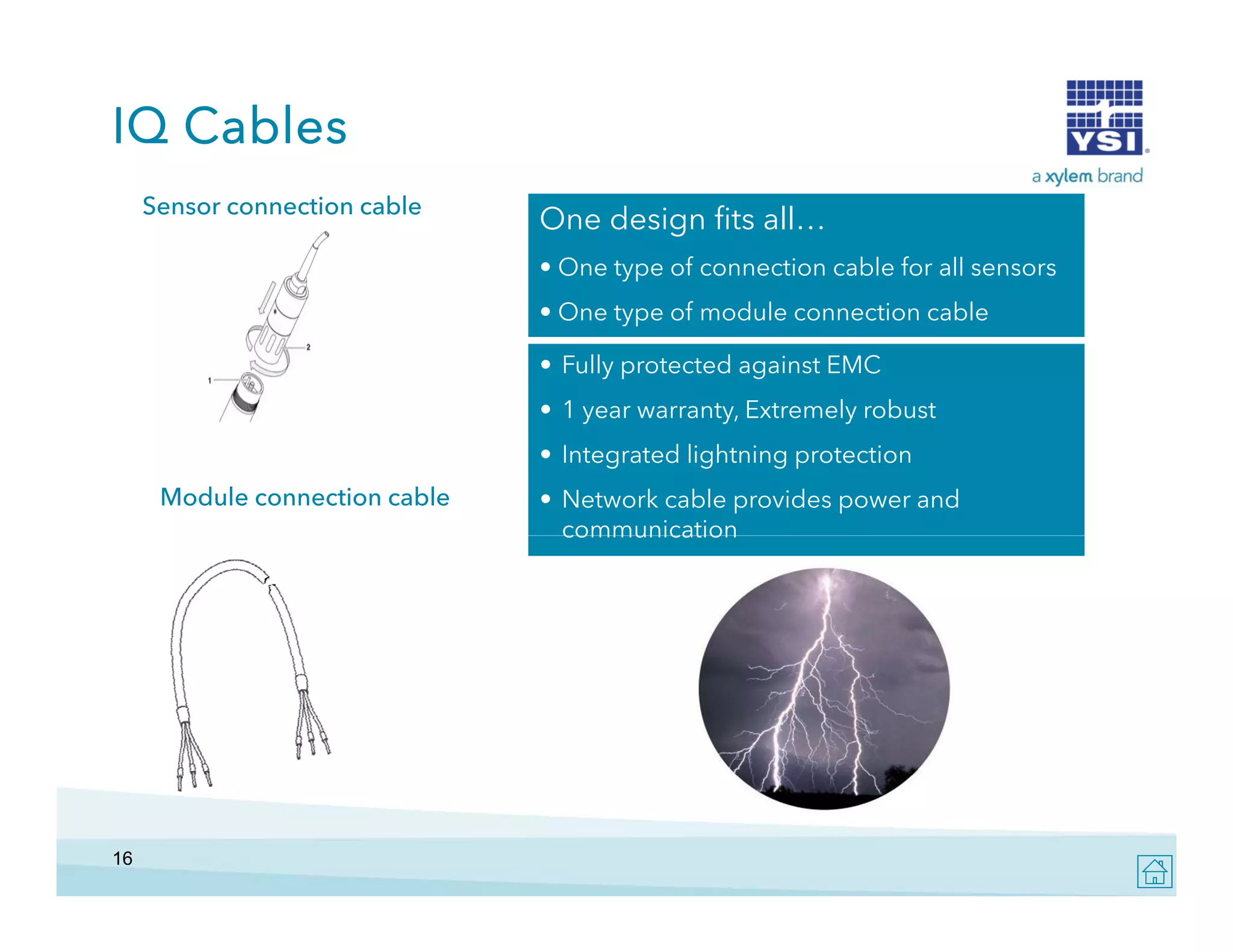

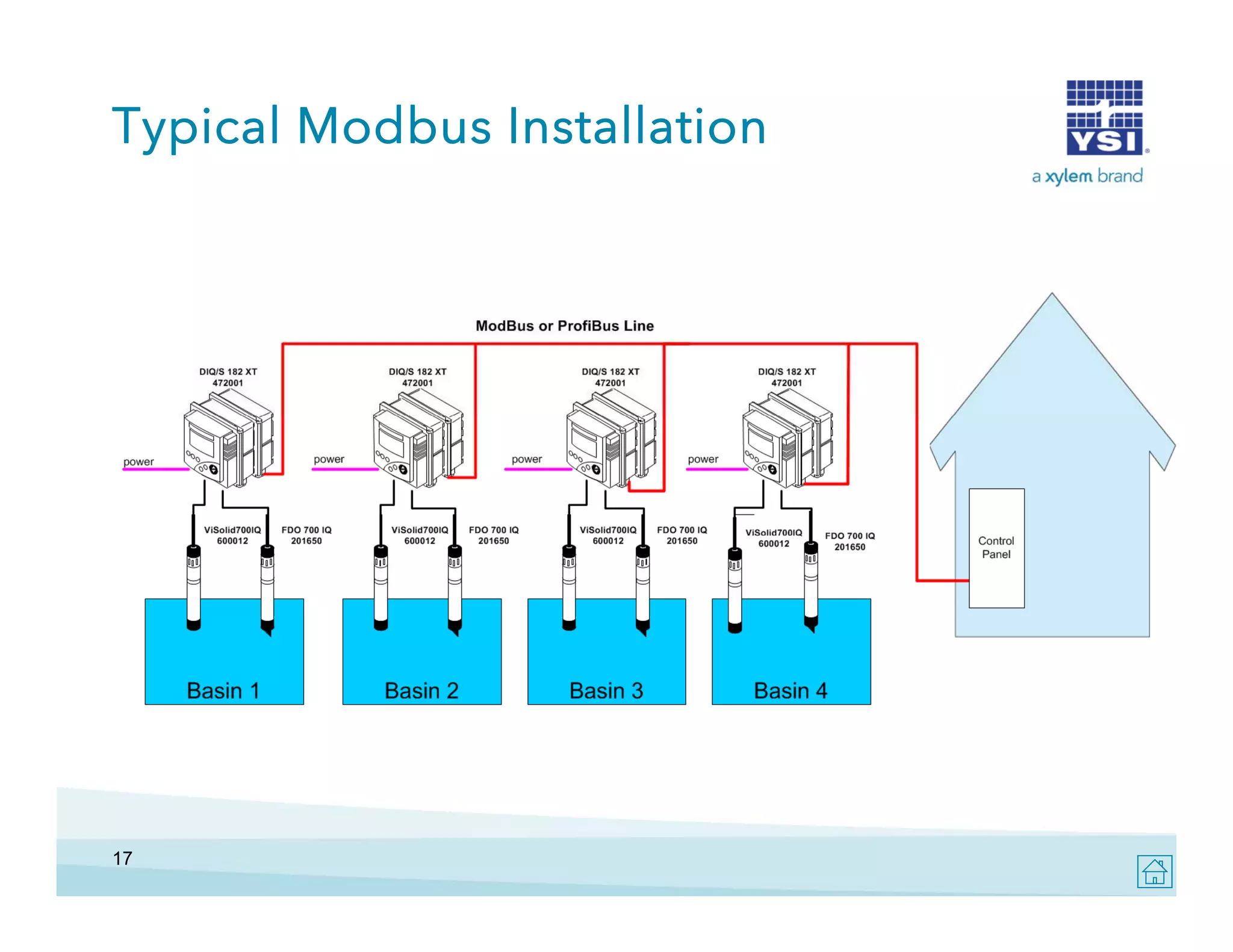

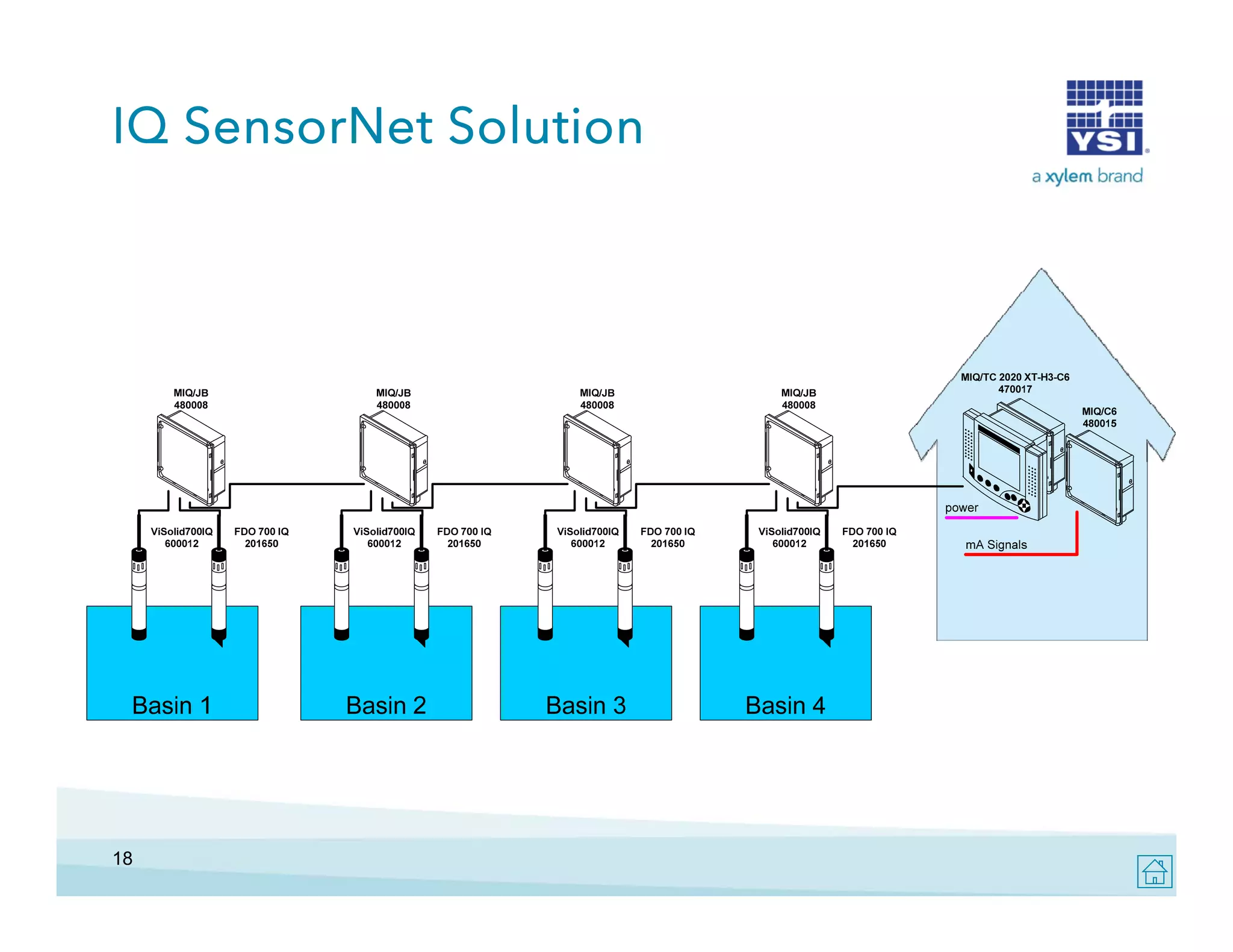

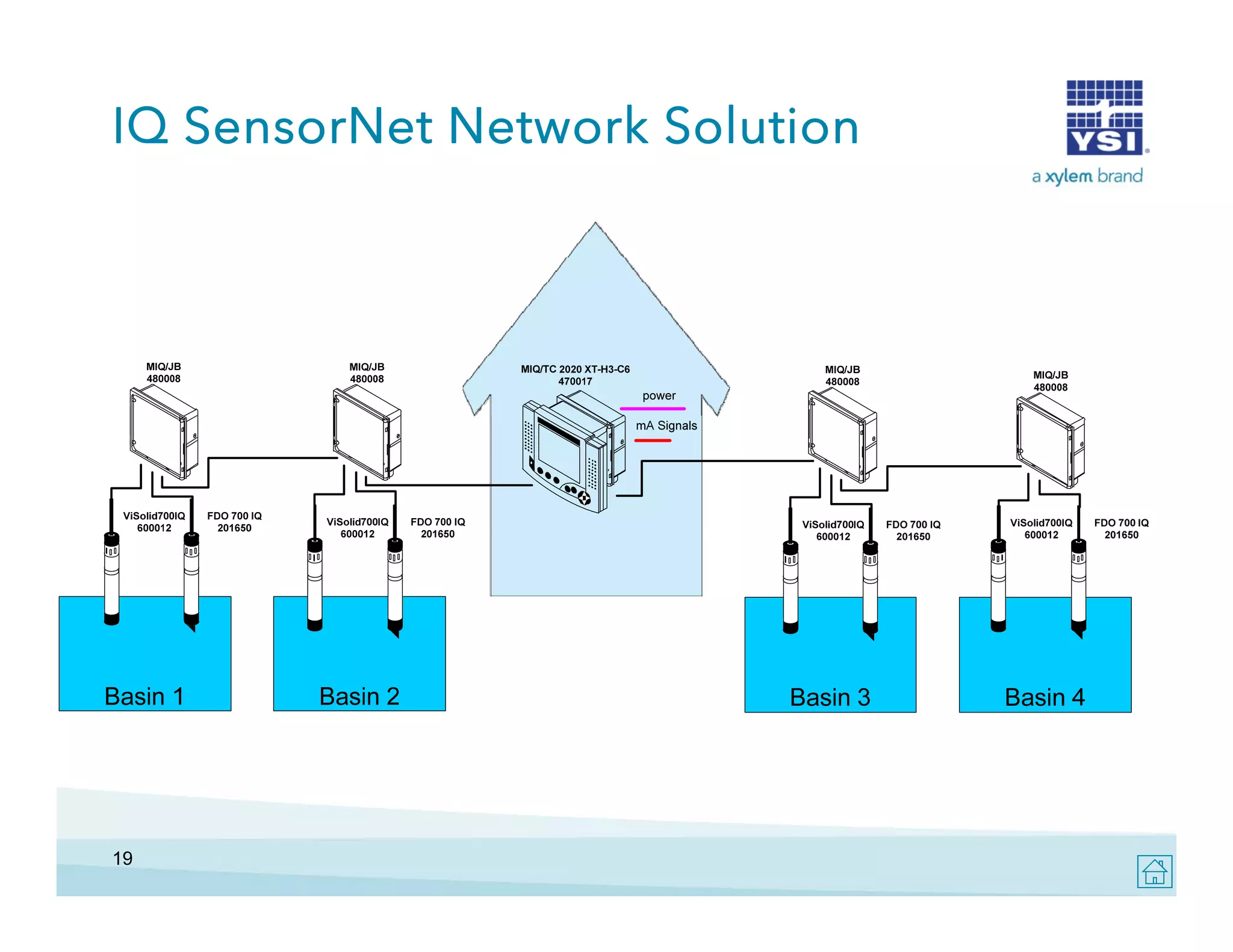

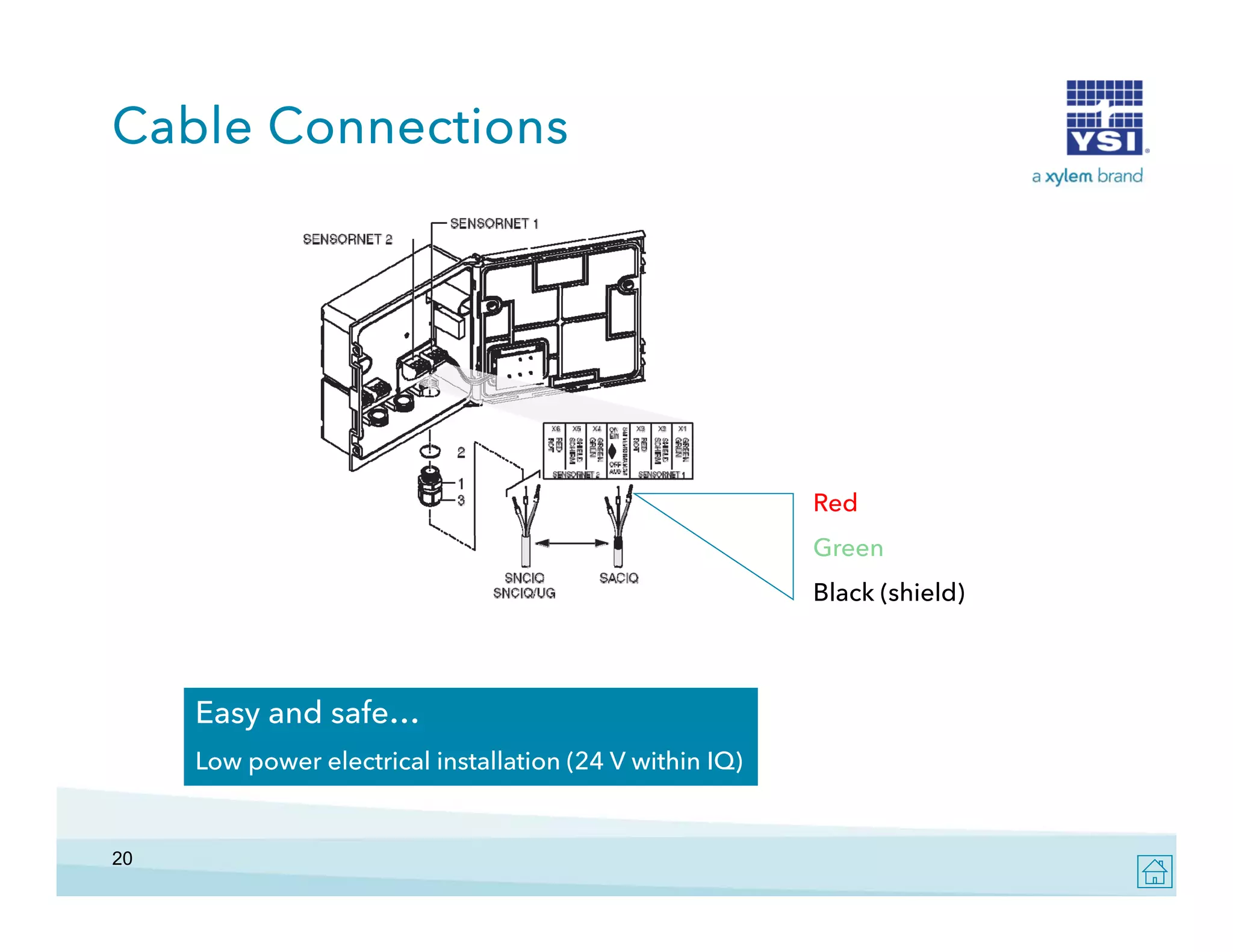

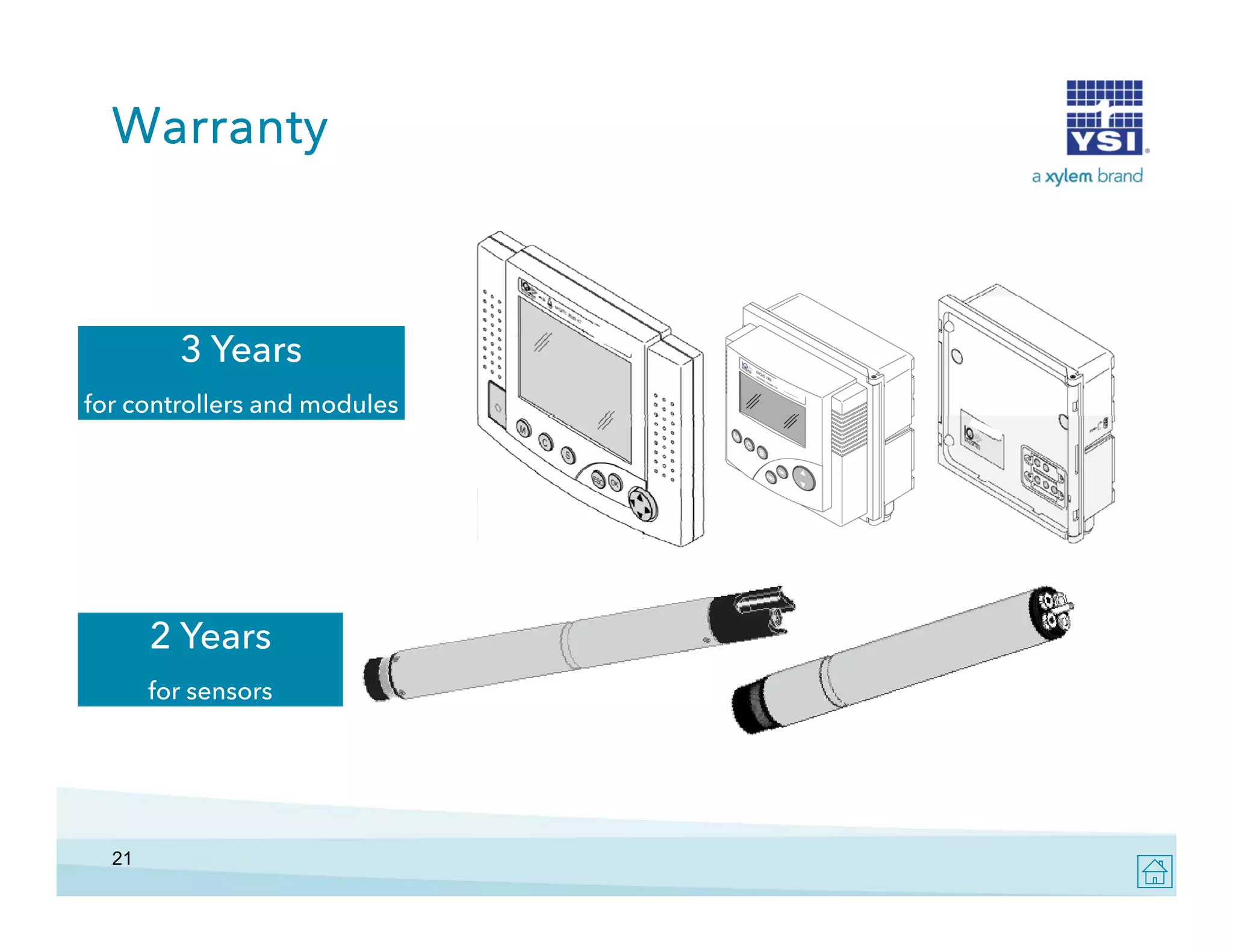

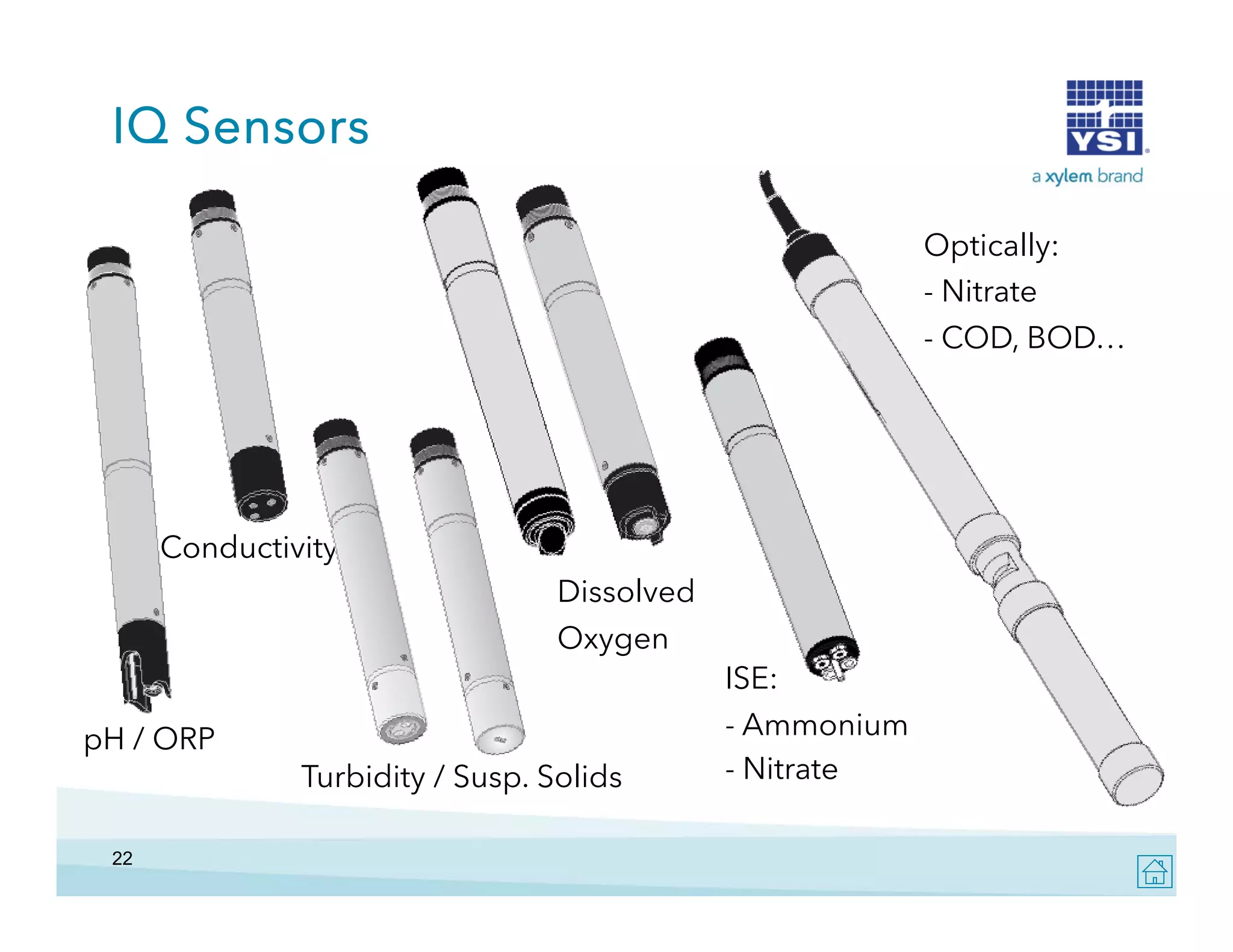

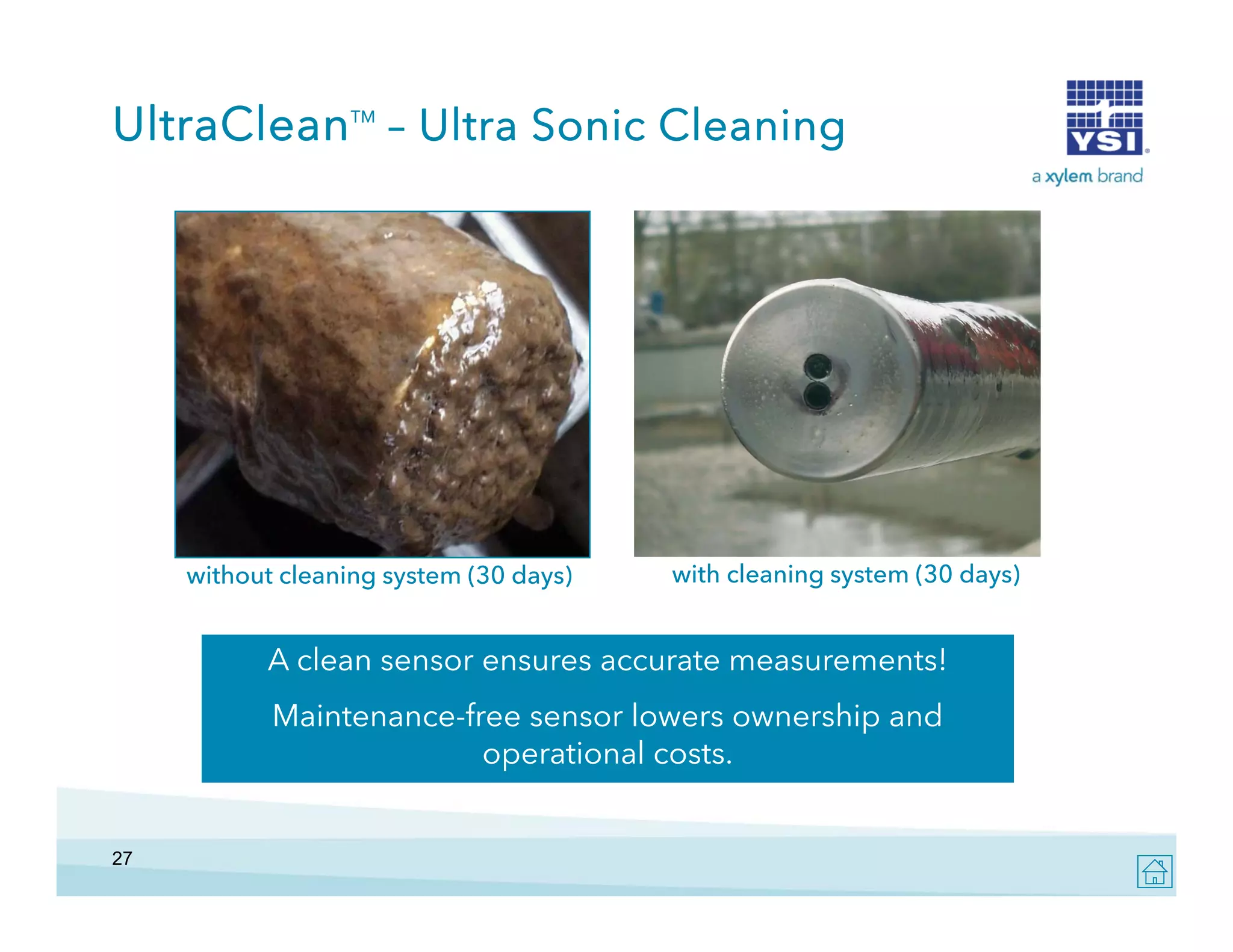

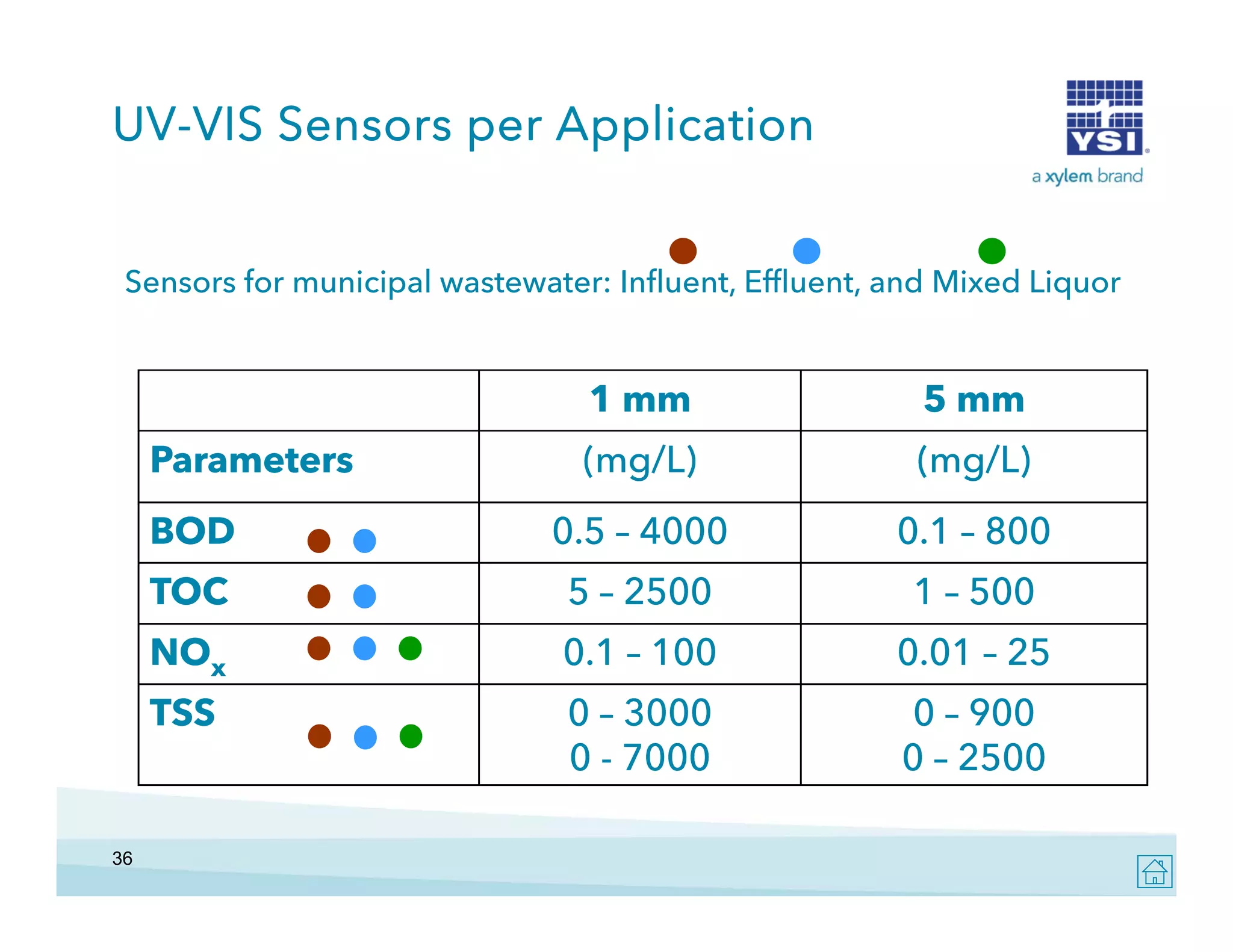

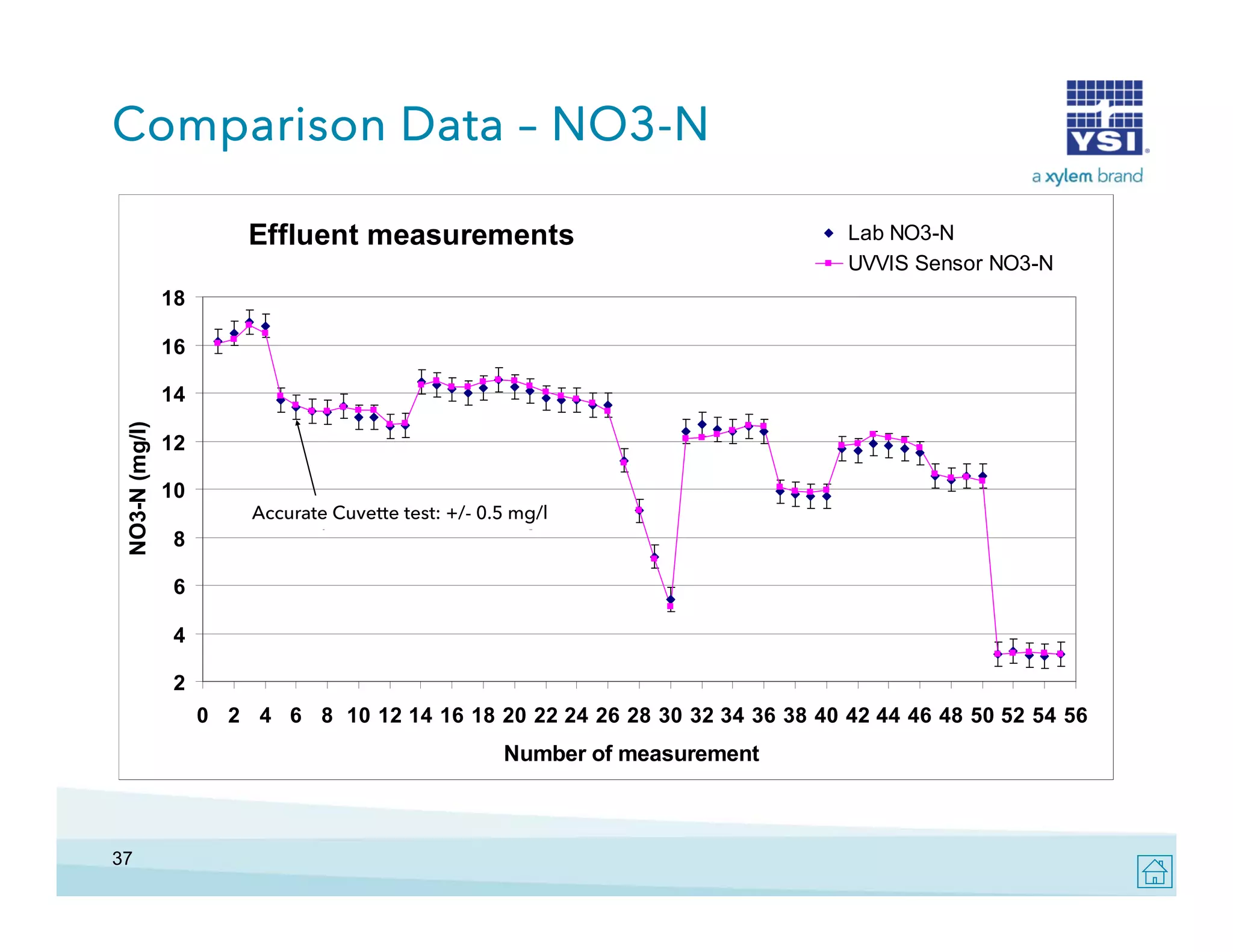

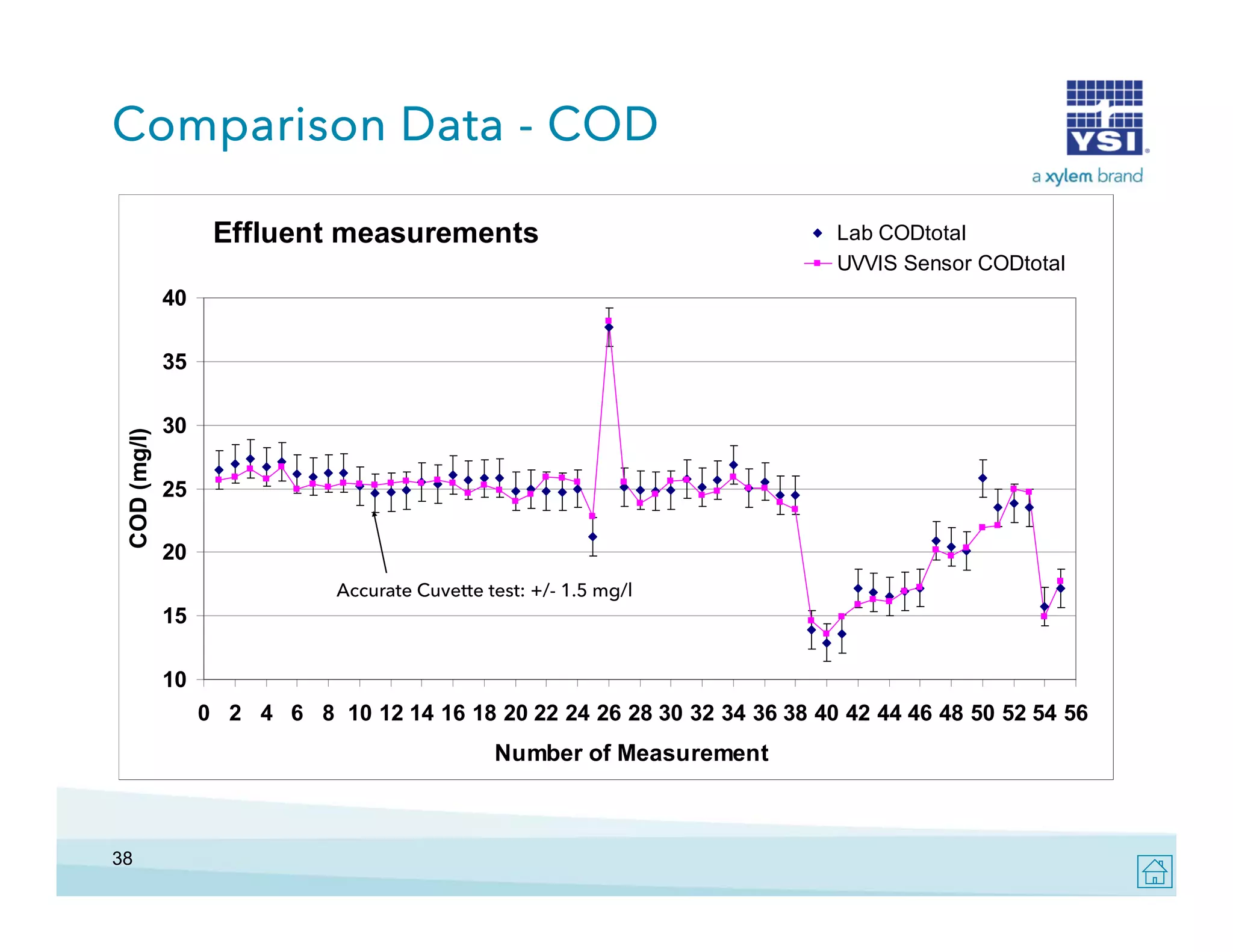

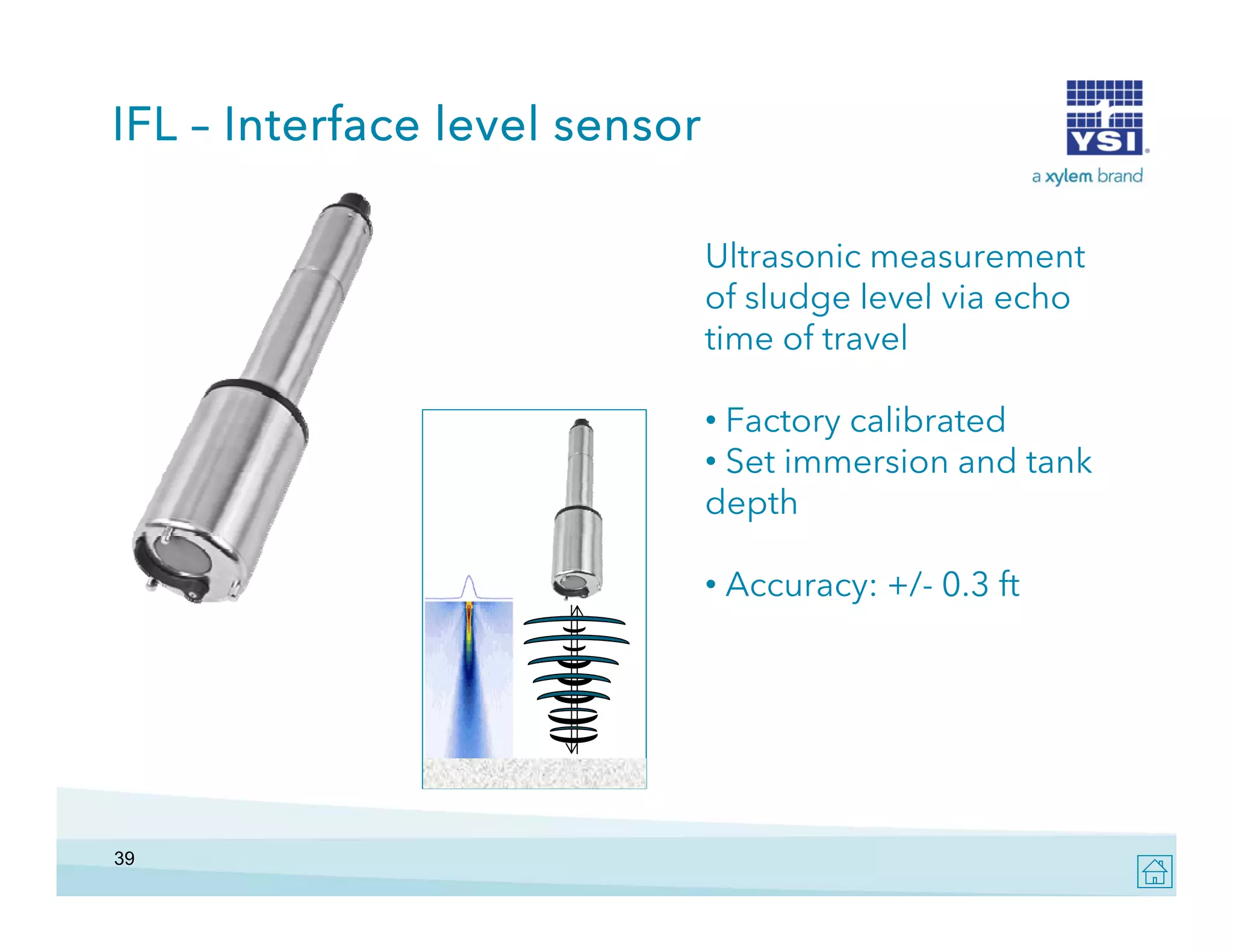

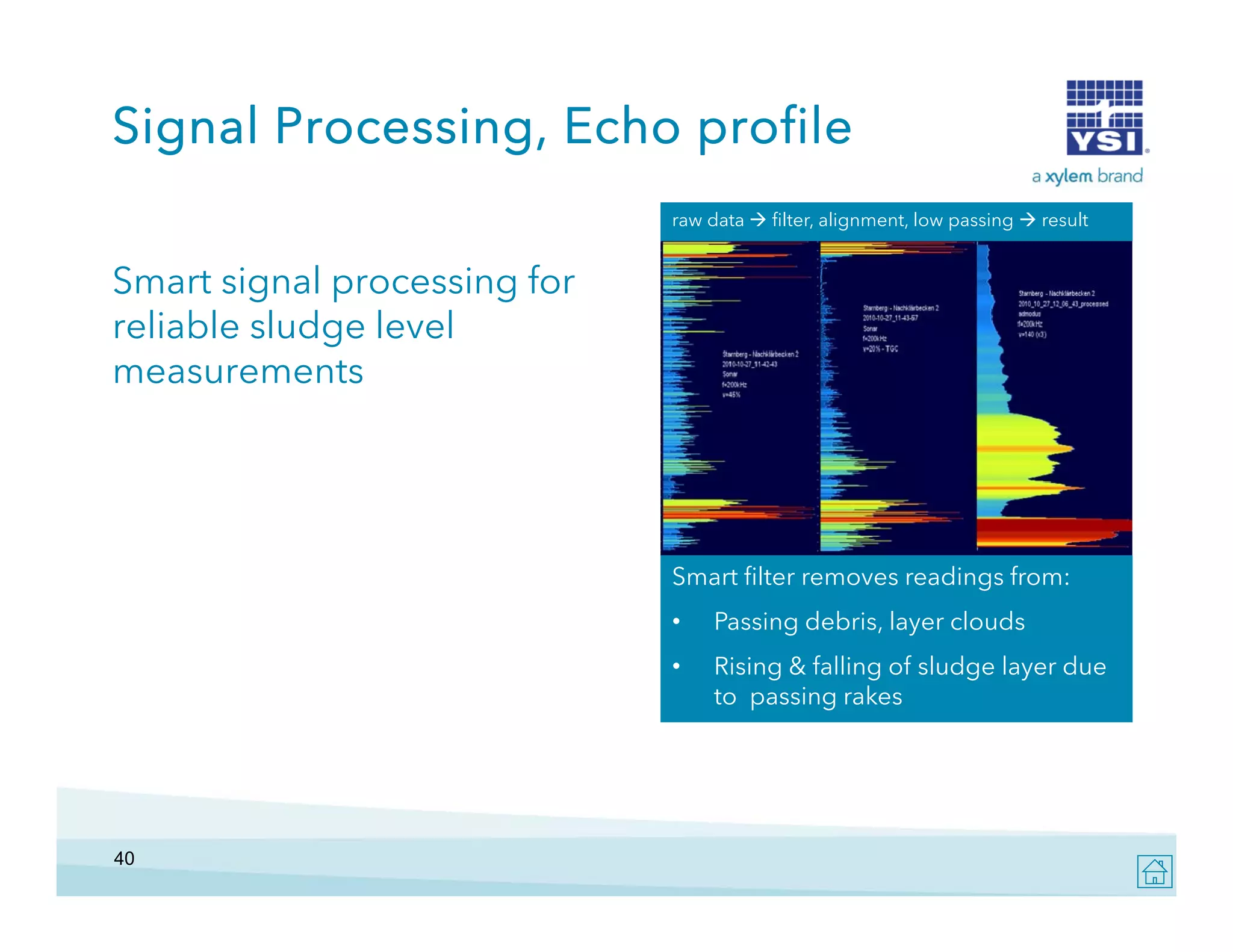

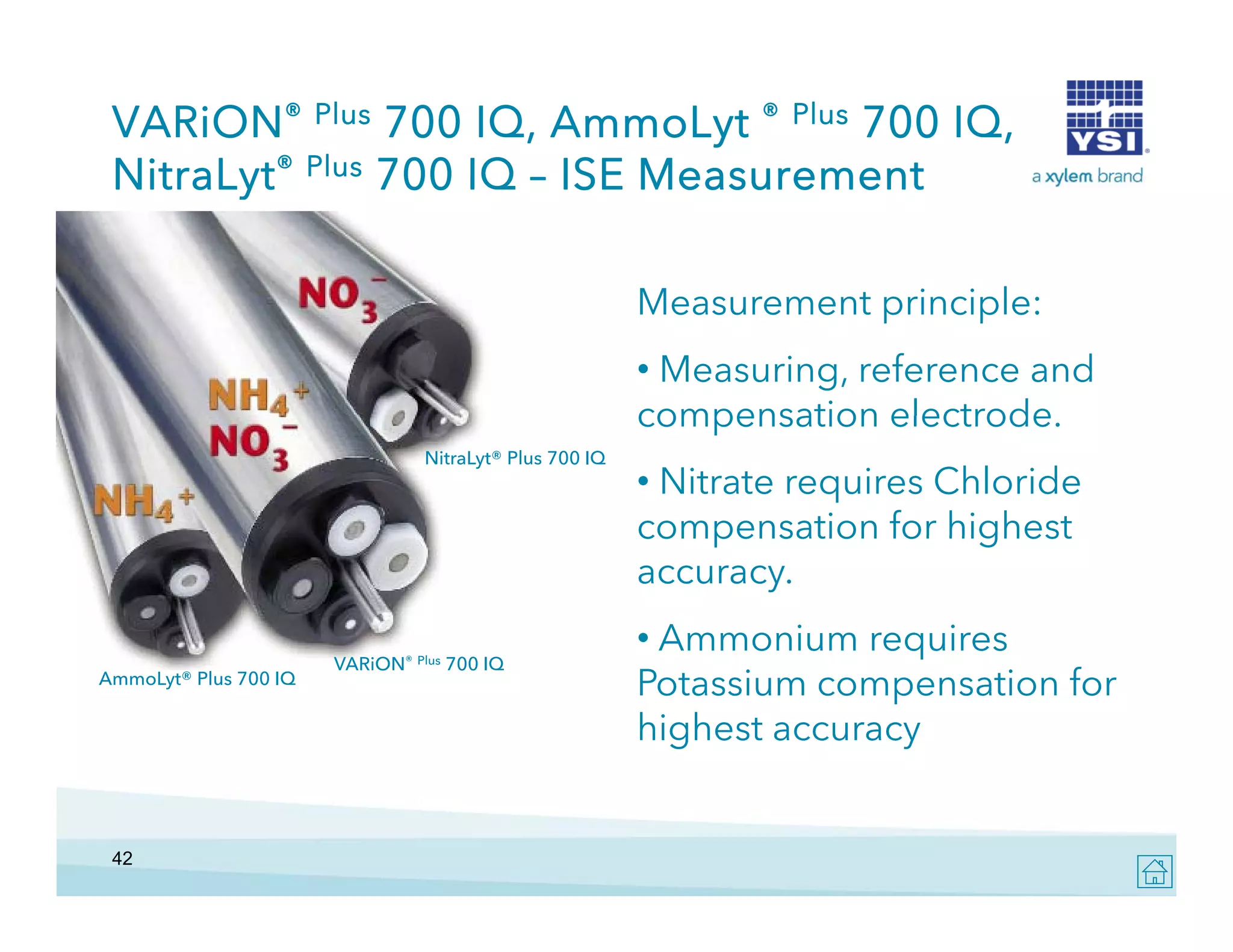

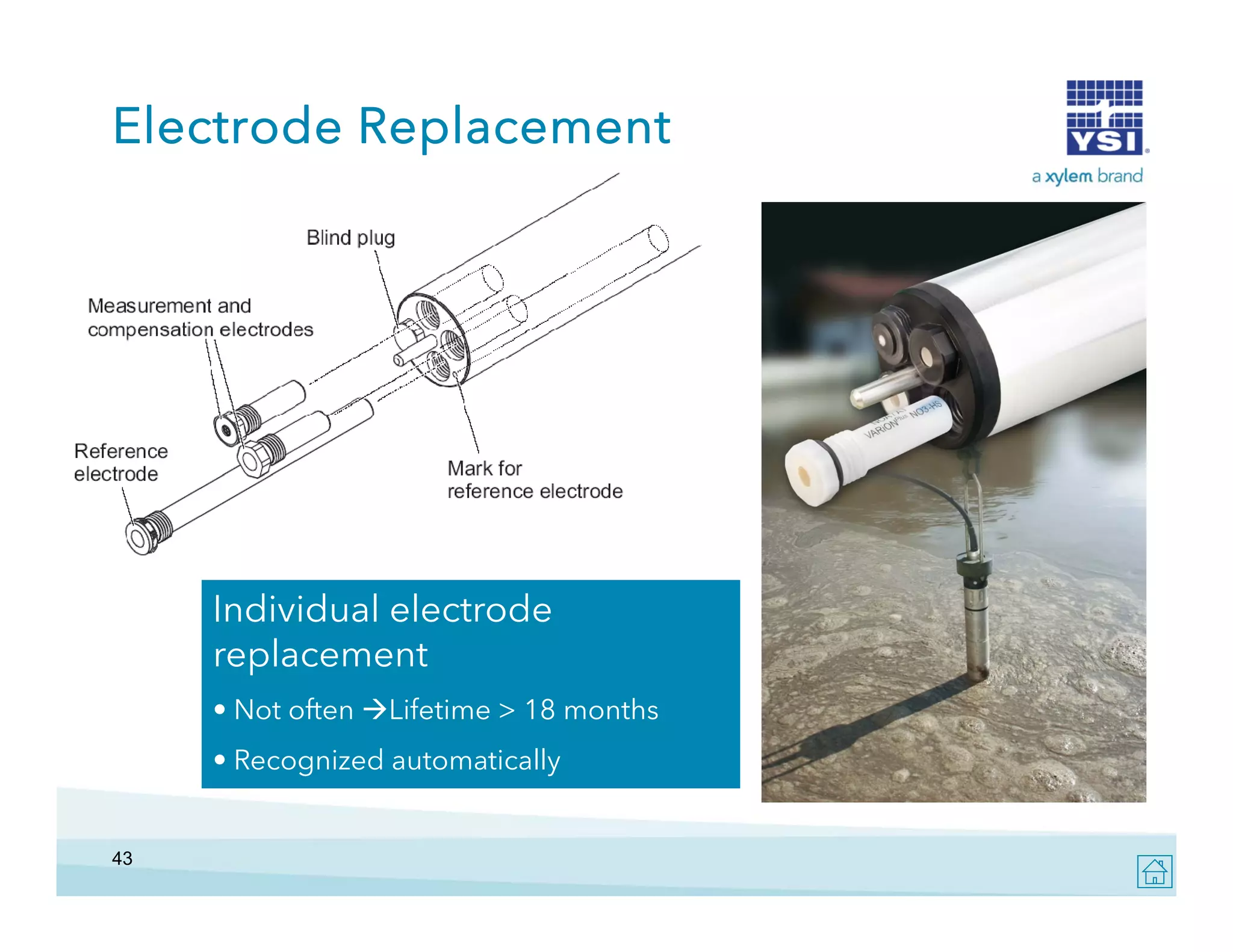

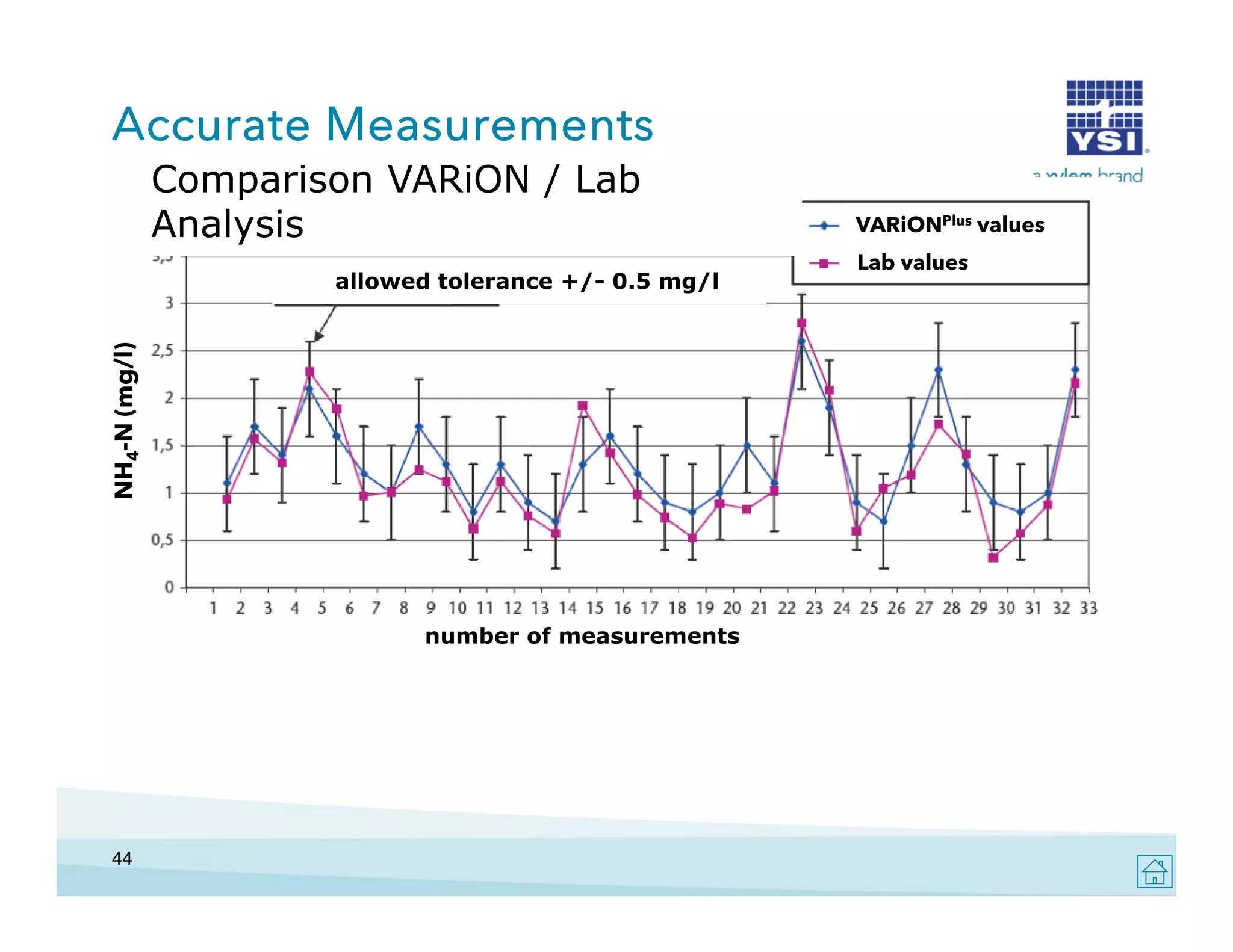

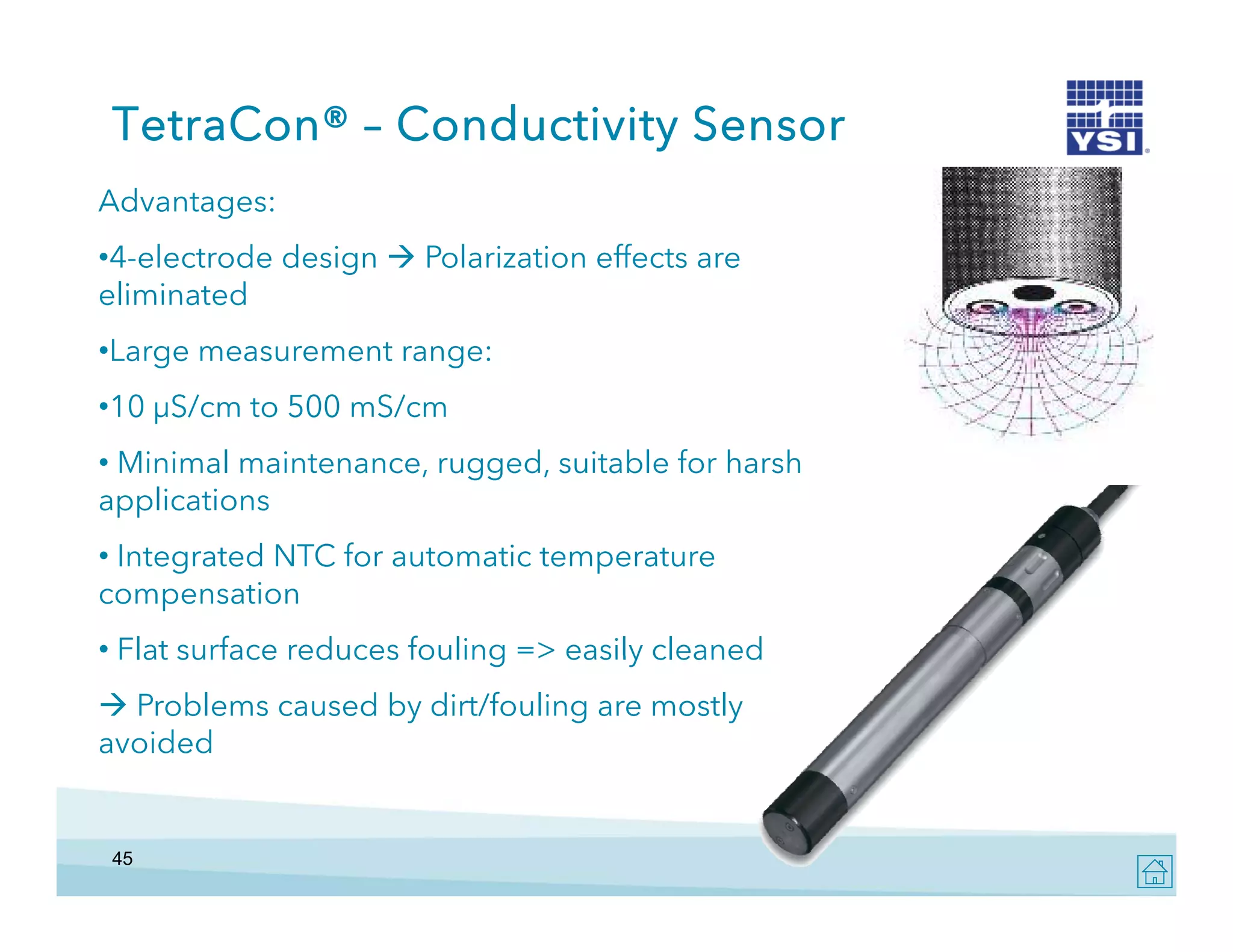

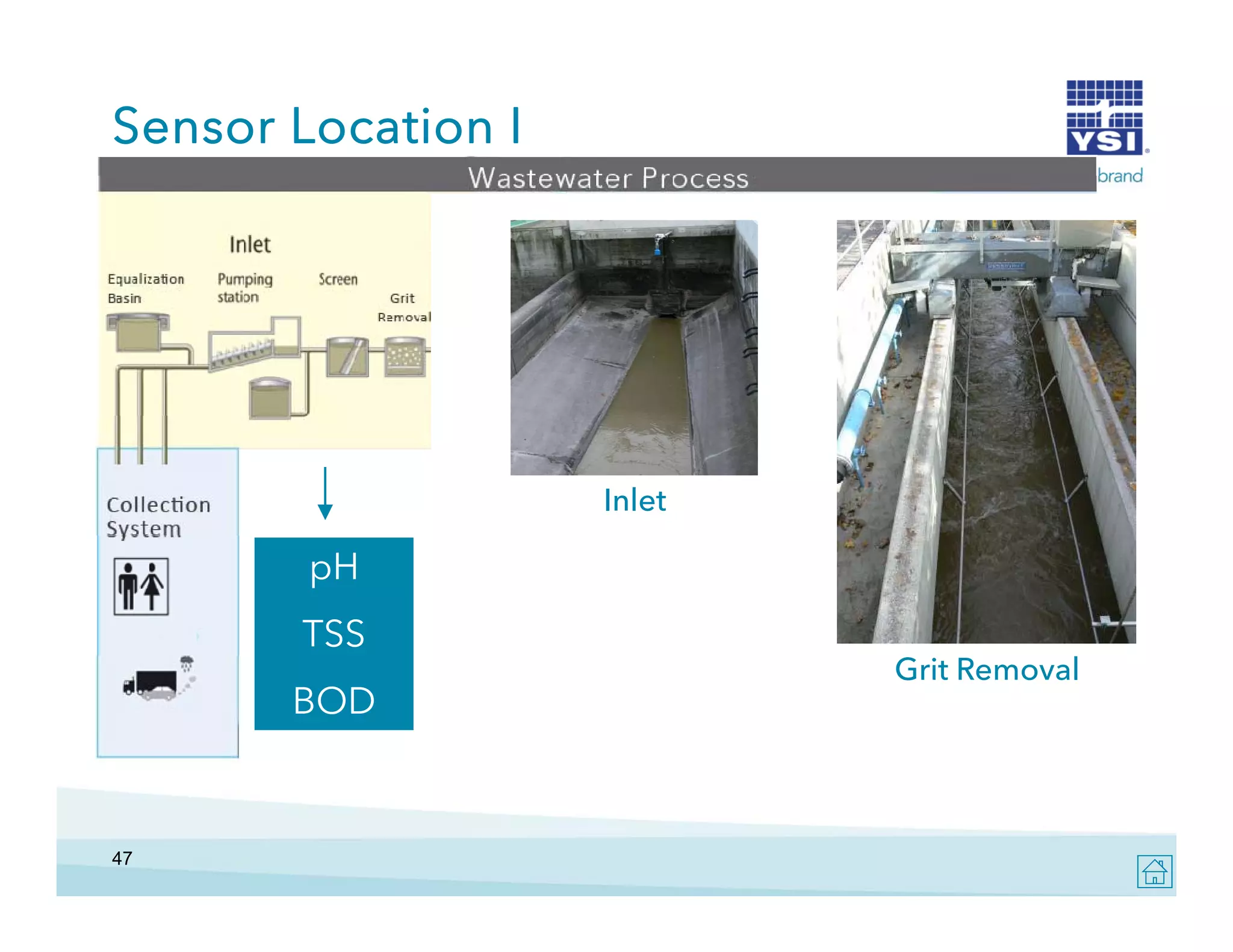

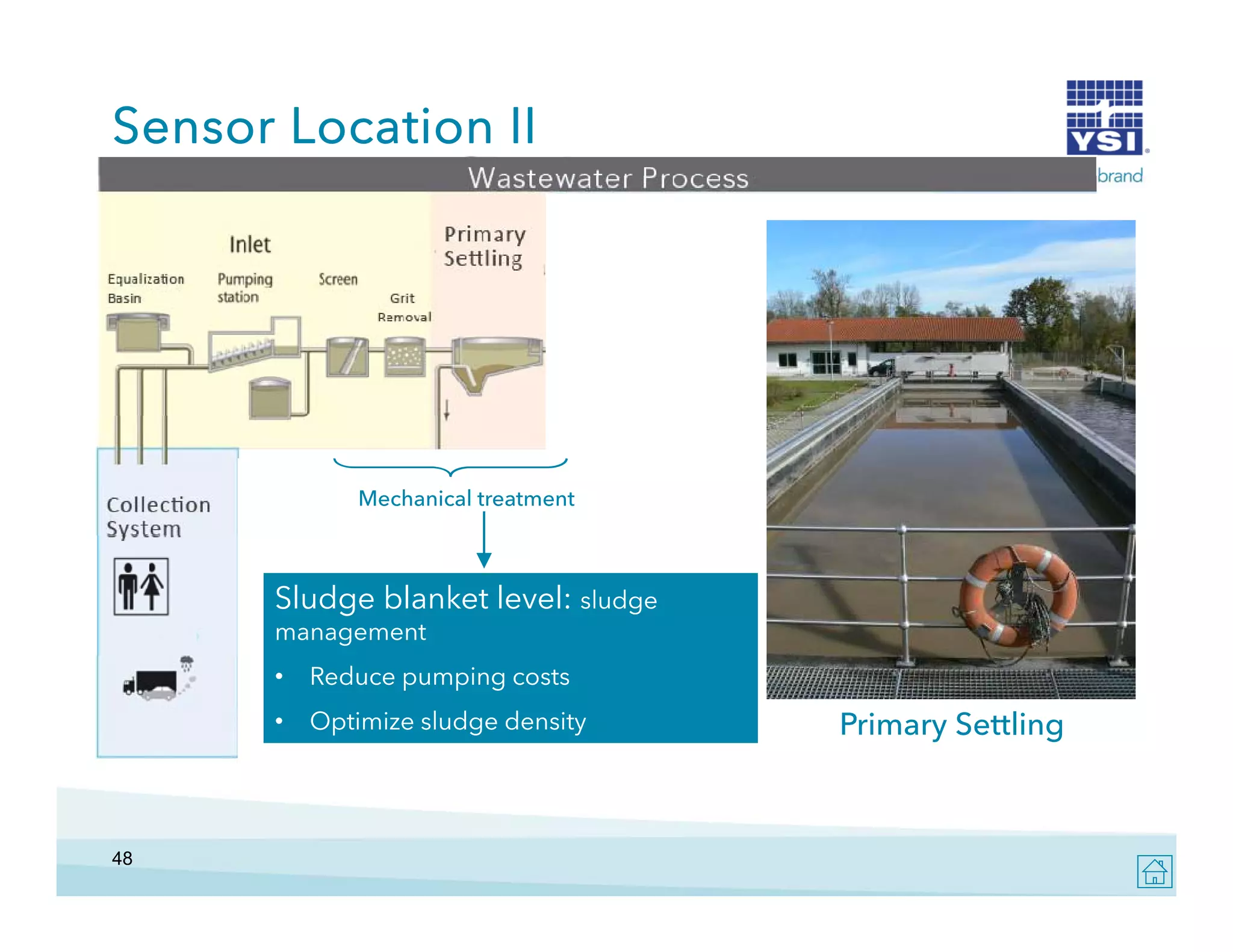

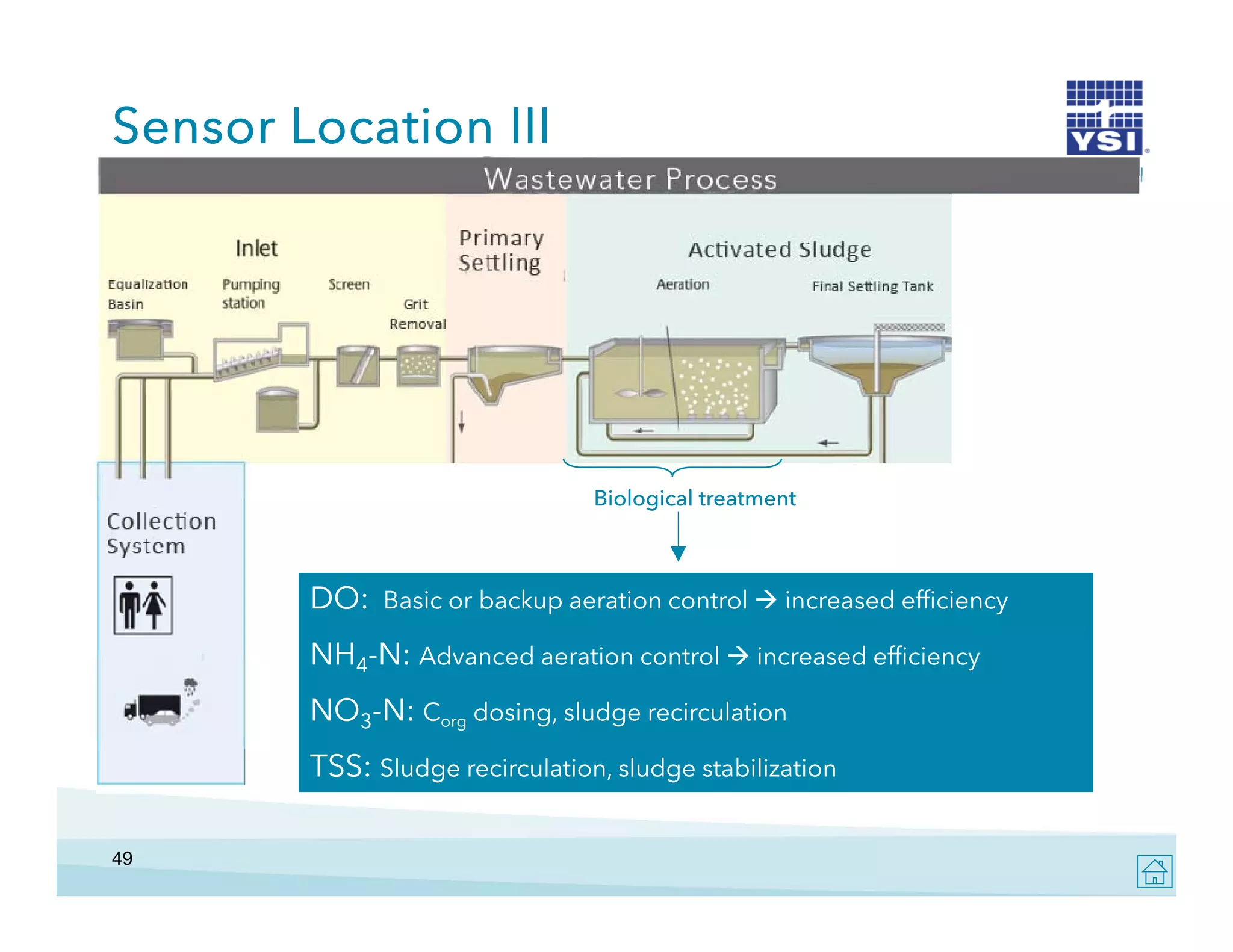

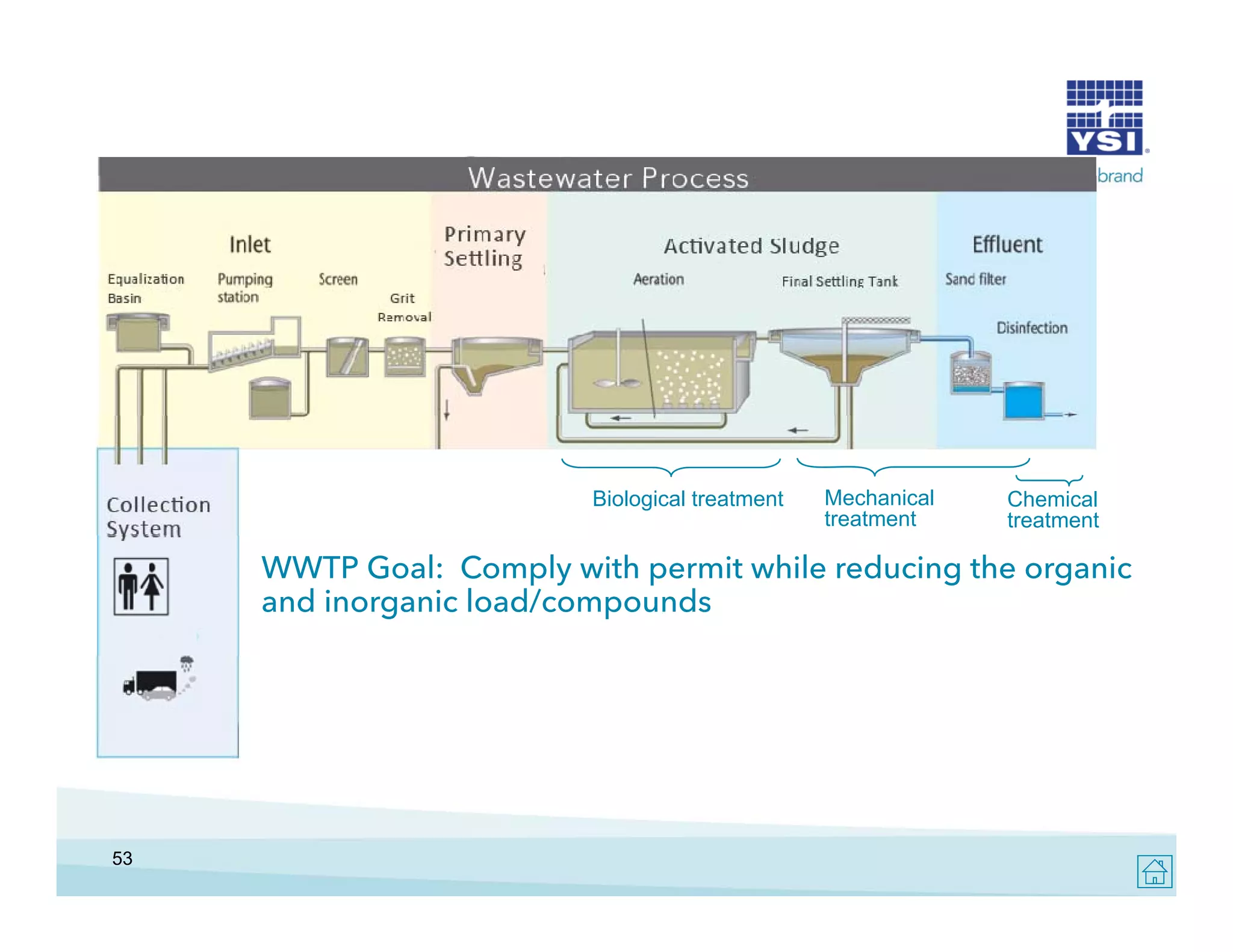

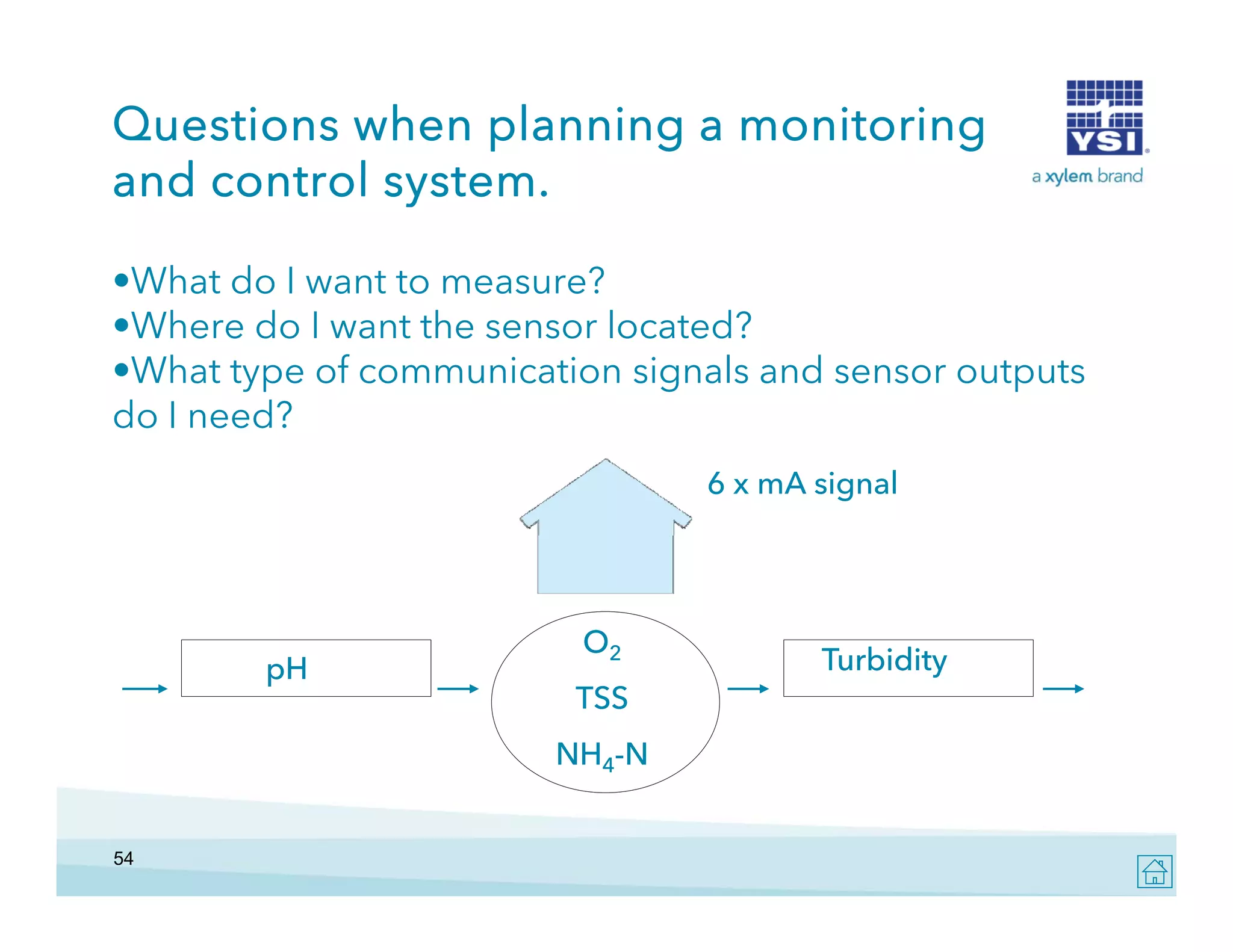

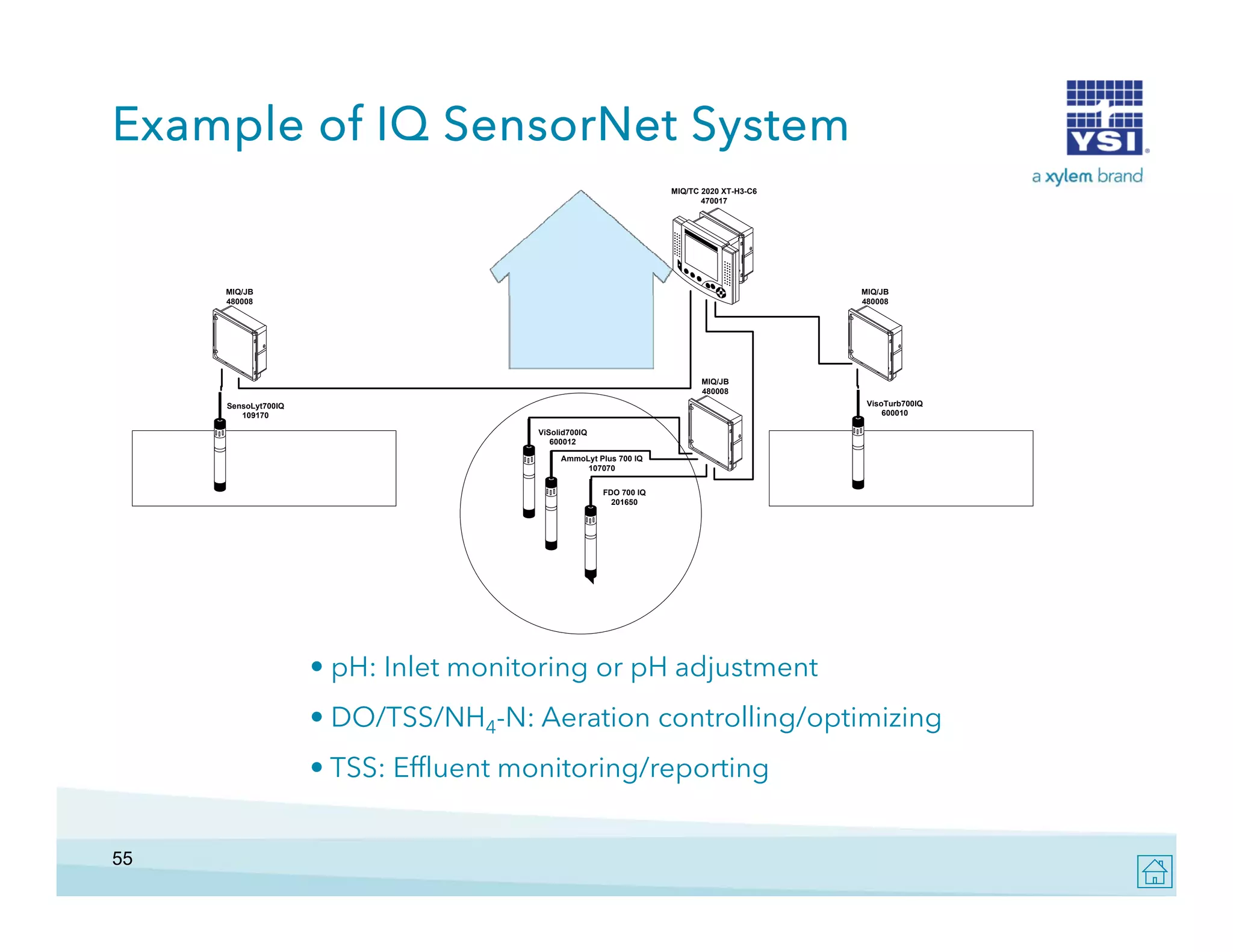

The document presents an overview of the IQ Sensornet continuous process monitoring and control instrumentation, highlighting the features and components of the 2020 XT controller system. It details the capabilities of various sensors, communication interfaces, and maintenance-free functionalities, emphasizing the importance of accurate measurements in wastewater management. The presentation also outlines typical installations, applications, and YSI's commitment to supporting water professionals.