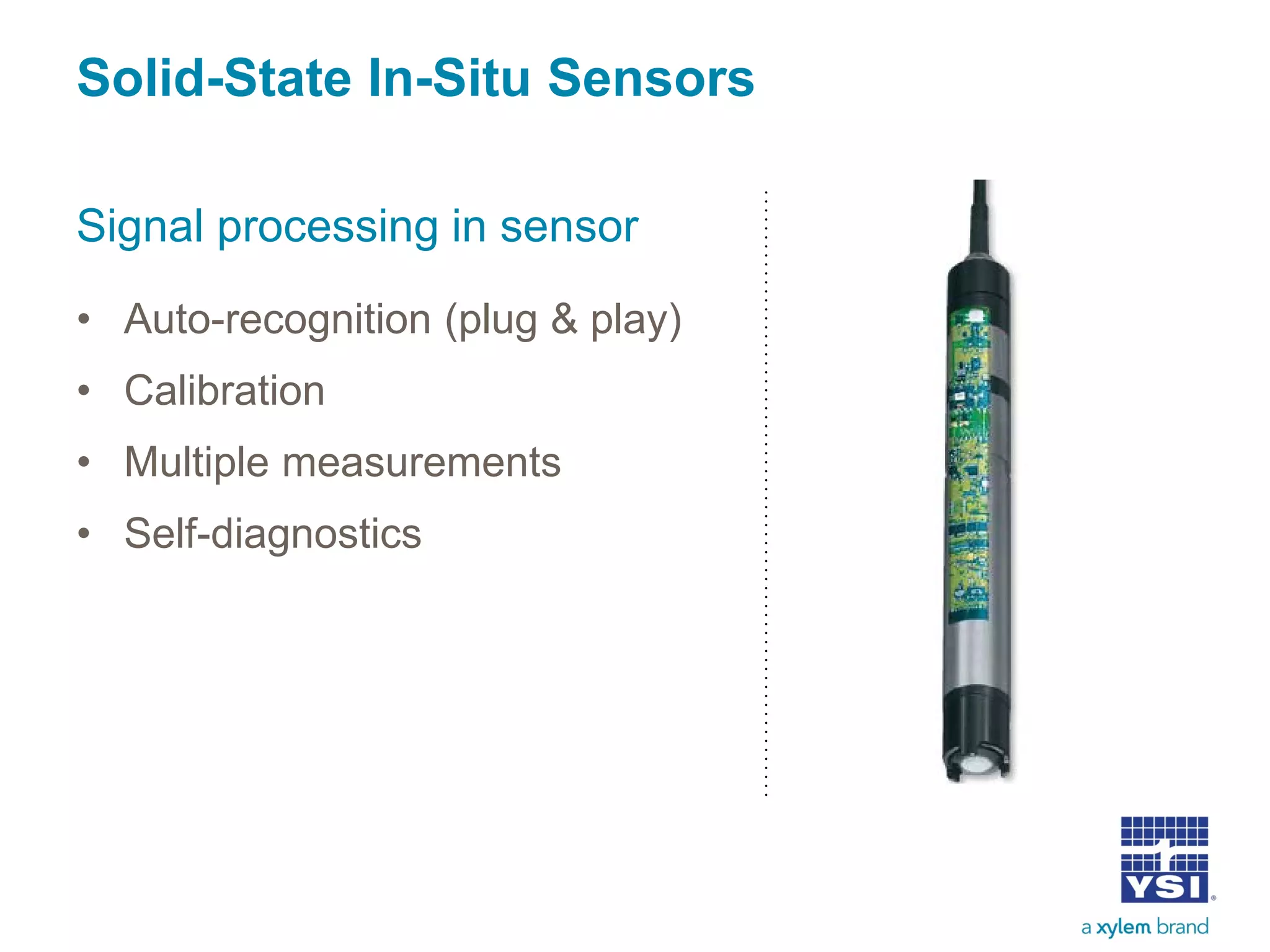

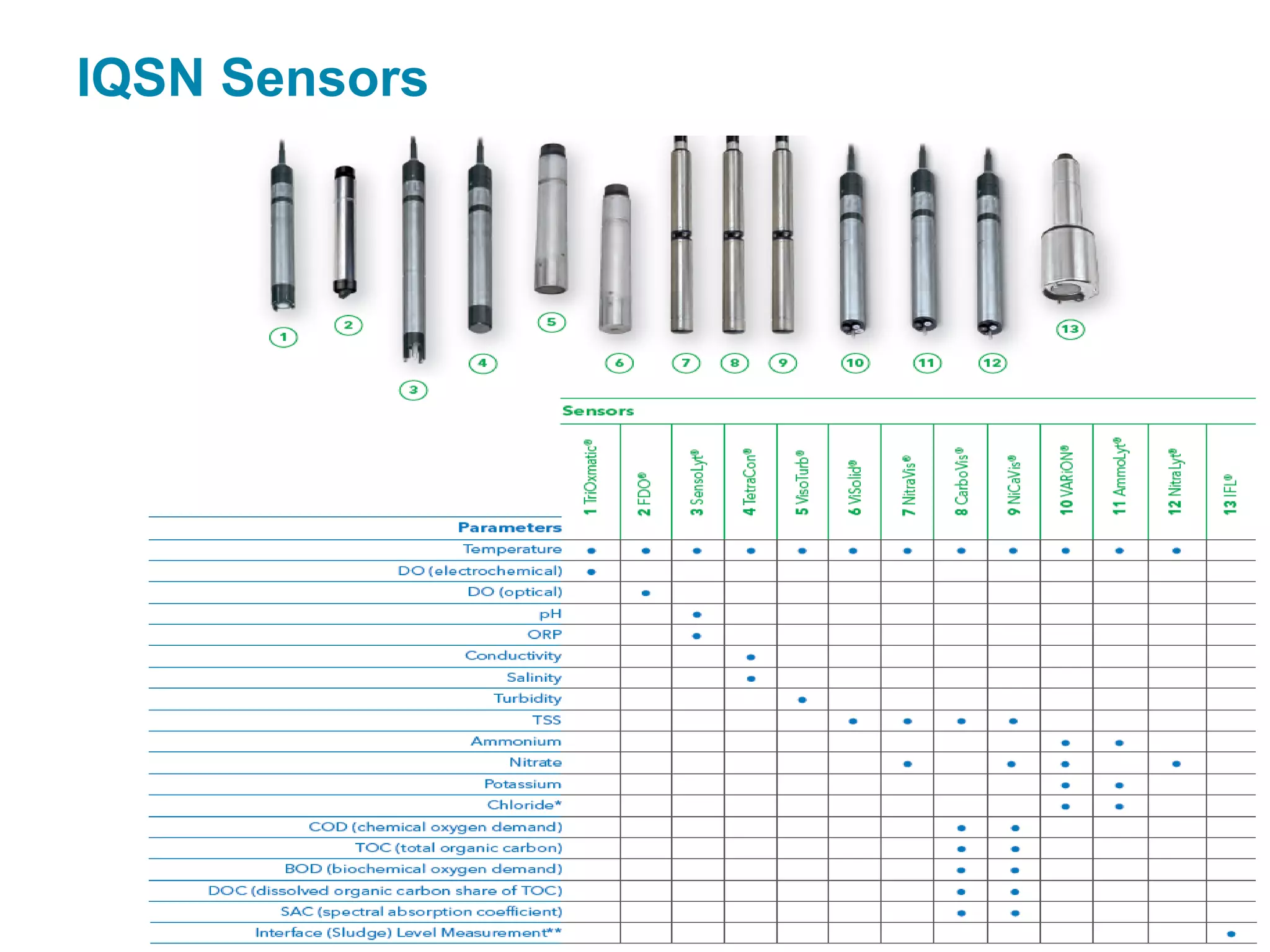

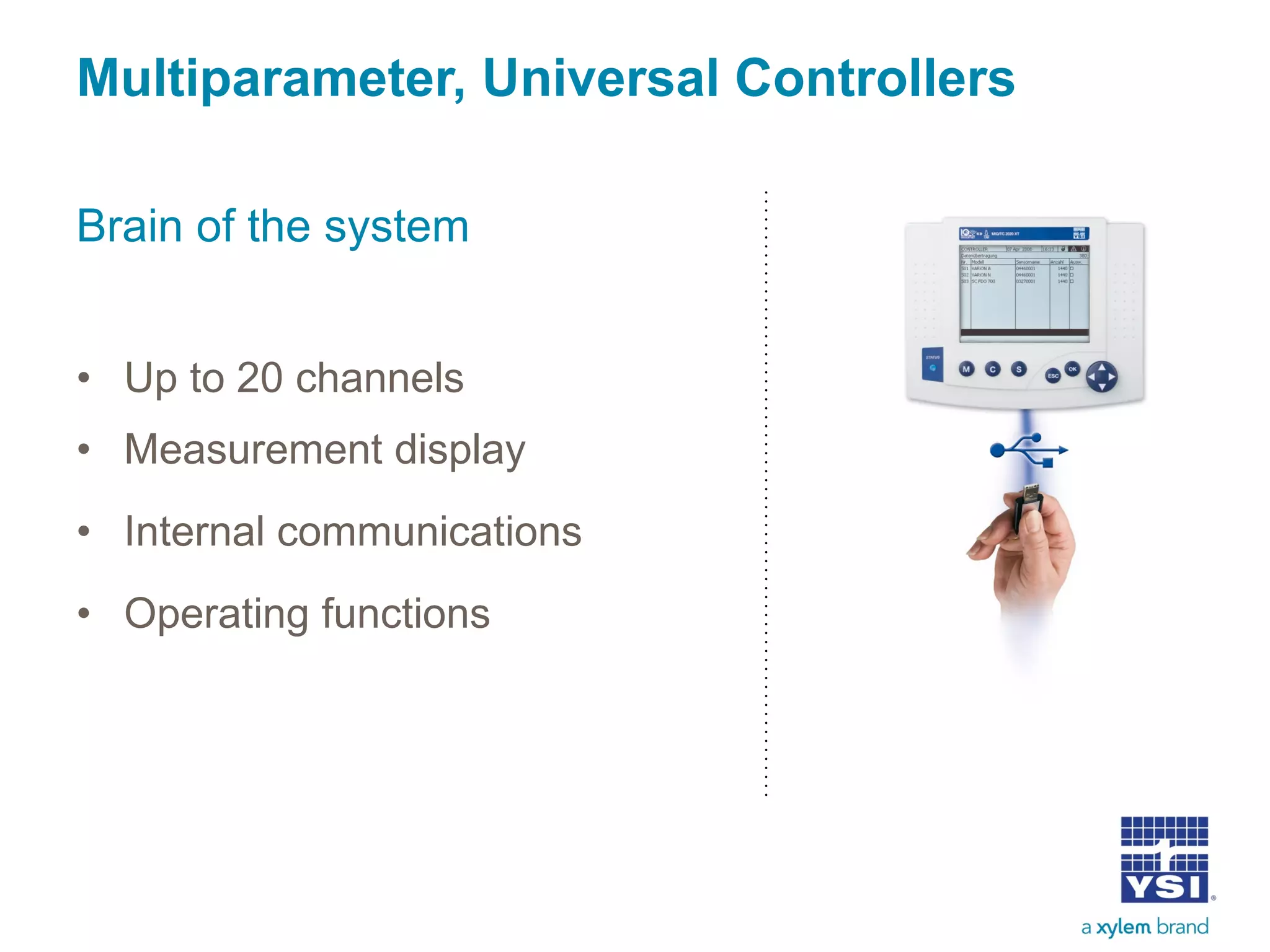

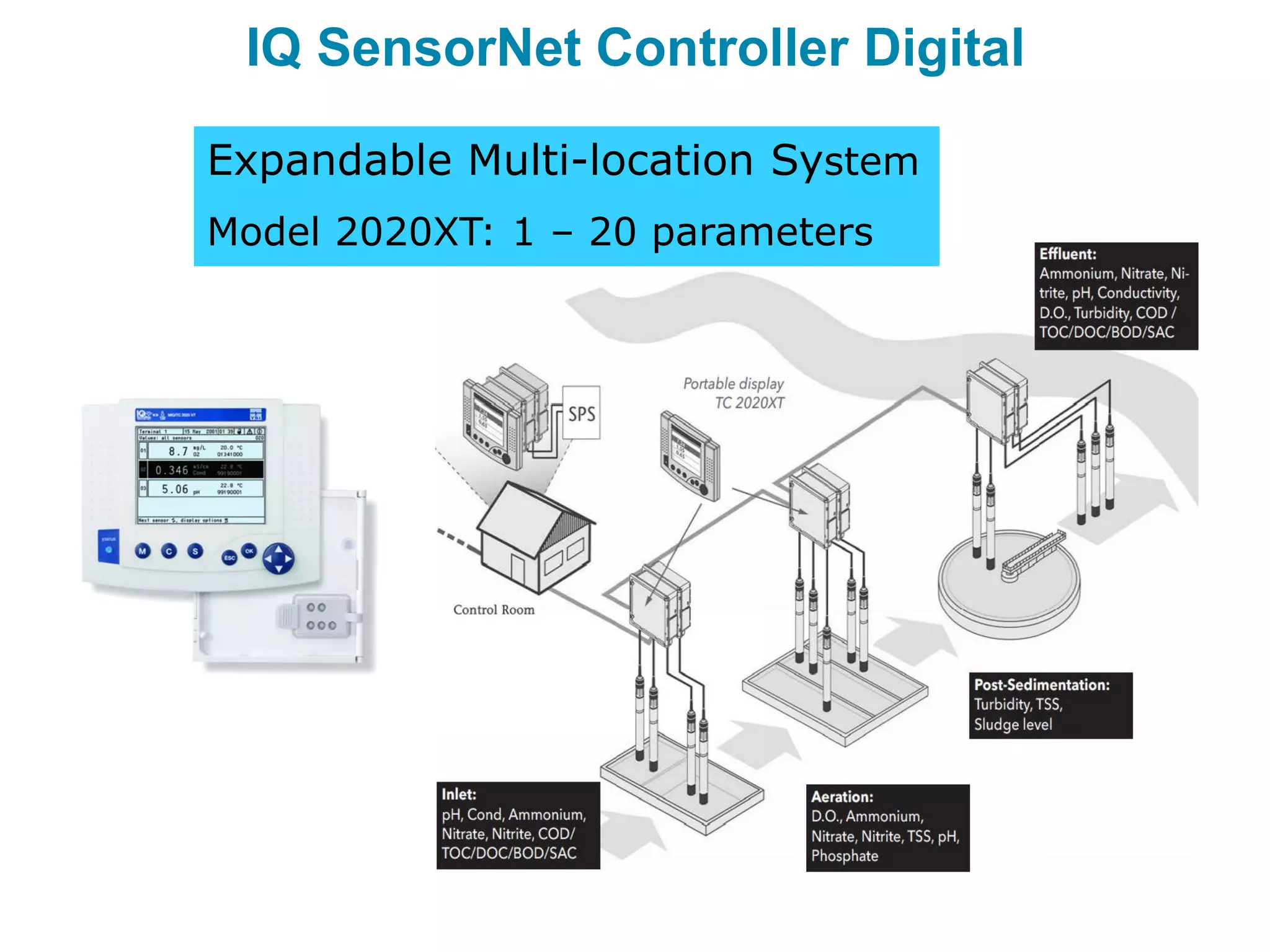

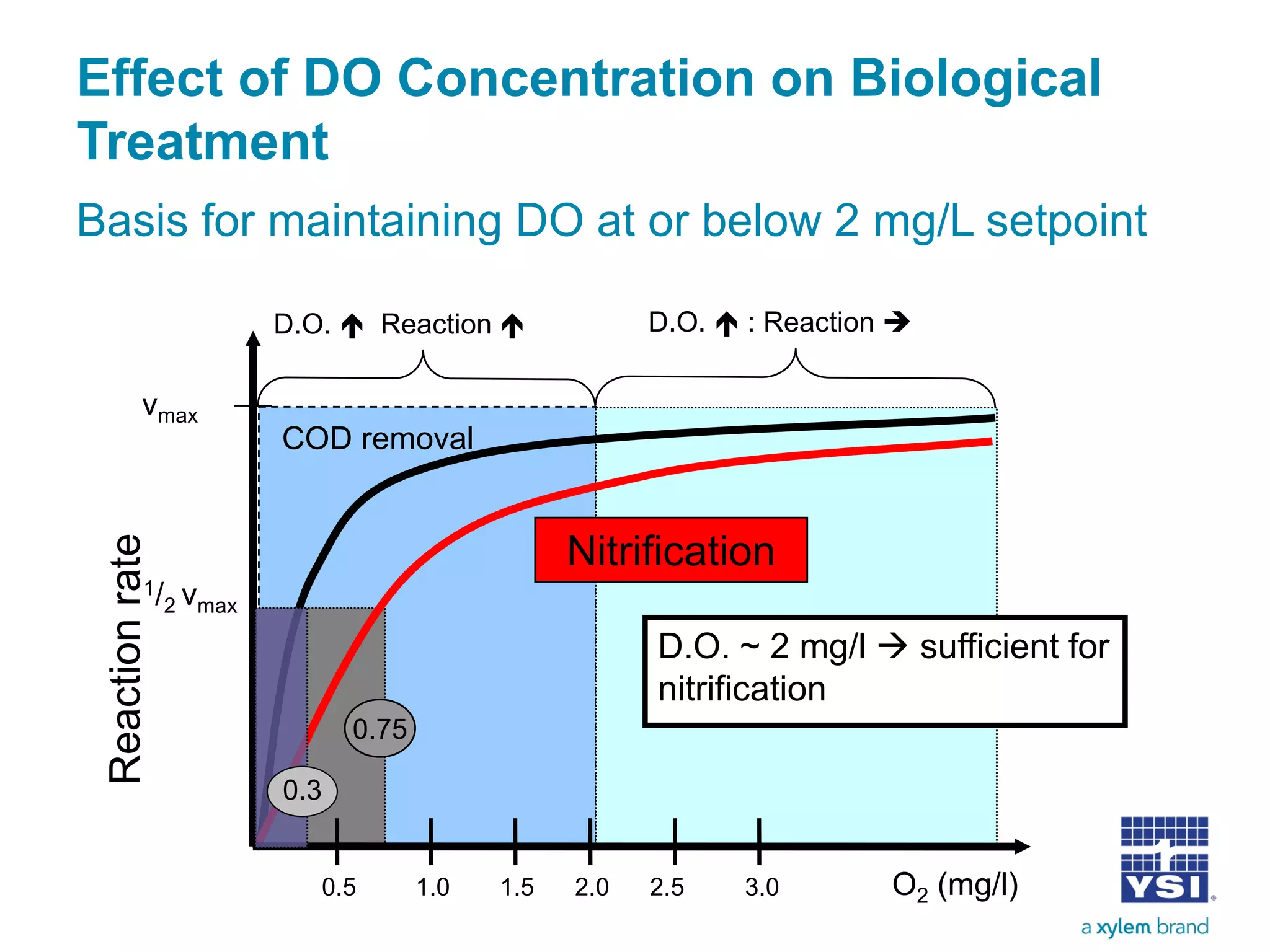

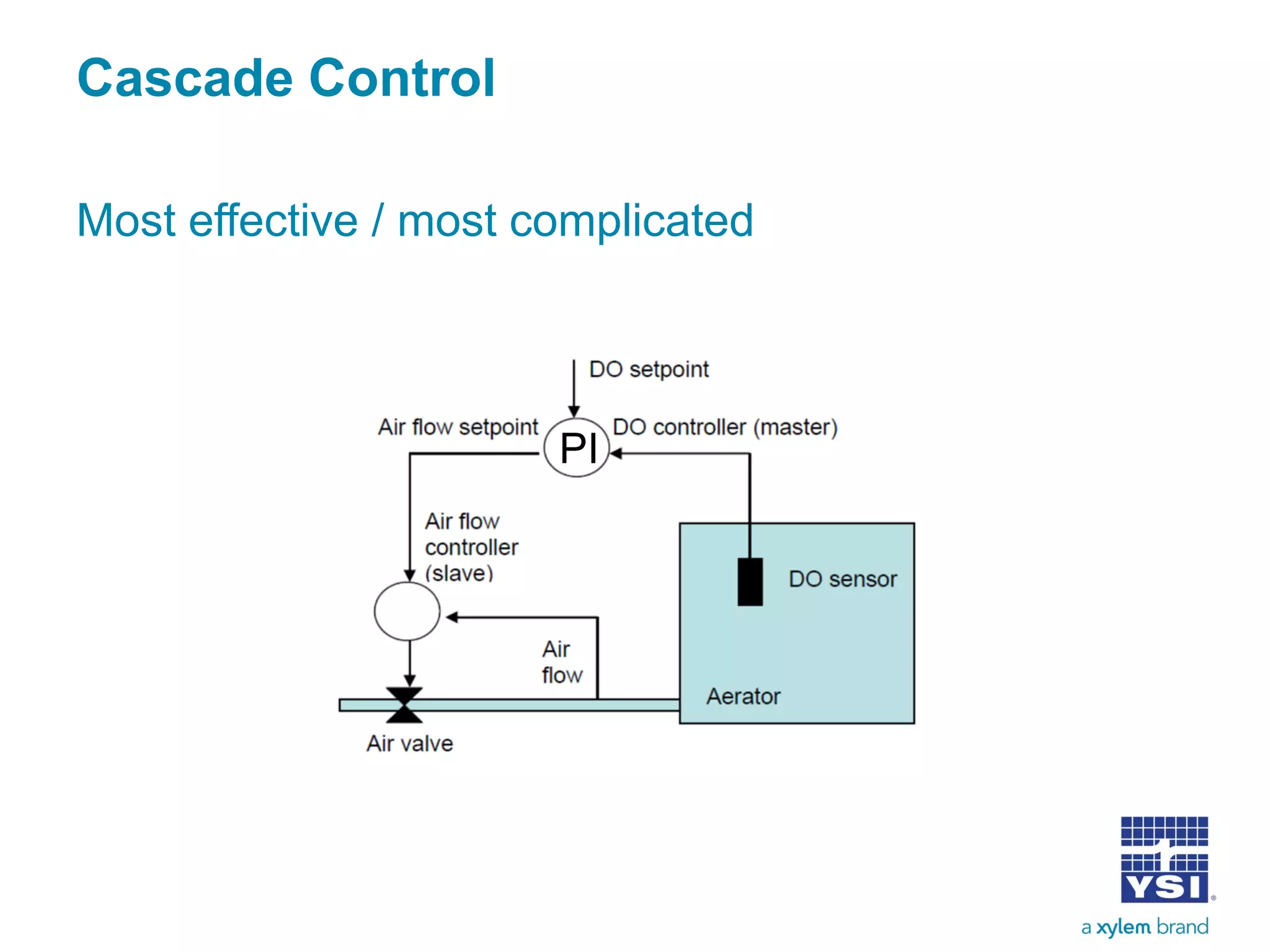

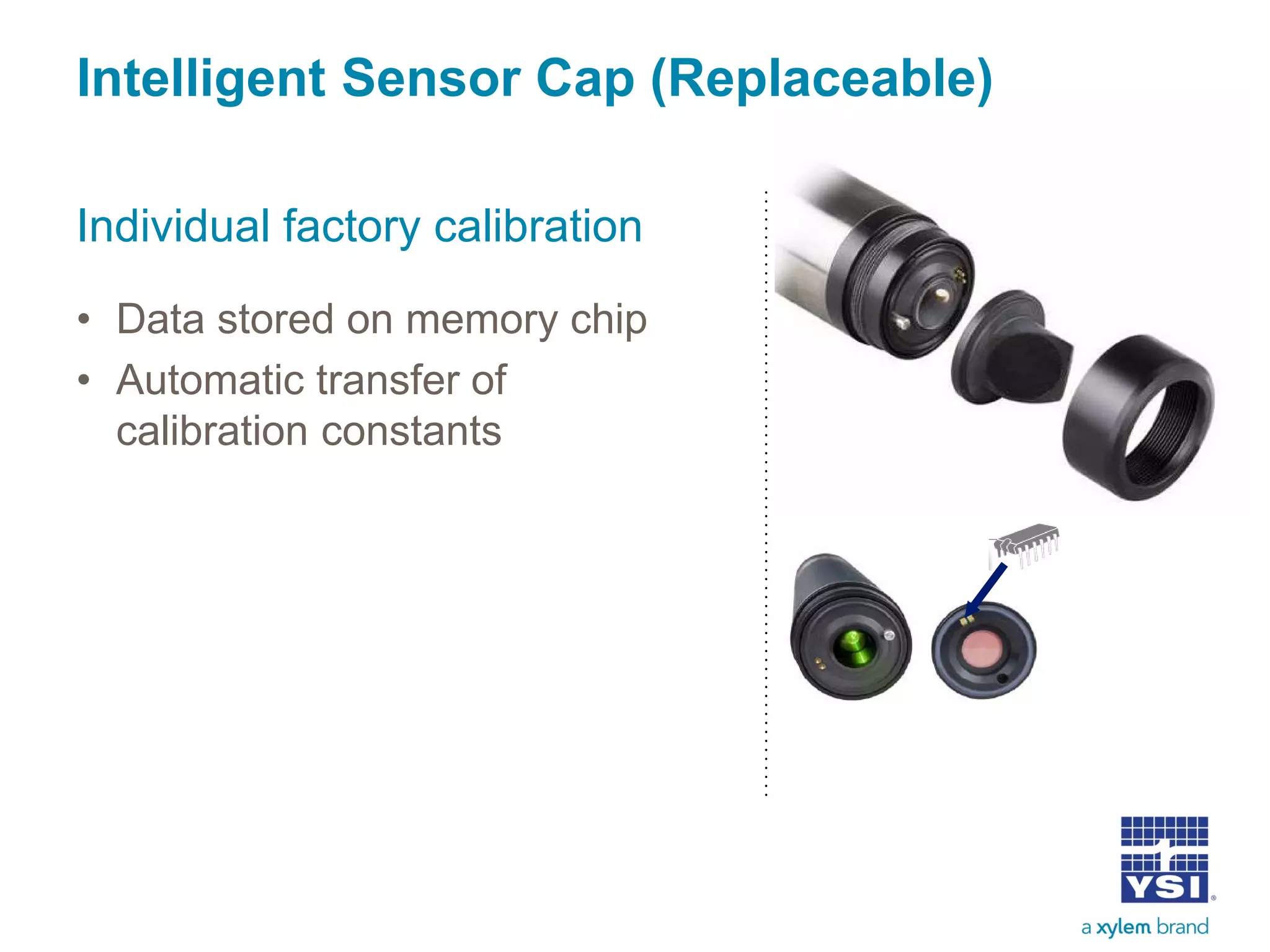

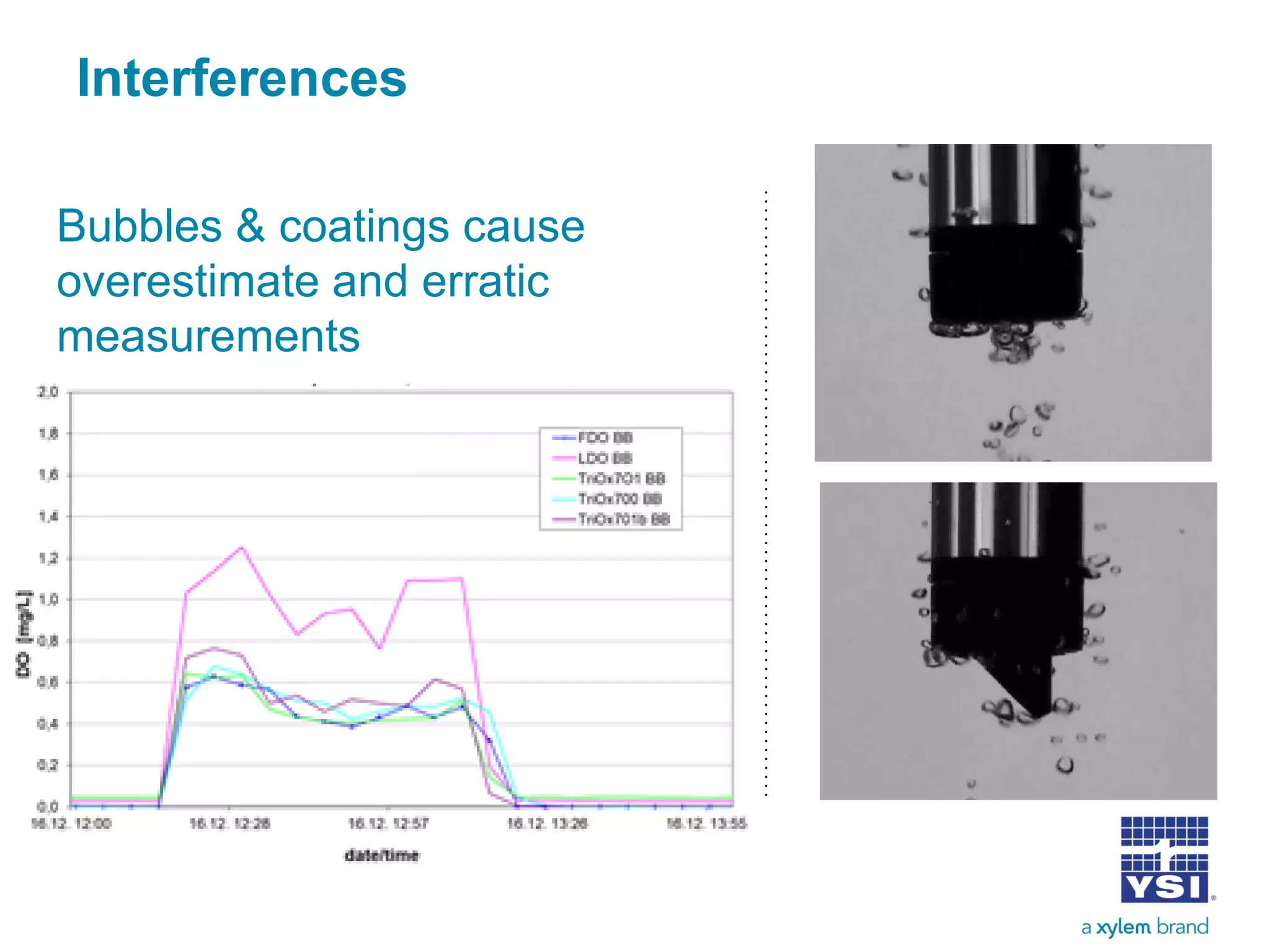

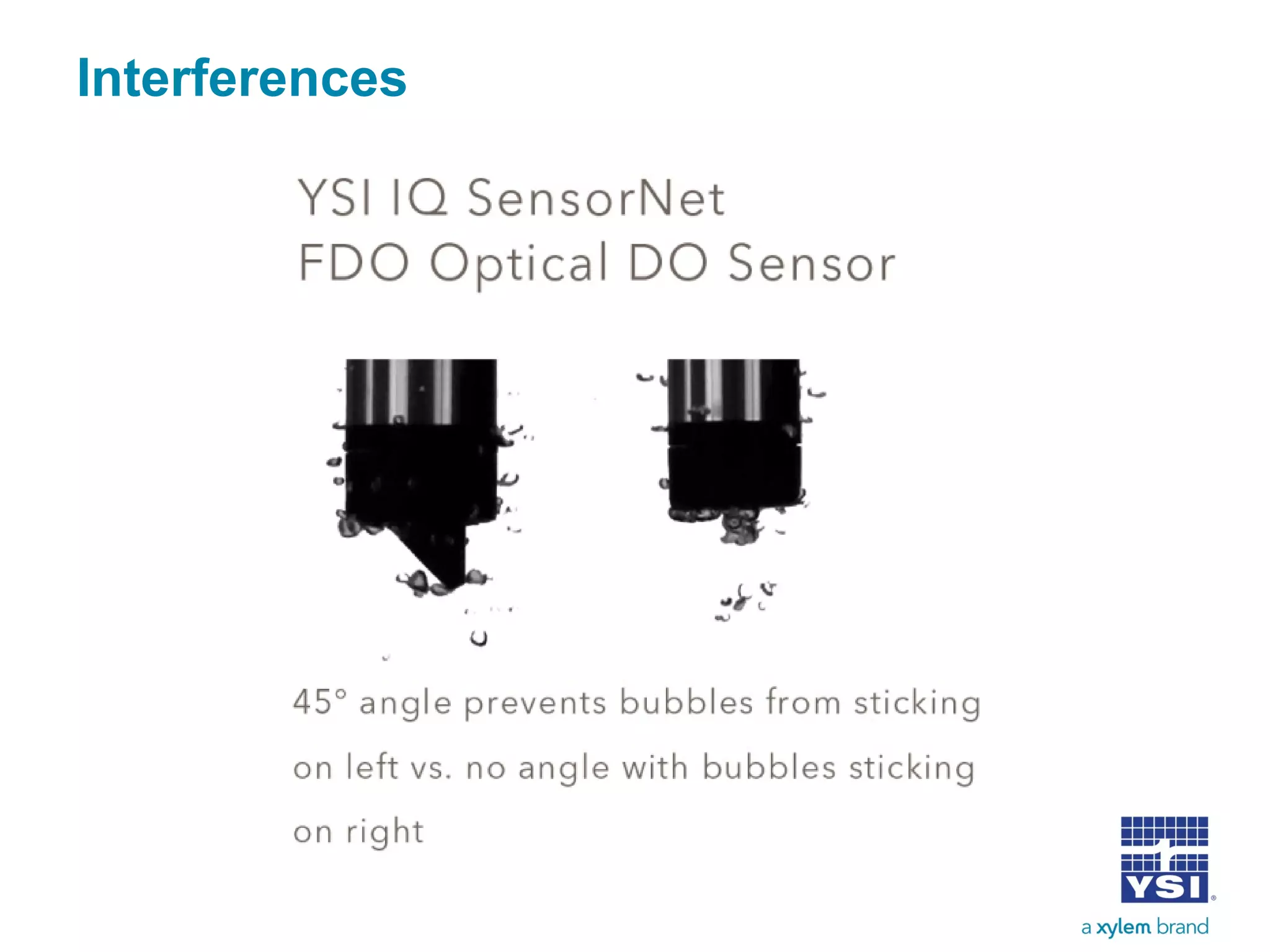

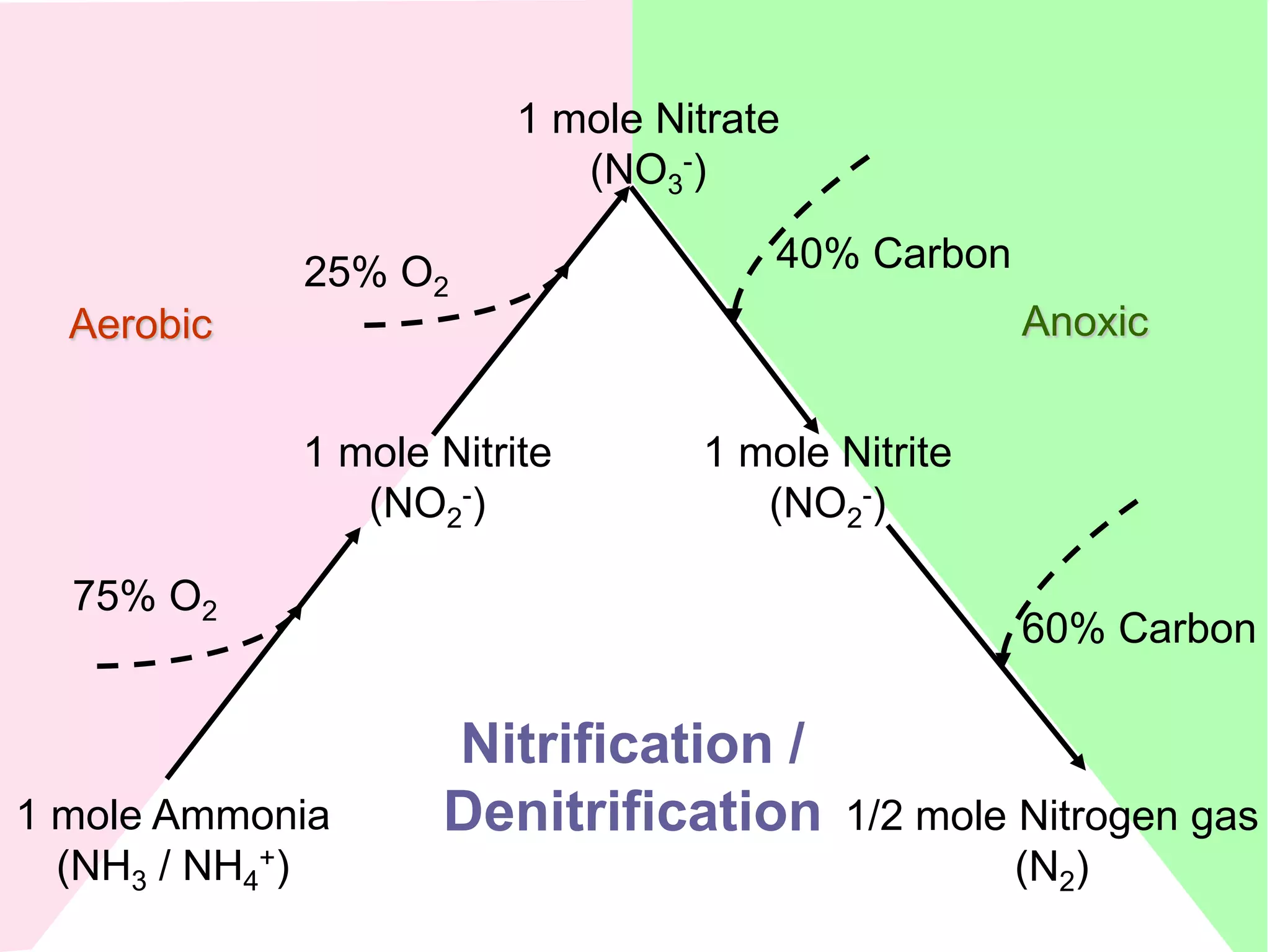

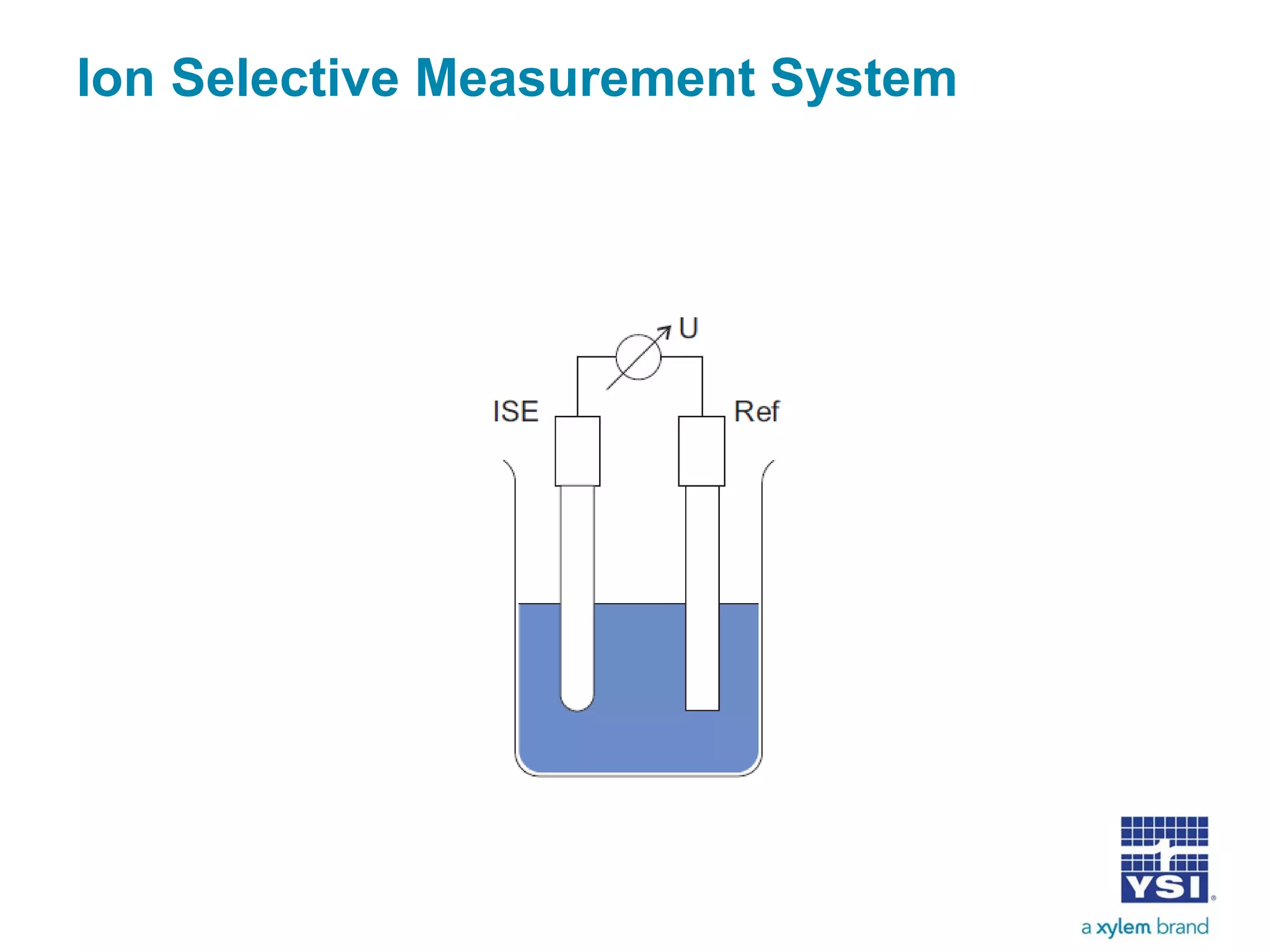

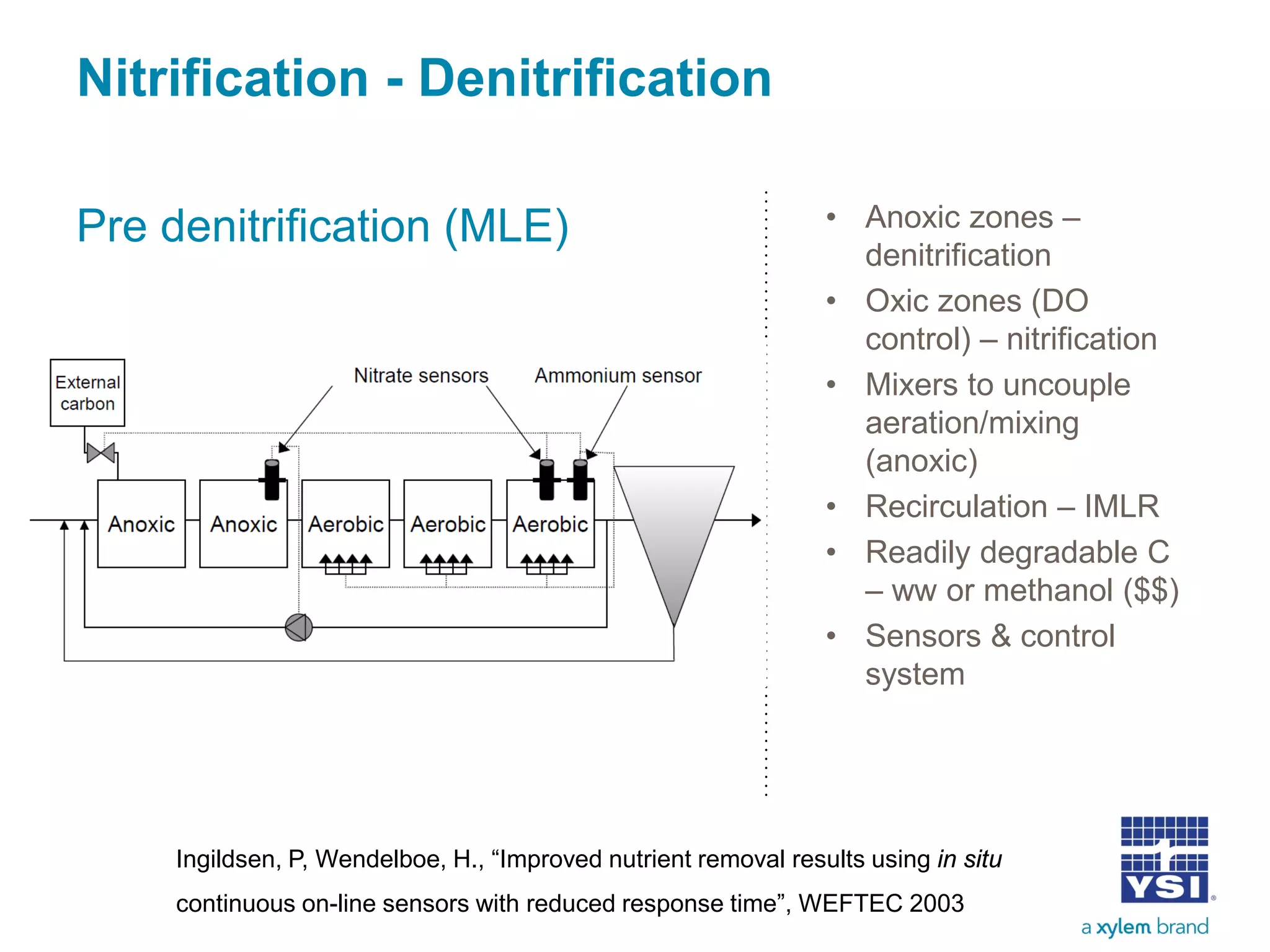

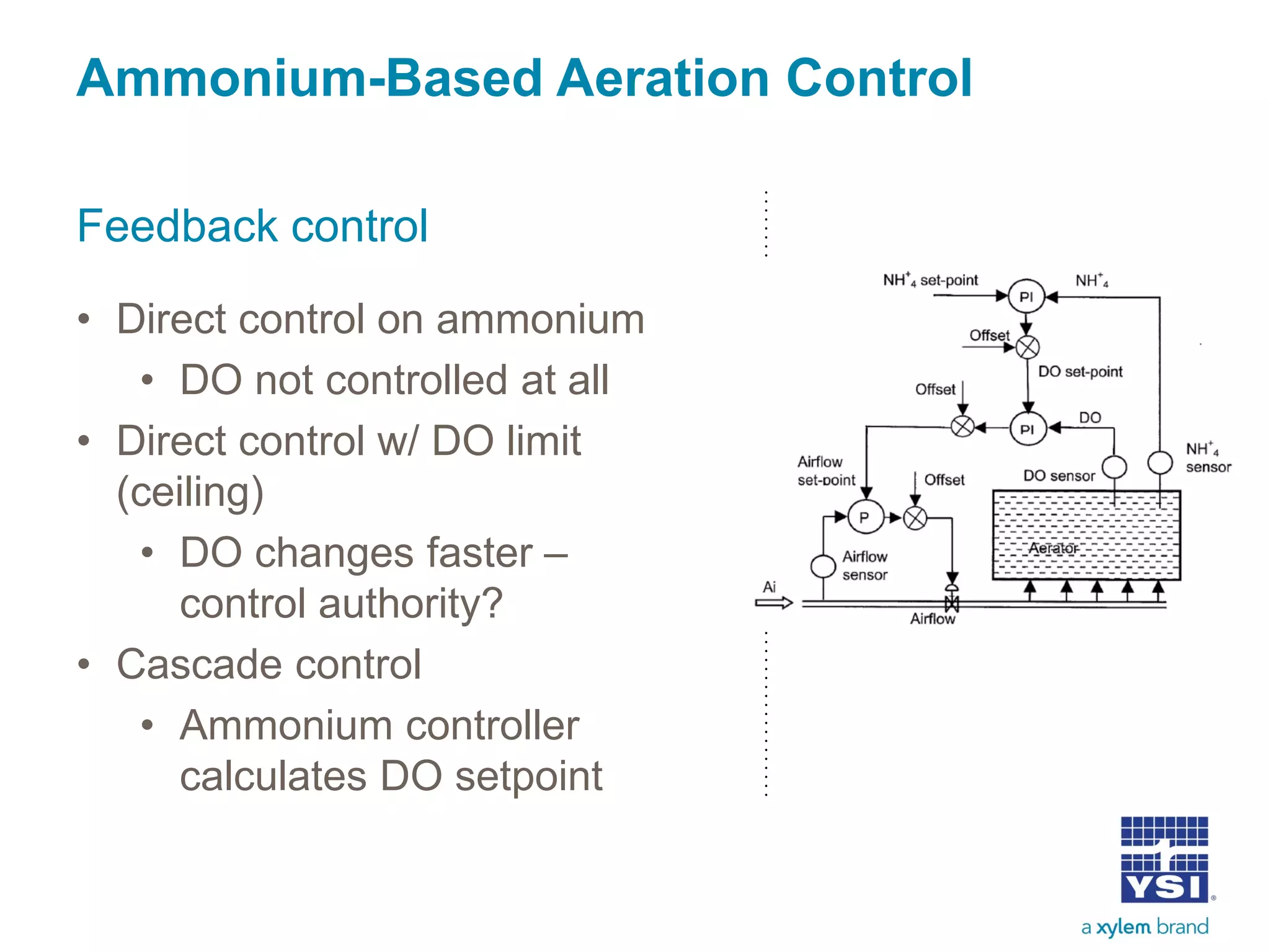

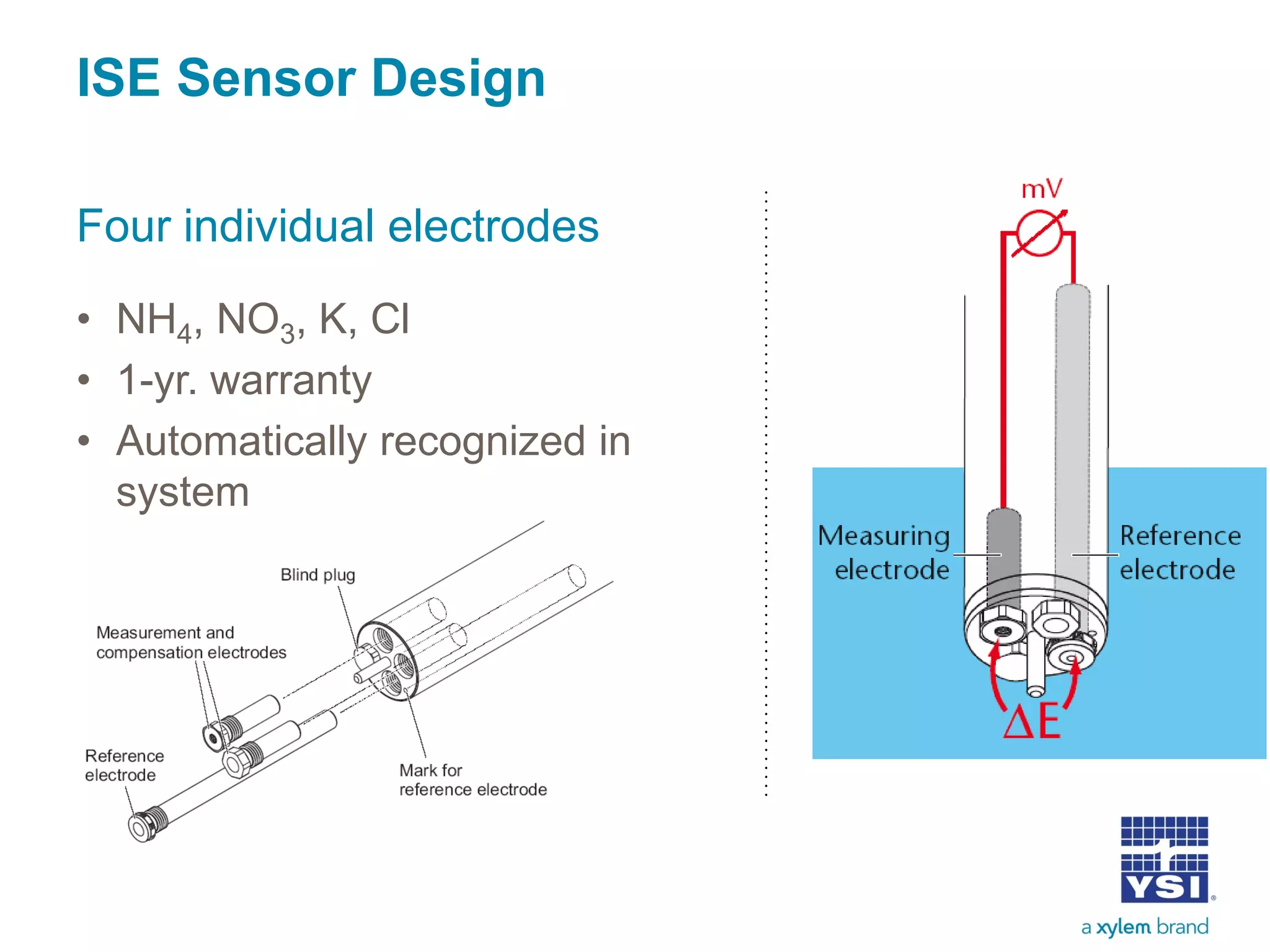

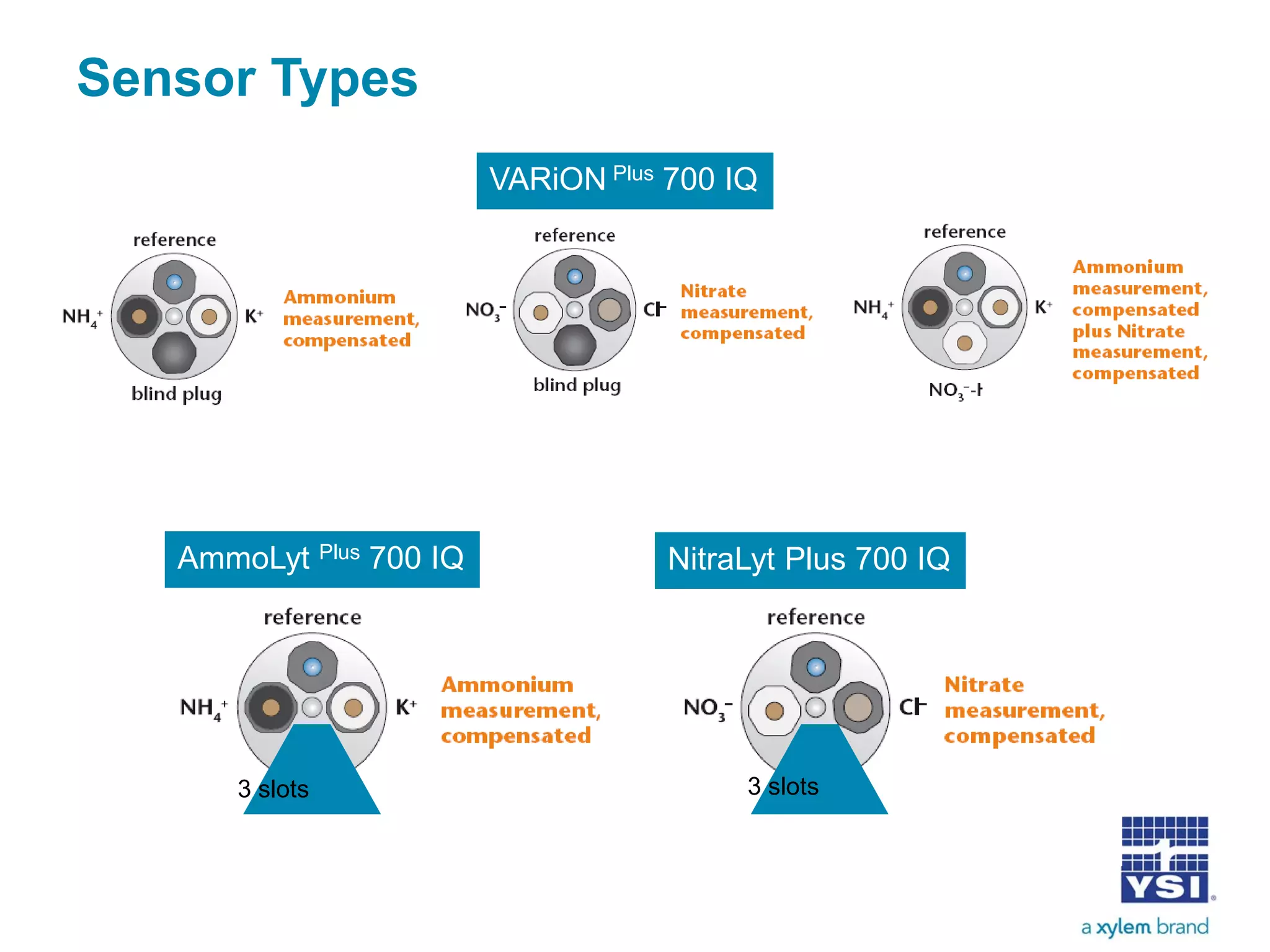

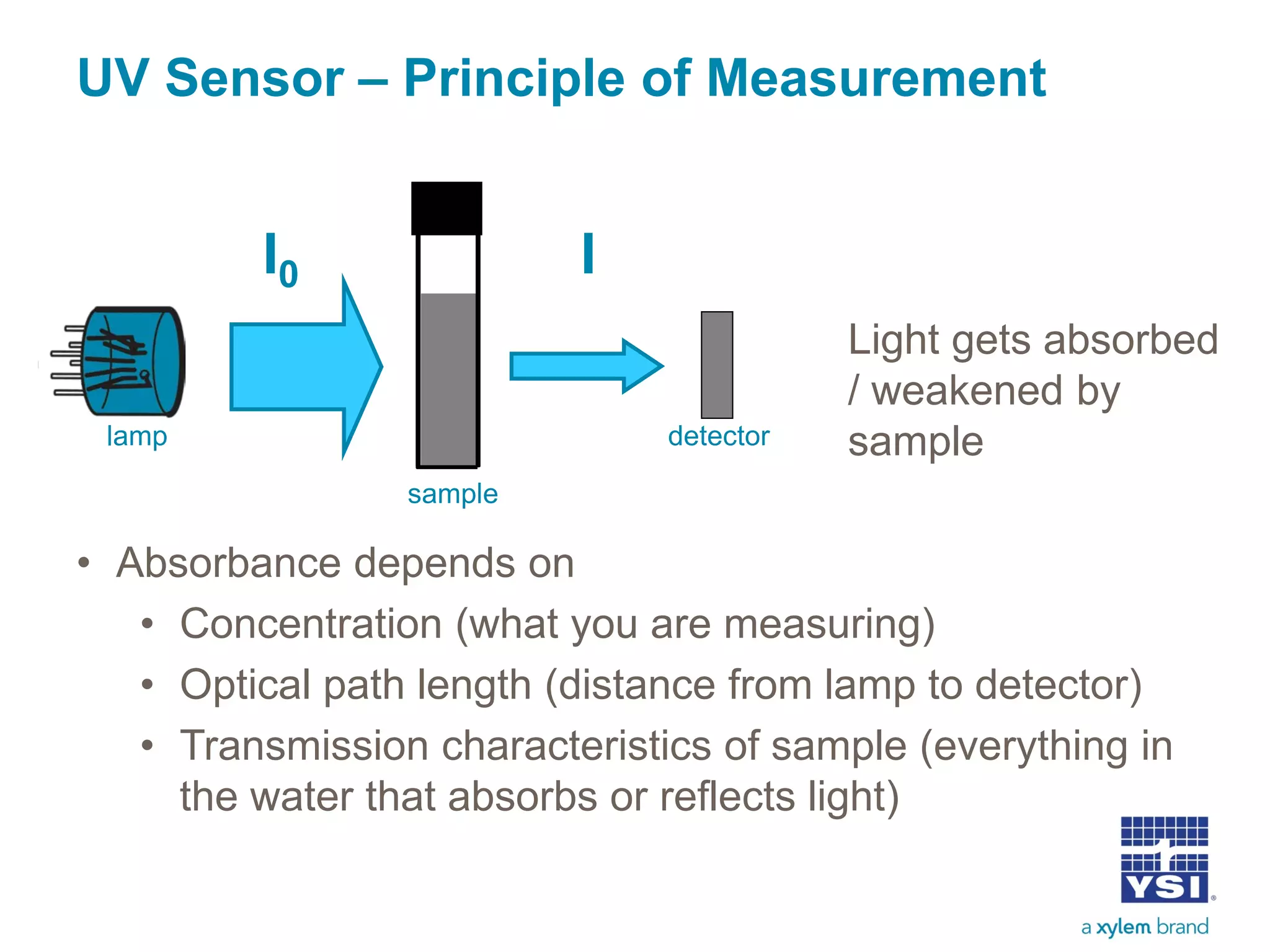

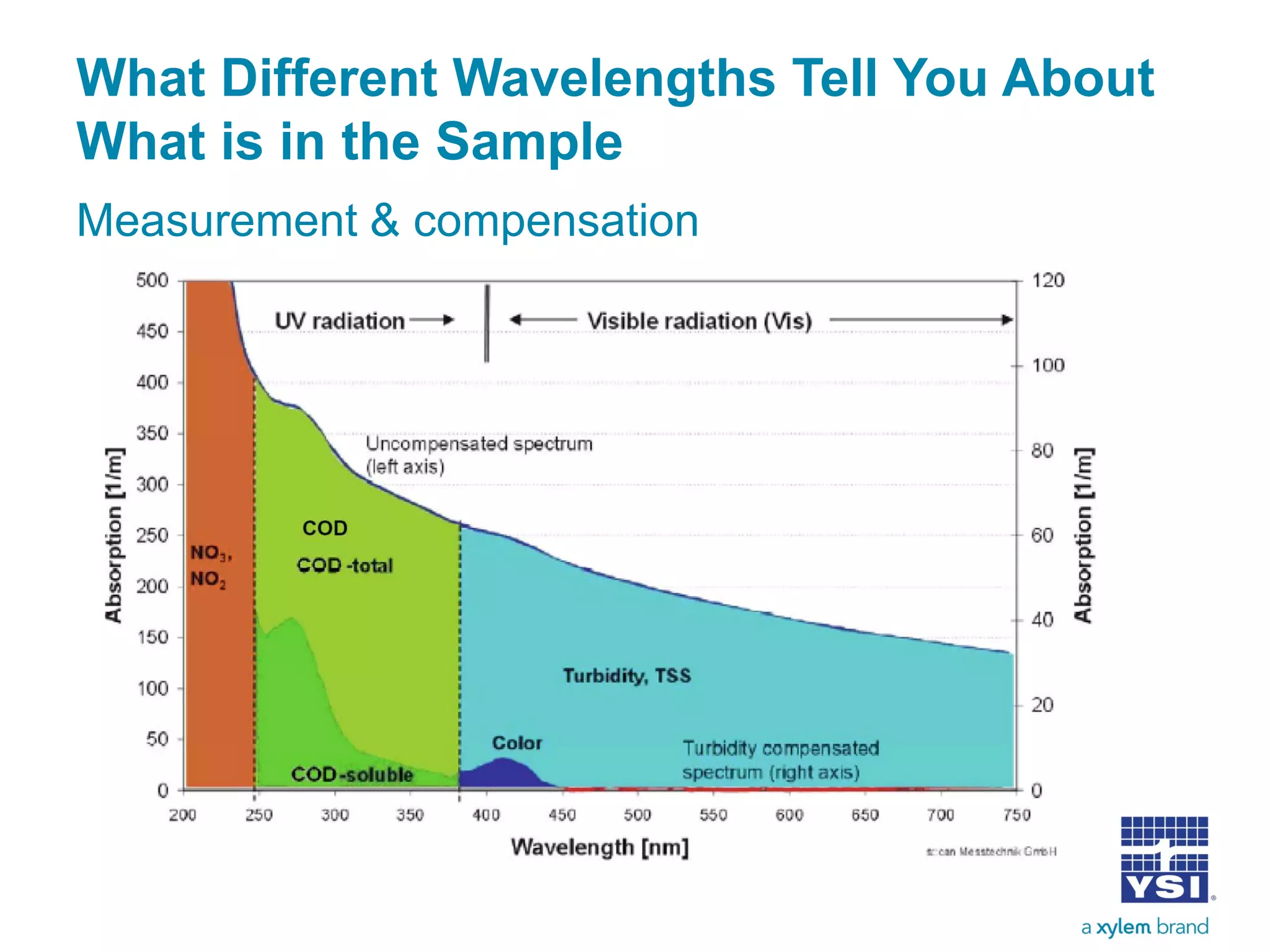

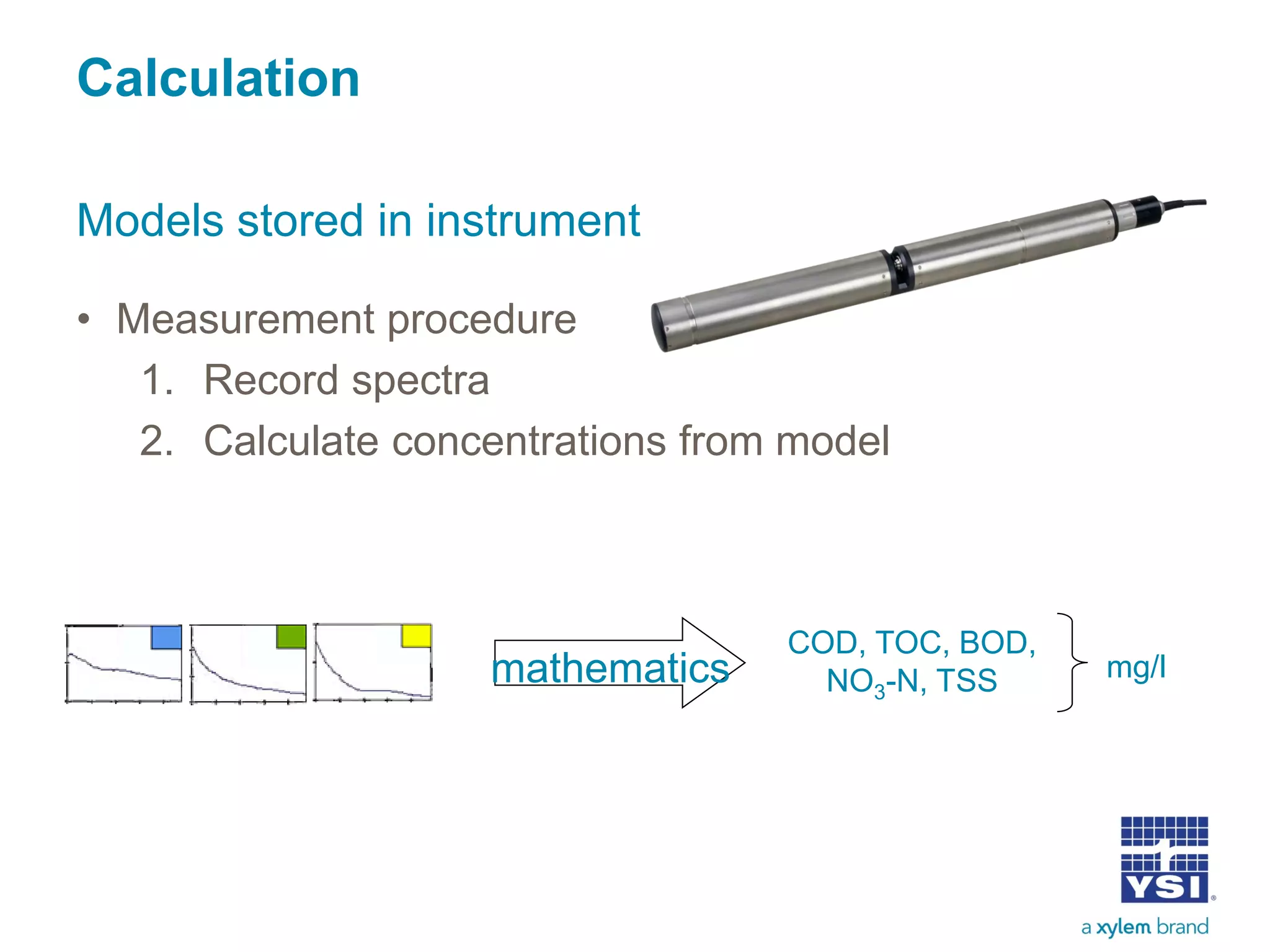

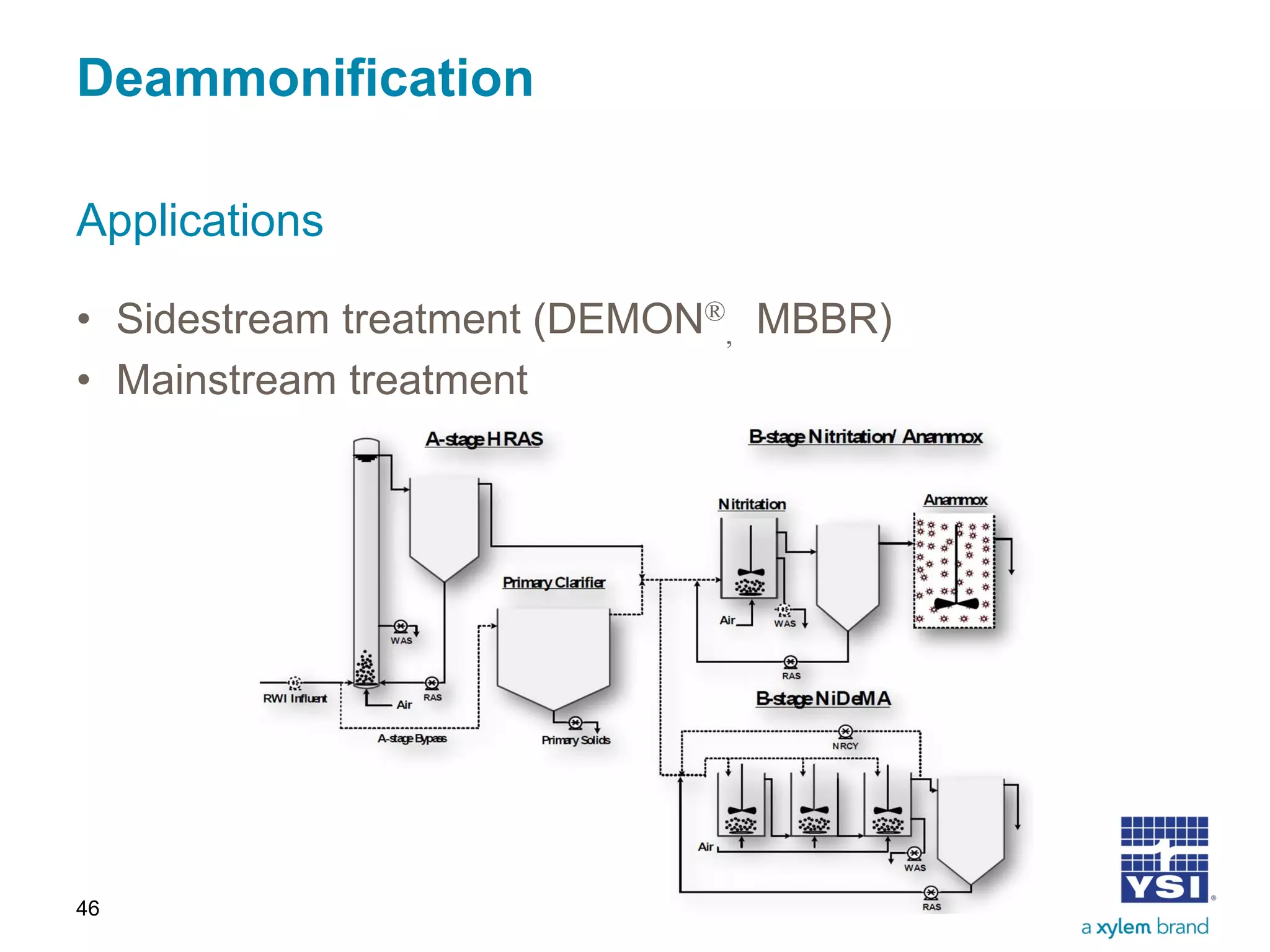

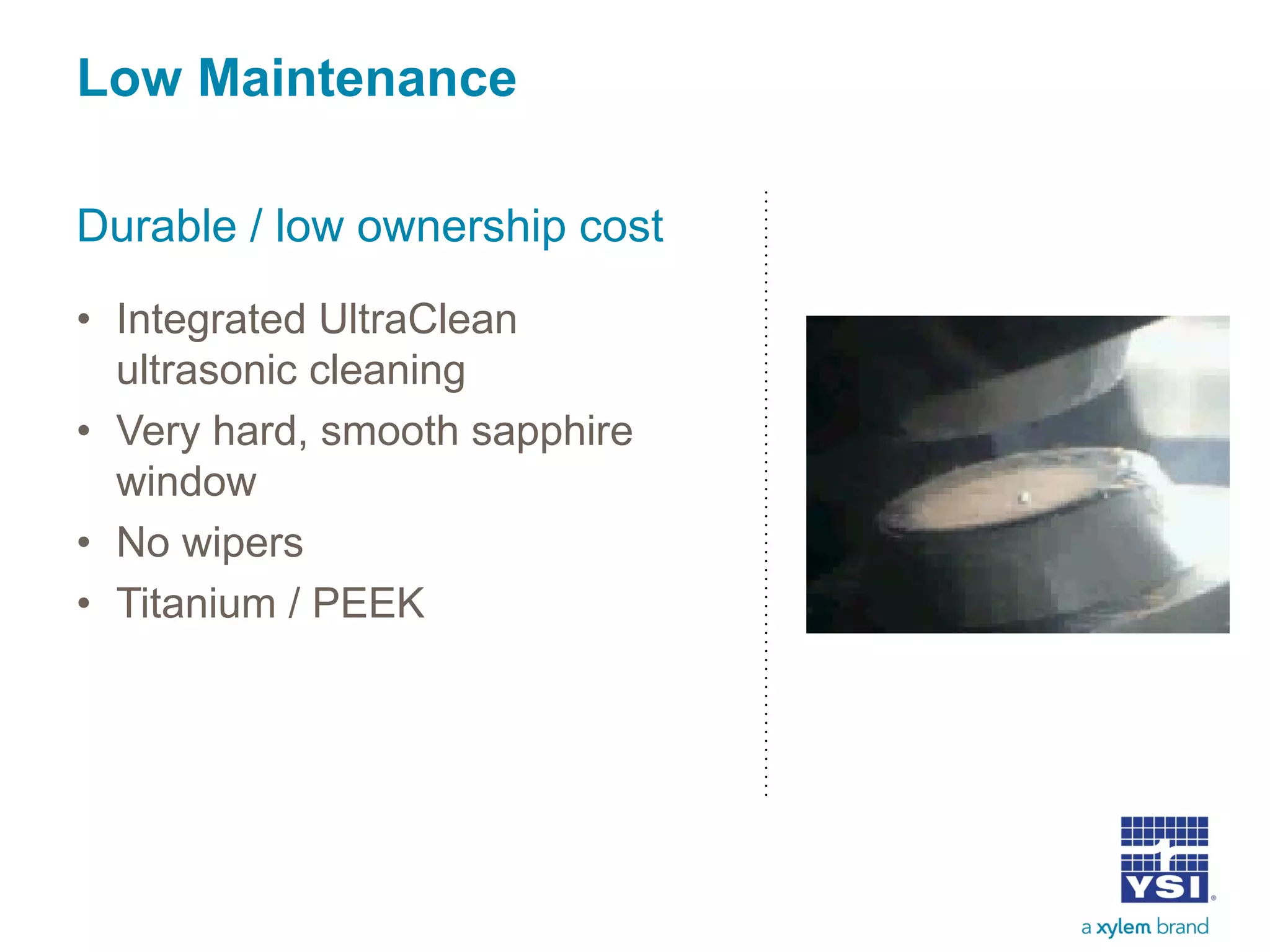

The document discusses advancements in online process monitoring and automation for water resource recovery facilities, focusing on new technologies such as solid-state in-situ sensors and multiparameter controllers. It highlights the importance of accurate measurements for dissolved oxygen, nitrogen, and total suspended solids while detailing various control strategies and sensor types for effective water treatment. Additionally, it mentions specific models and features of sensors designed to improve nutrient removal and recovery processes.

![Difference Between UV and UV-VIS Sensors

Measurement of NO2 and NO3

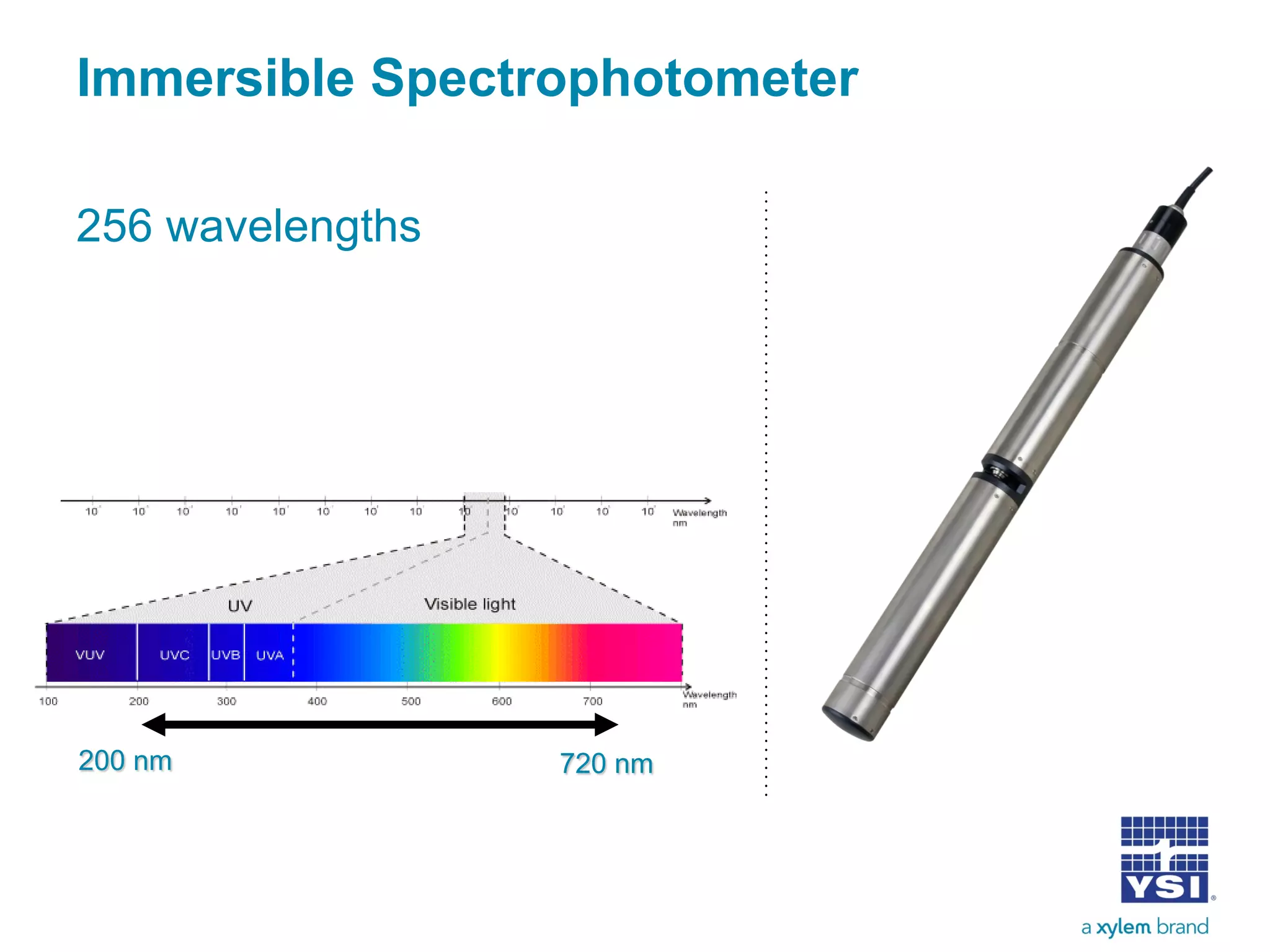

• 256 wavelengths measured

• 200 – 390 nm

• 0.74 nm resolution

wavelength [nm]](https://image.slidesharecdn.com/ysiiqsensornetprocessmonitoringandautomationofwrrfs-140424083459-phpapp02/75/Process-Monitoring-and-Automation-of-Water-Resource-Recovery-Facilities-IQ-SensorNet-YSI-44-2048.jpg)

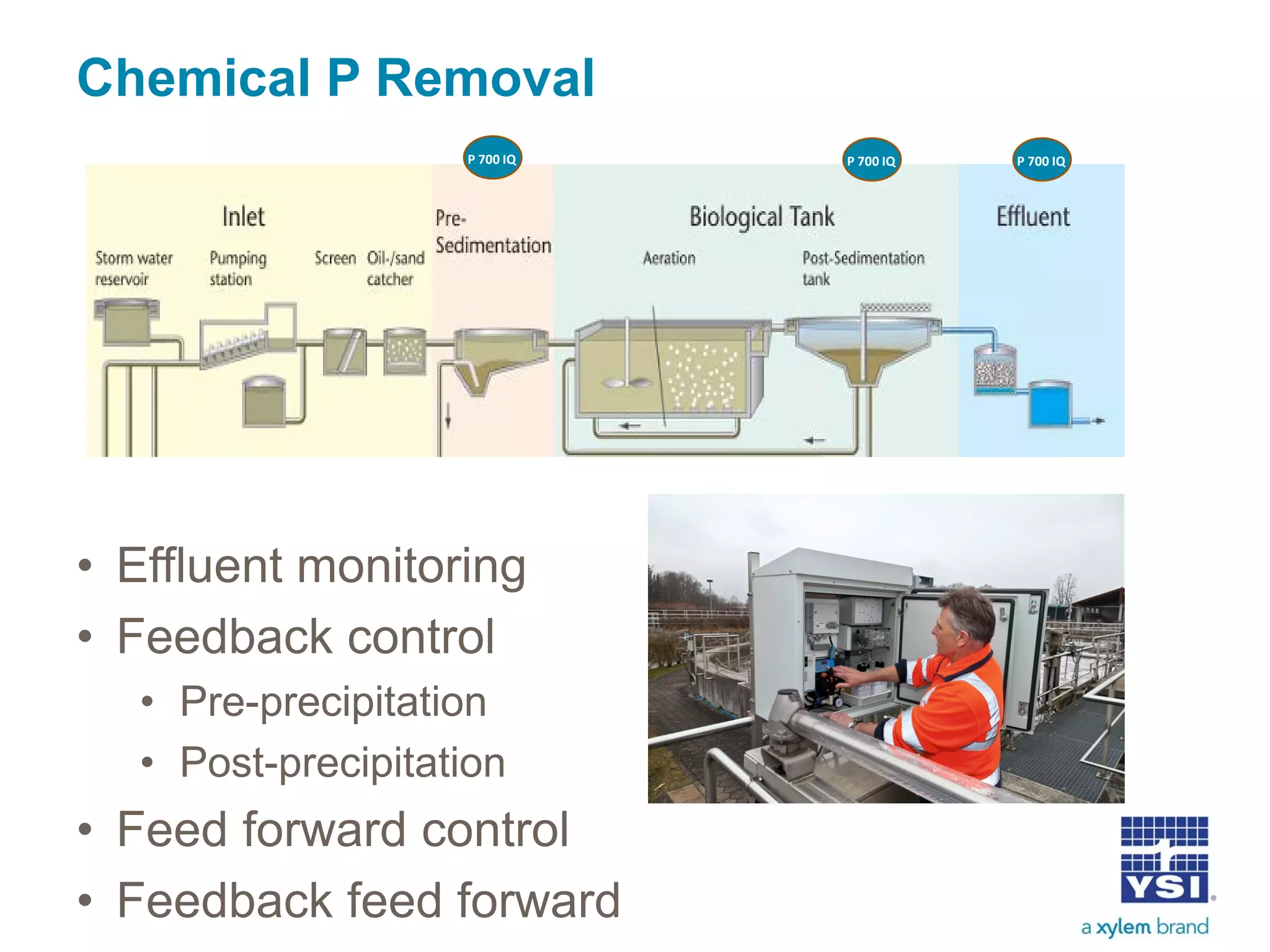

![Application Example Chemical Dosing

Flocculating

agent

Phosphate

[mg/l]

time

Use of P700 IQ for regulation of

flocculating agent dosage](https://image.slidesharecdn.com/ysiiqsensornetprocessmonitoringandautomationofwrrfs-140424083459-phpapp02/75/Process-Monitoring-and-Automation-of-Water-Resource-Recovery-Facilities-IQ-SensorNet-YSI-54-2048.jpg)