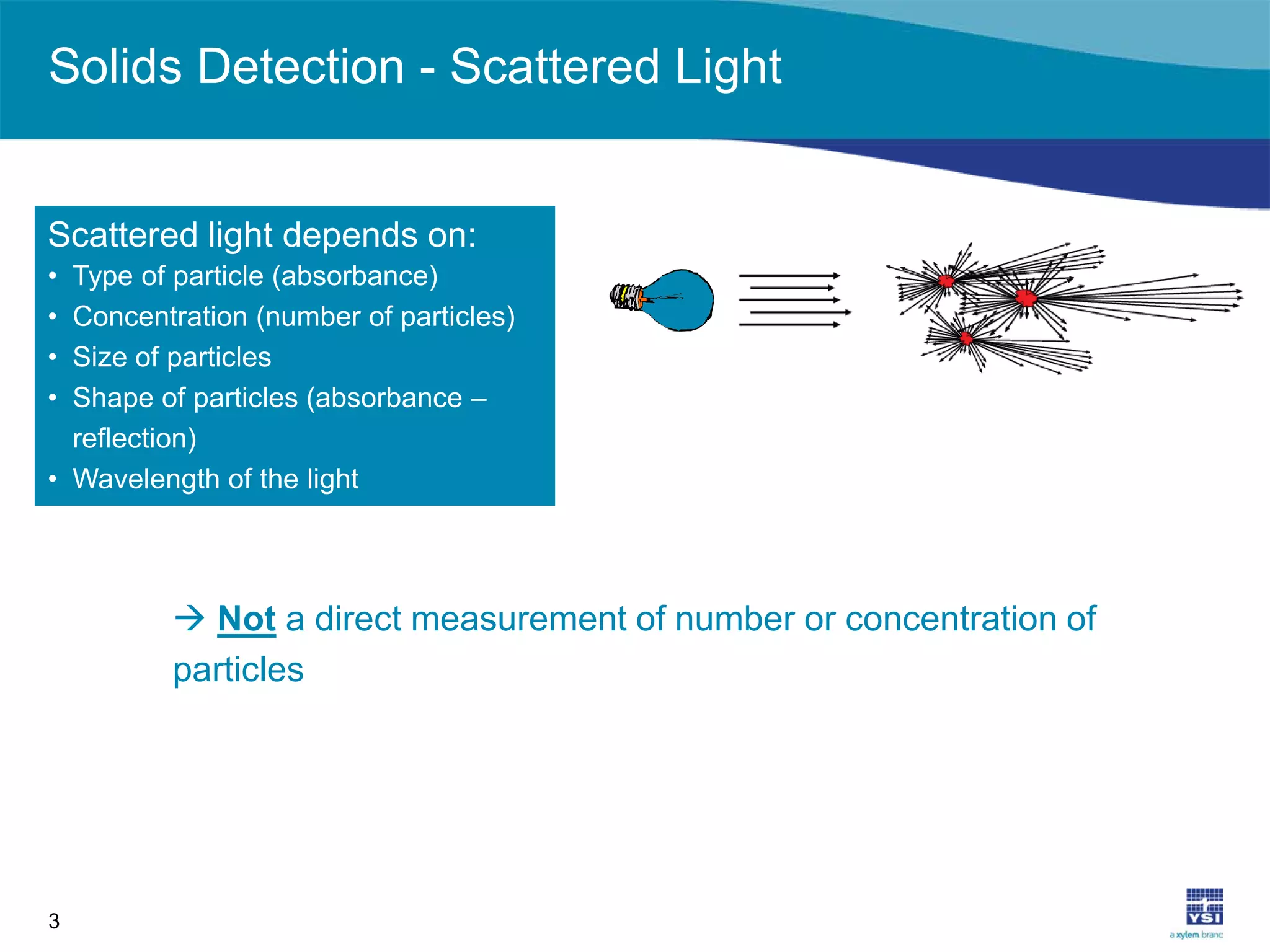

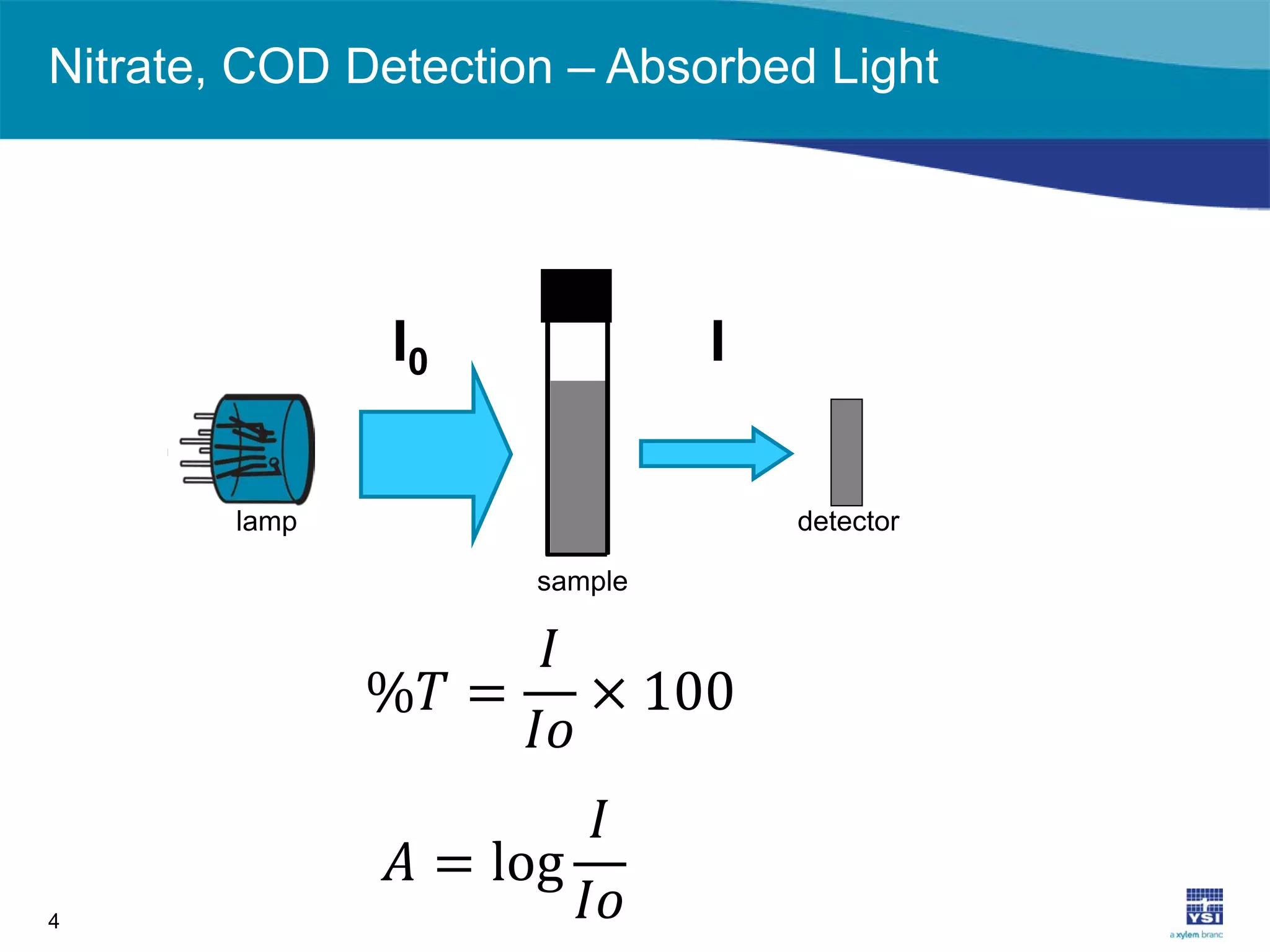

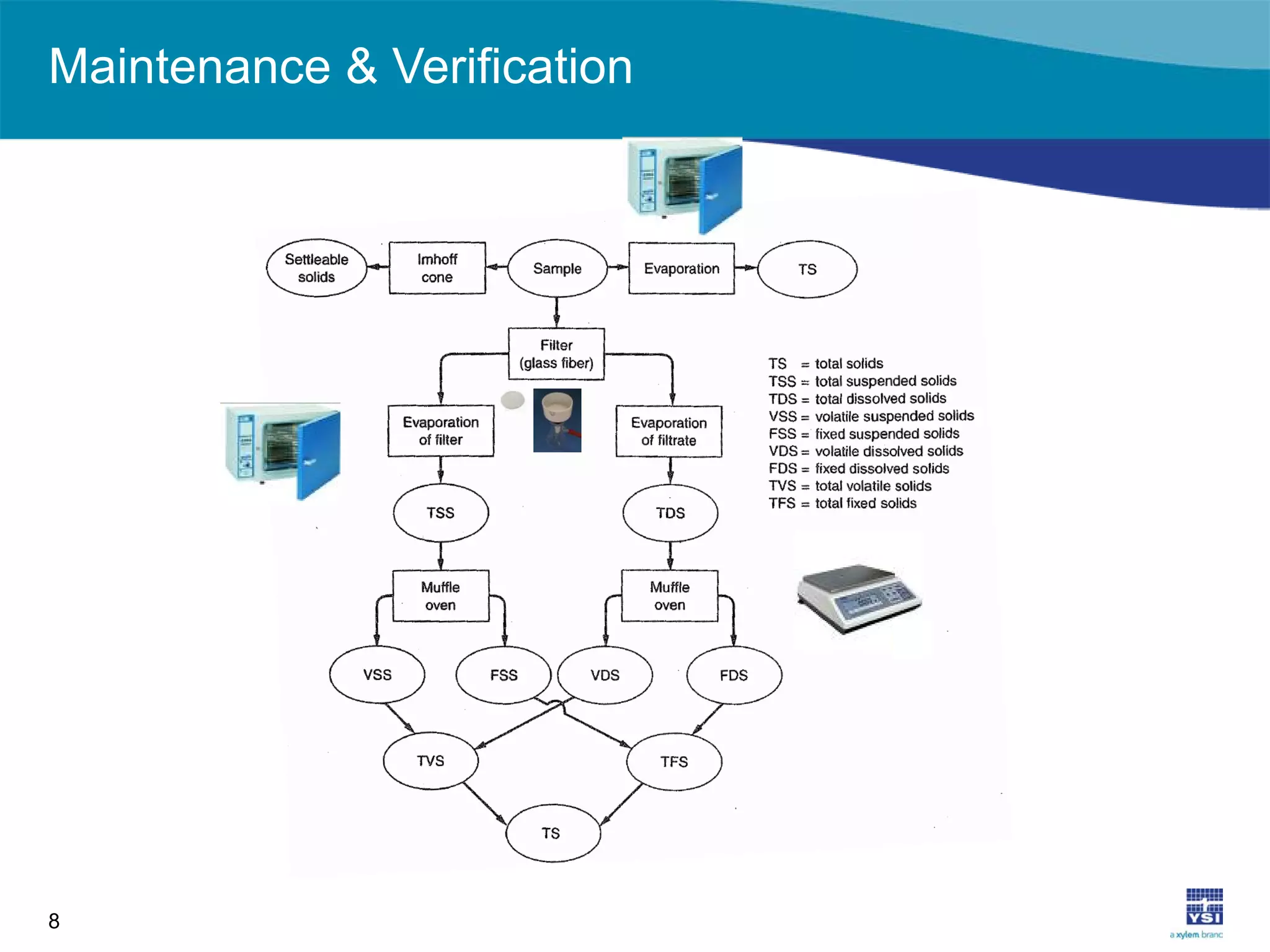

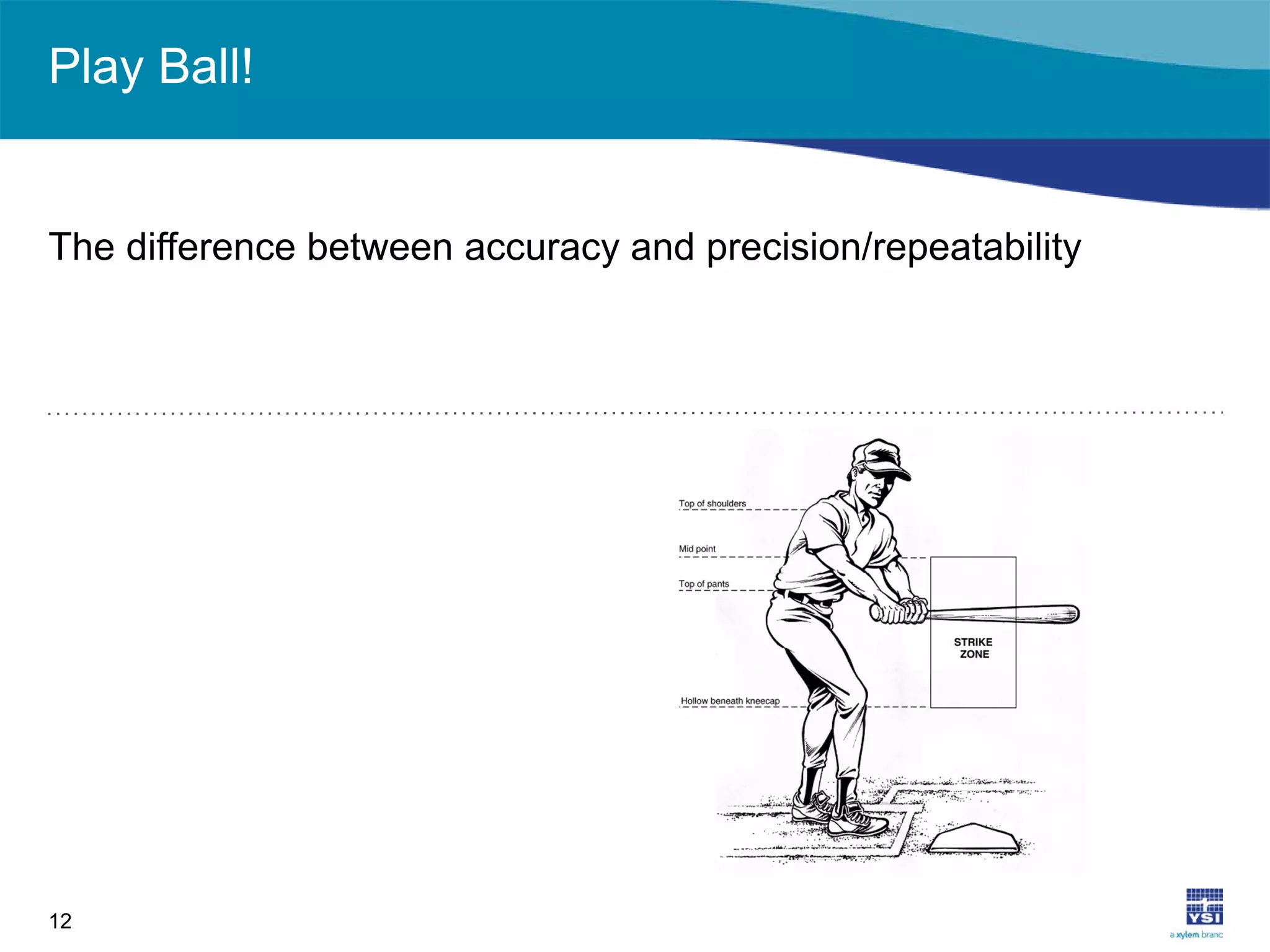

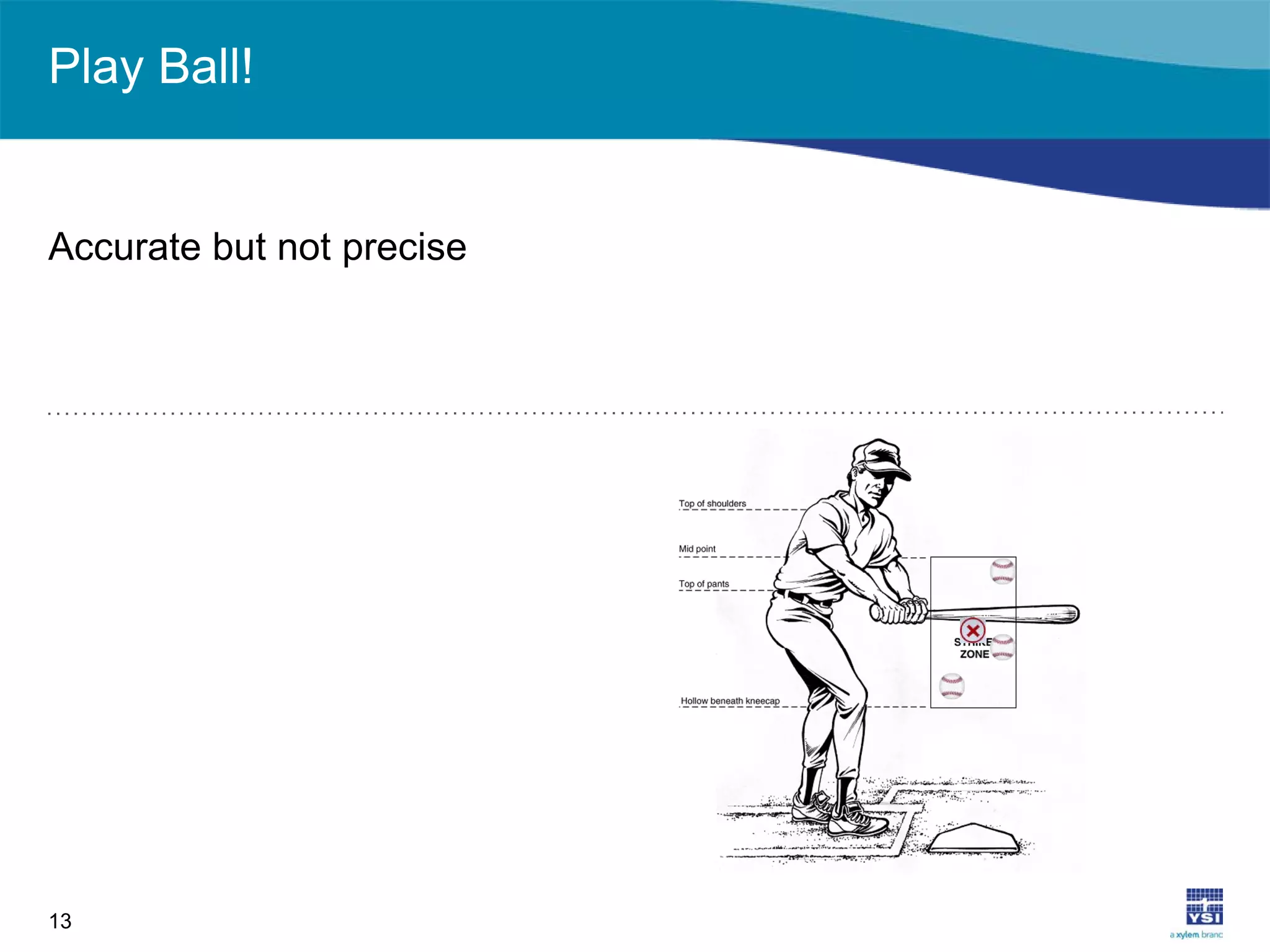

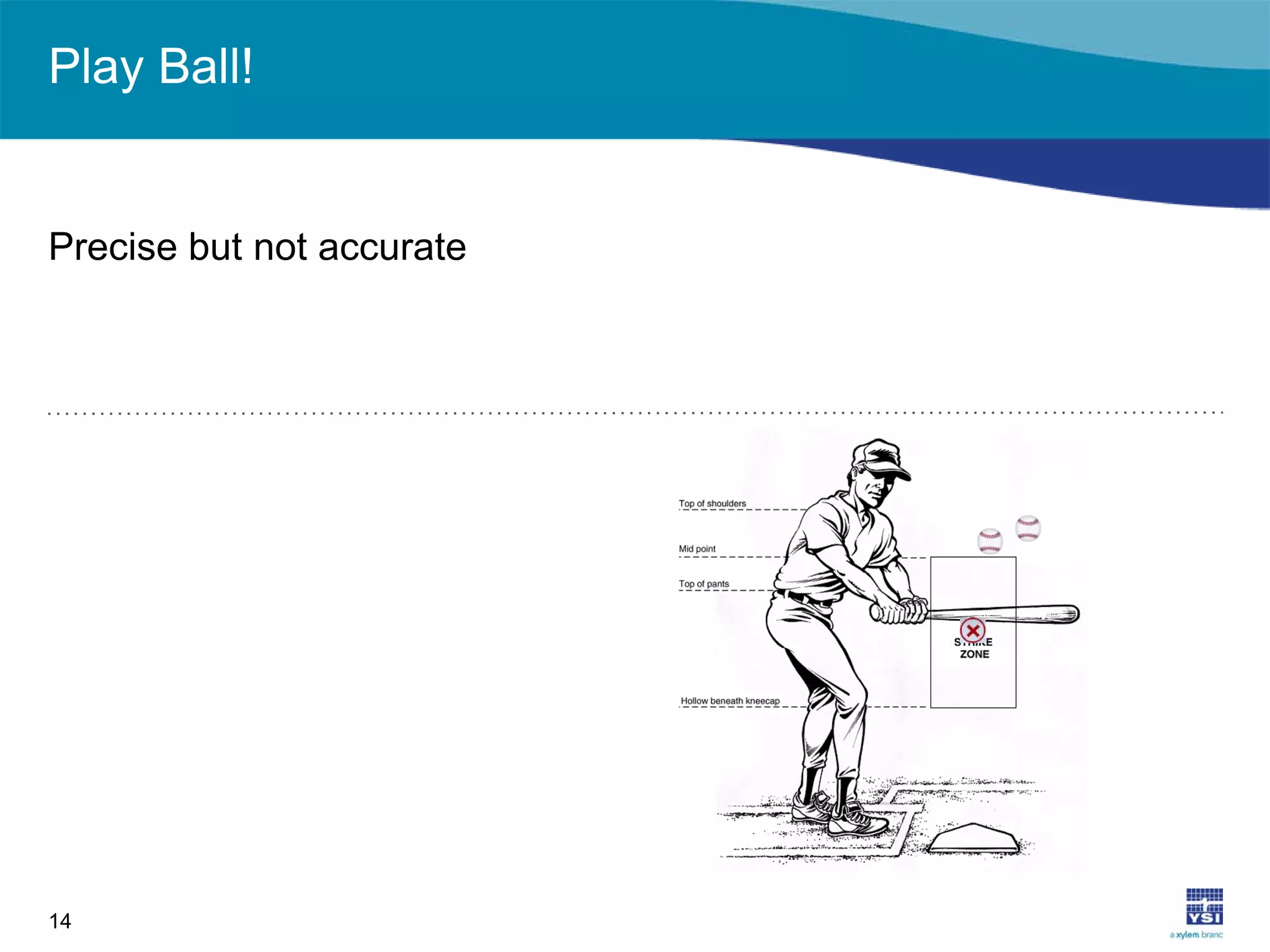

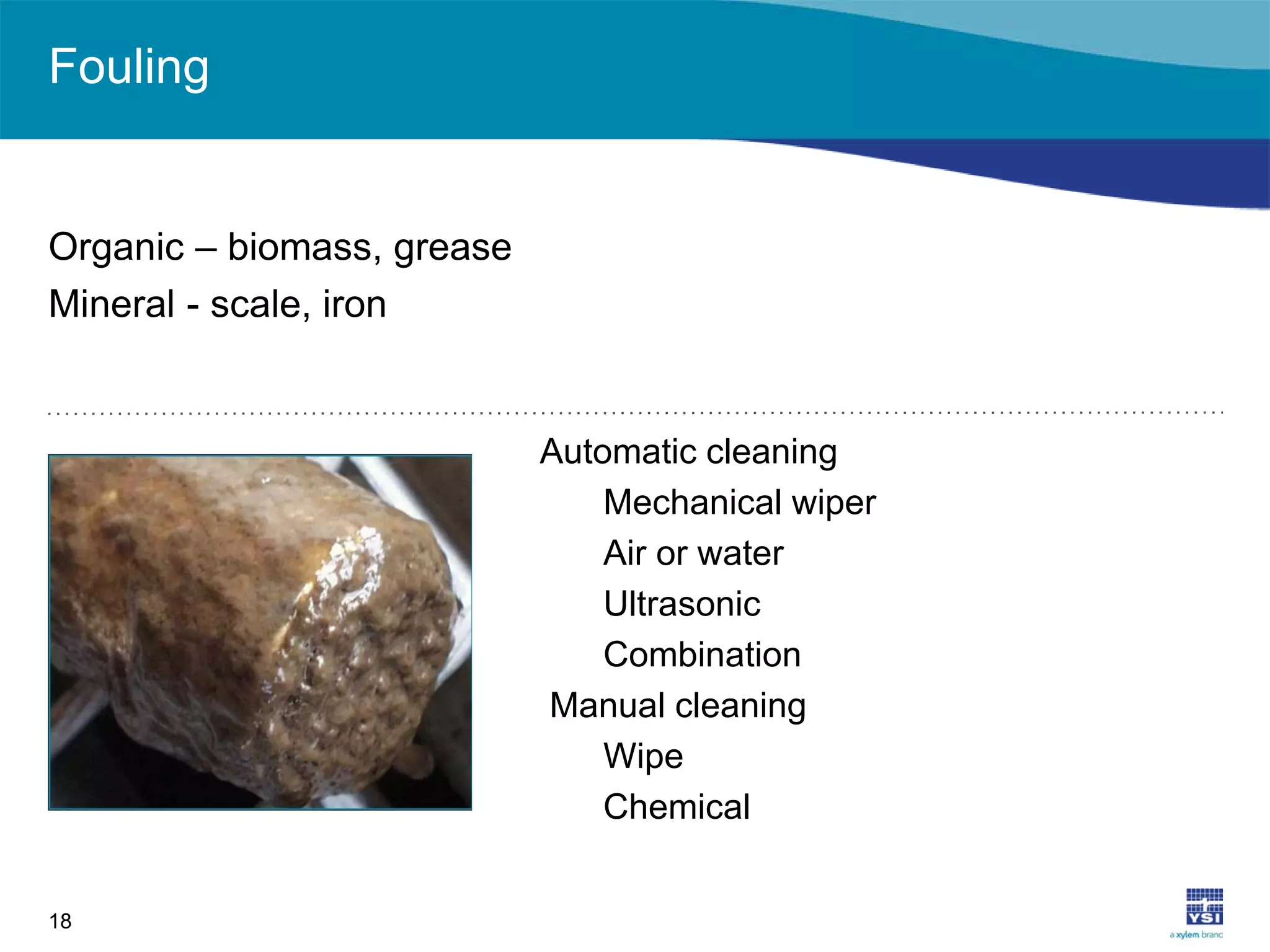

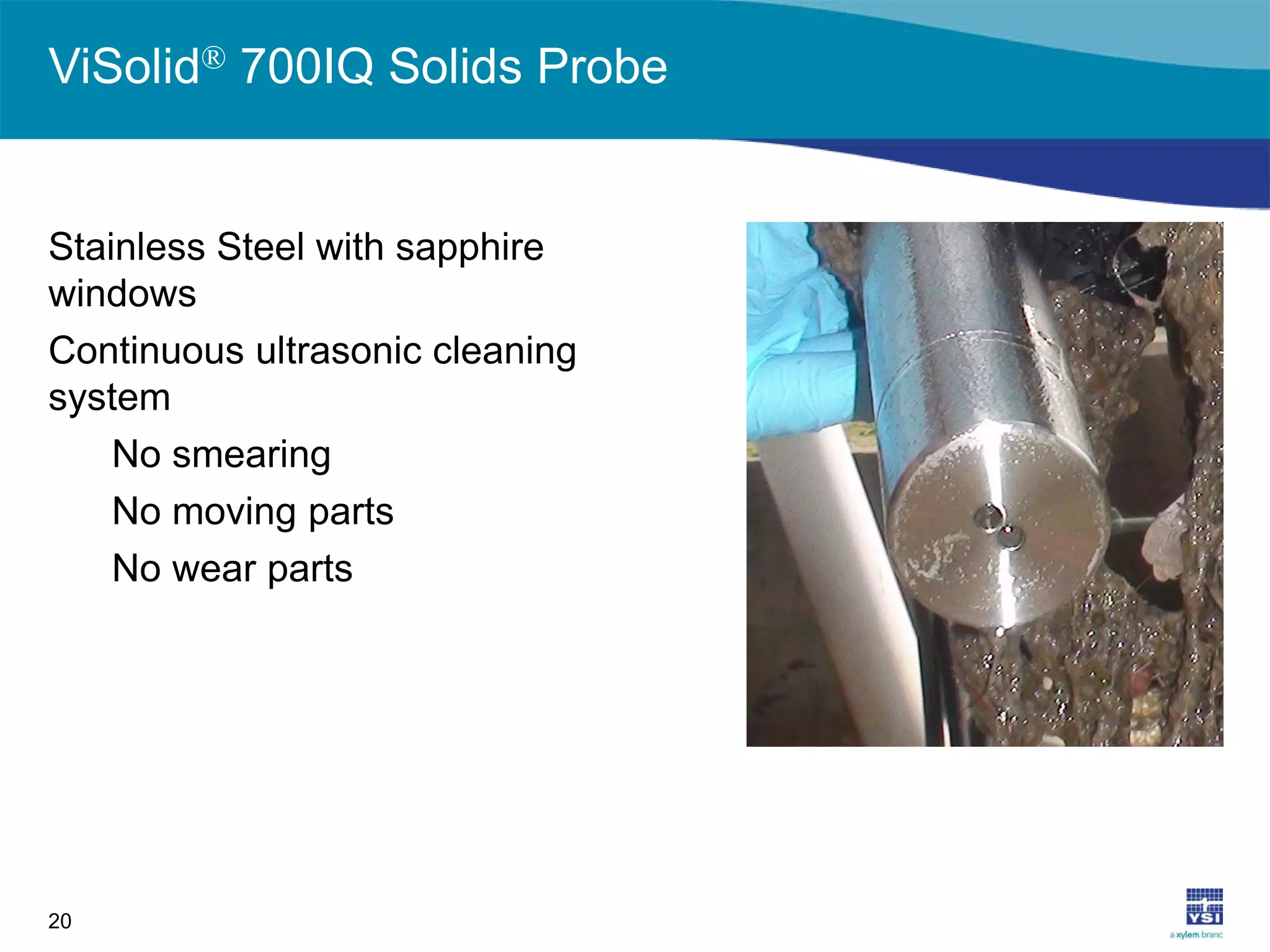

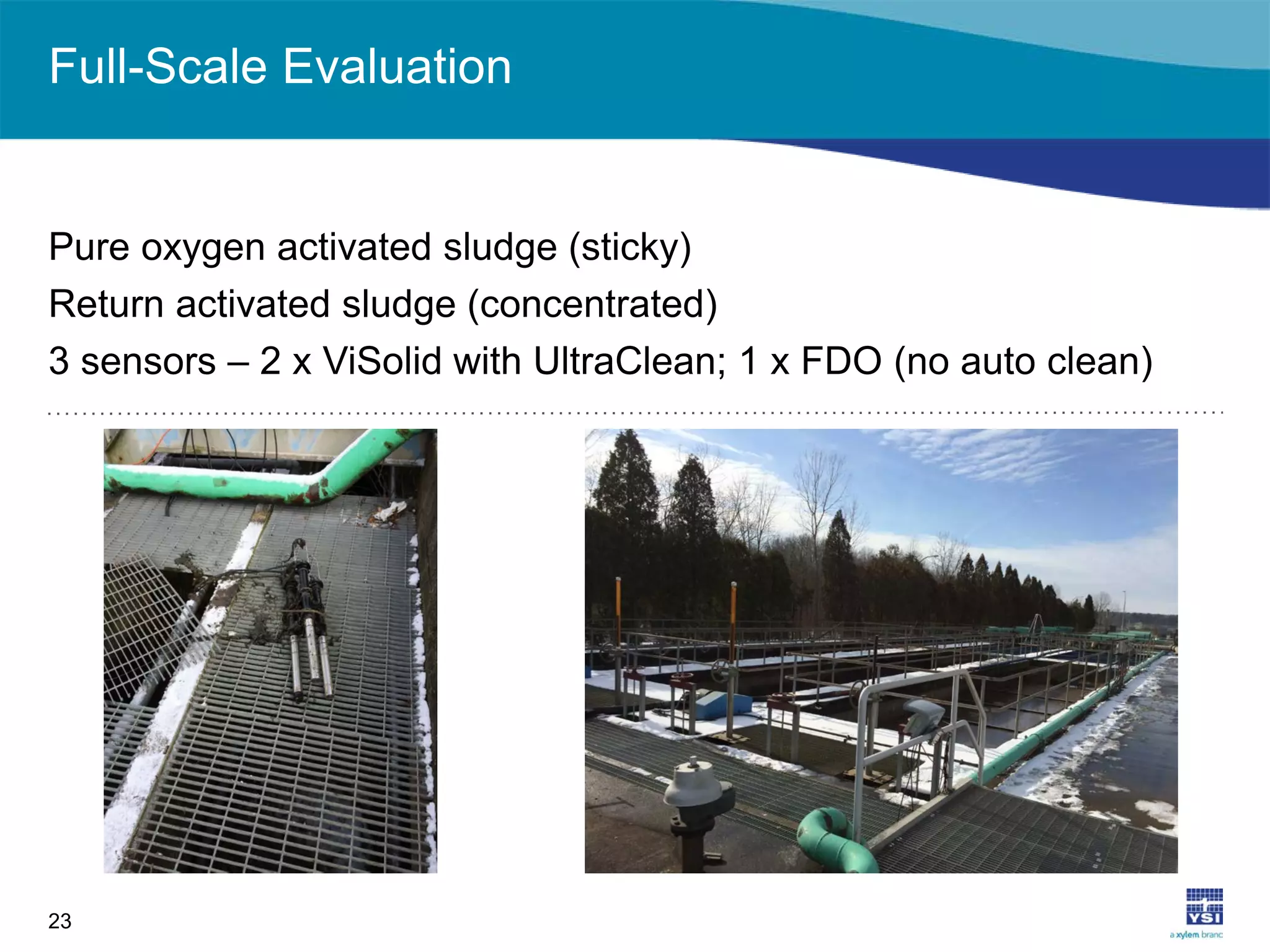

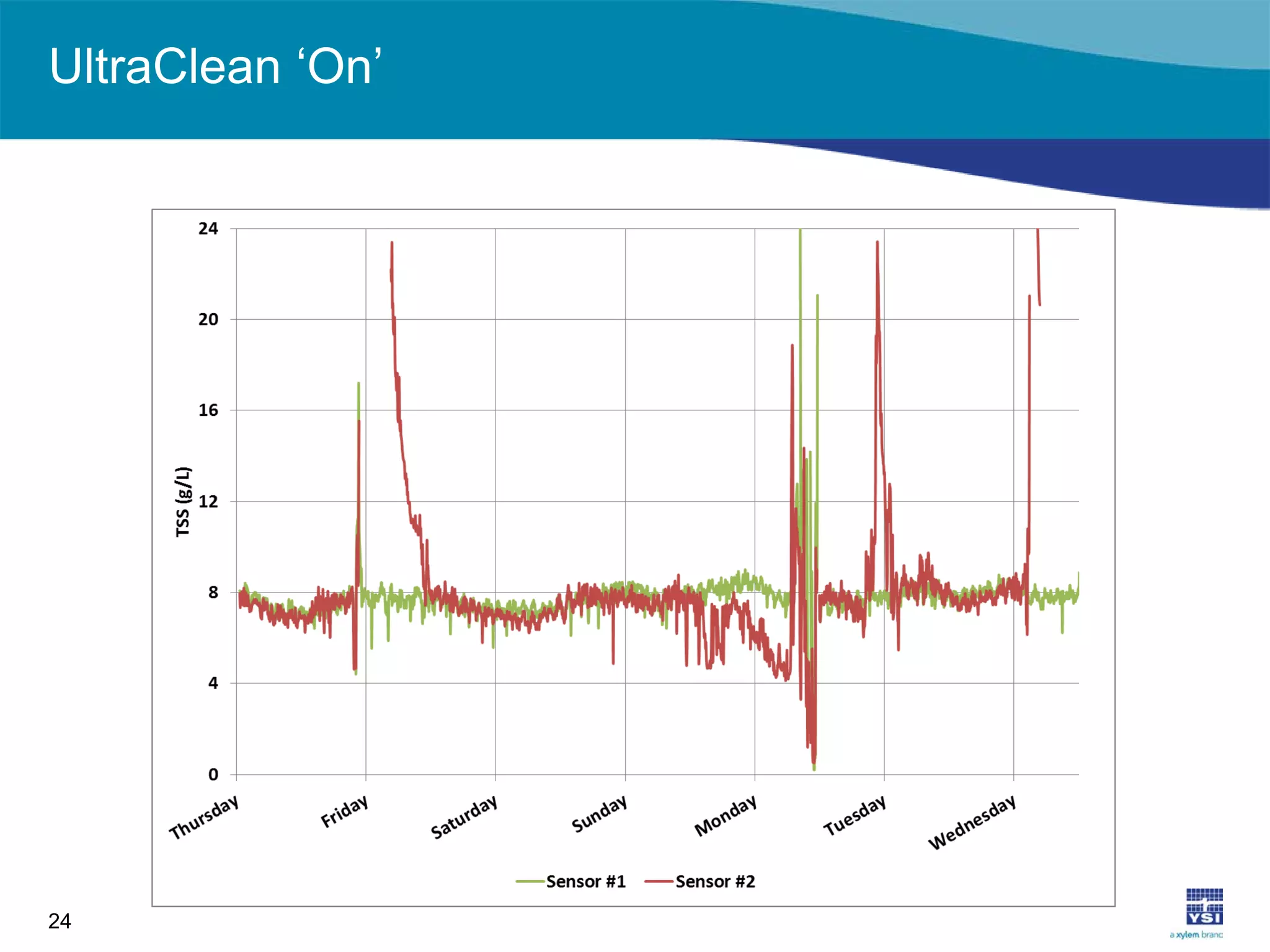

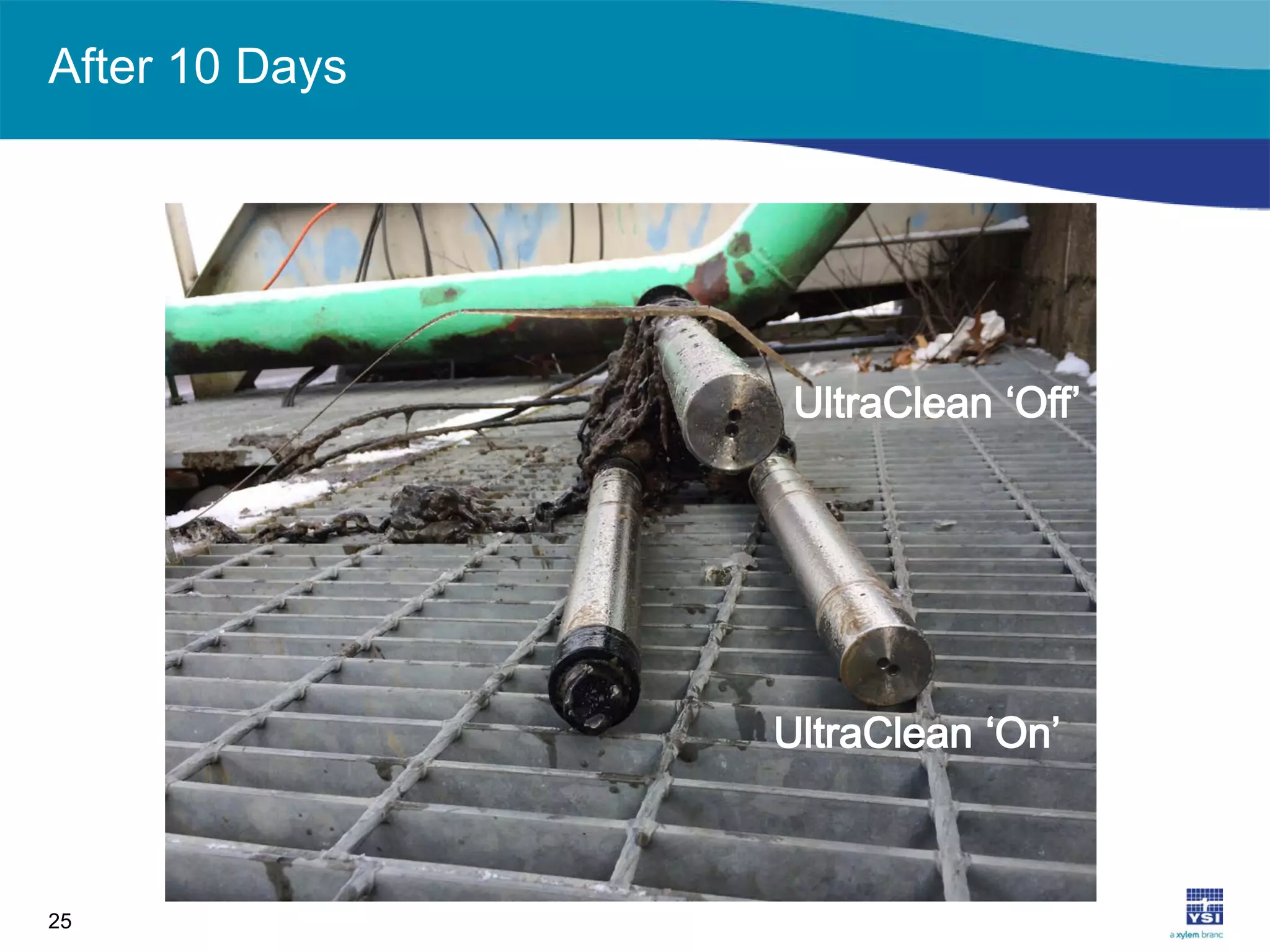

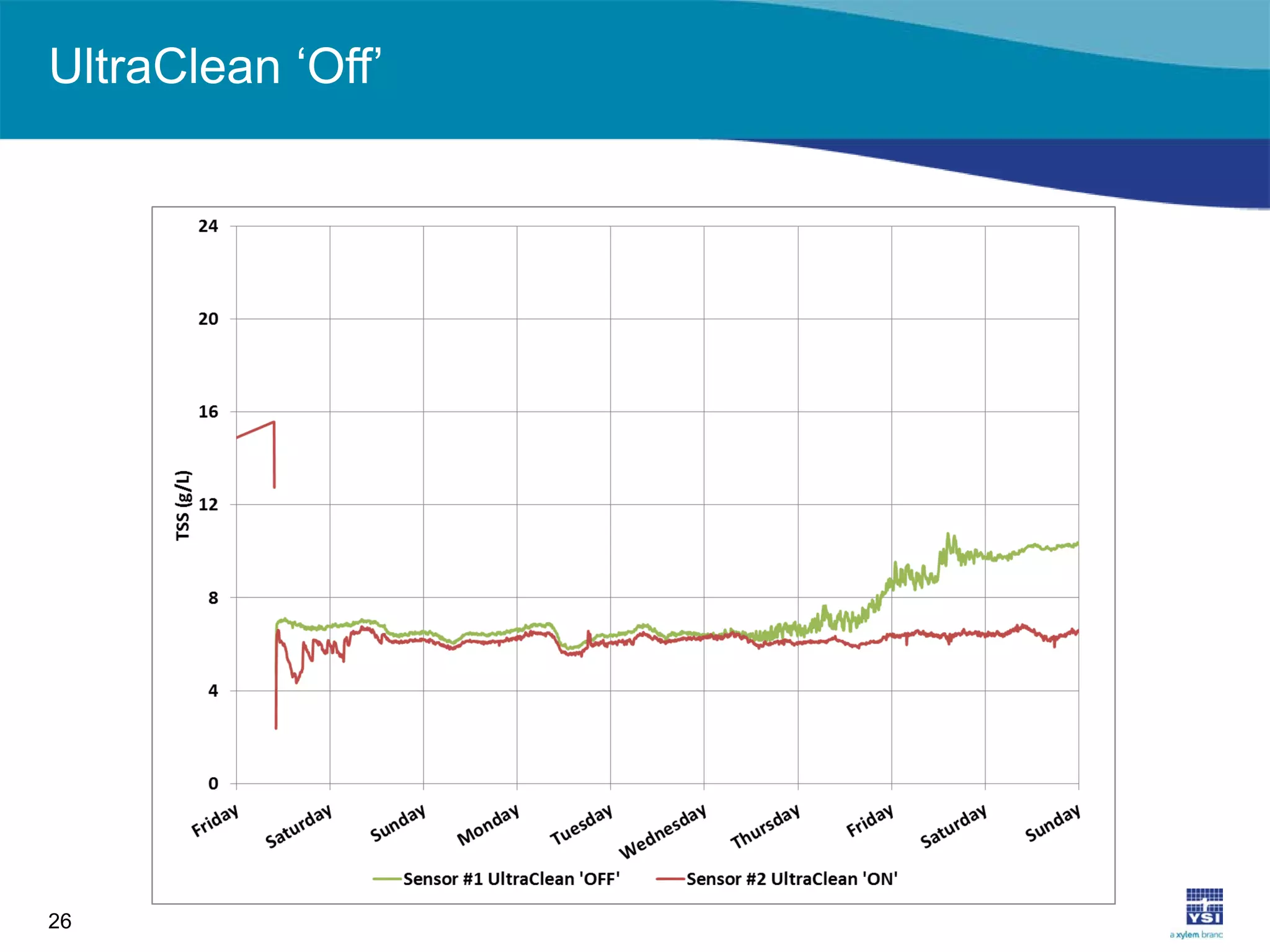

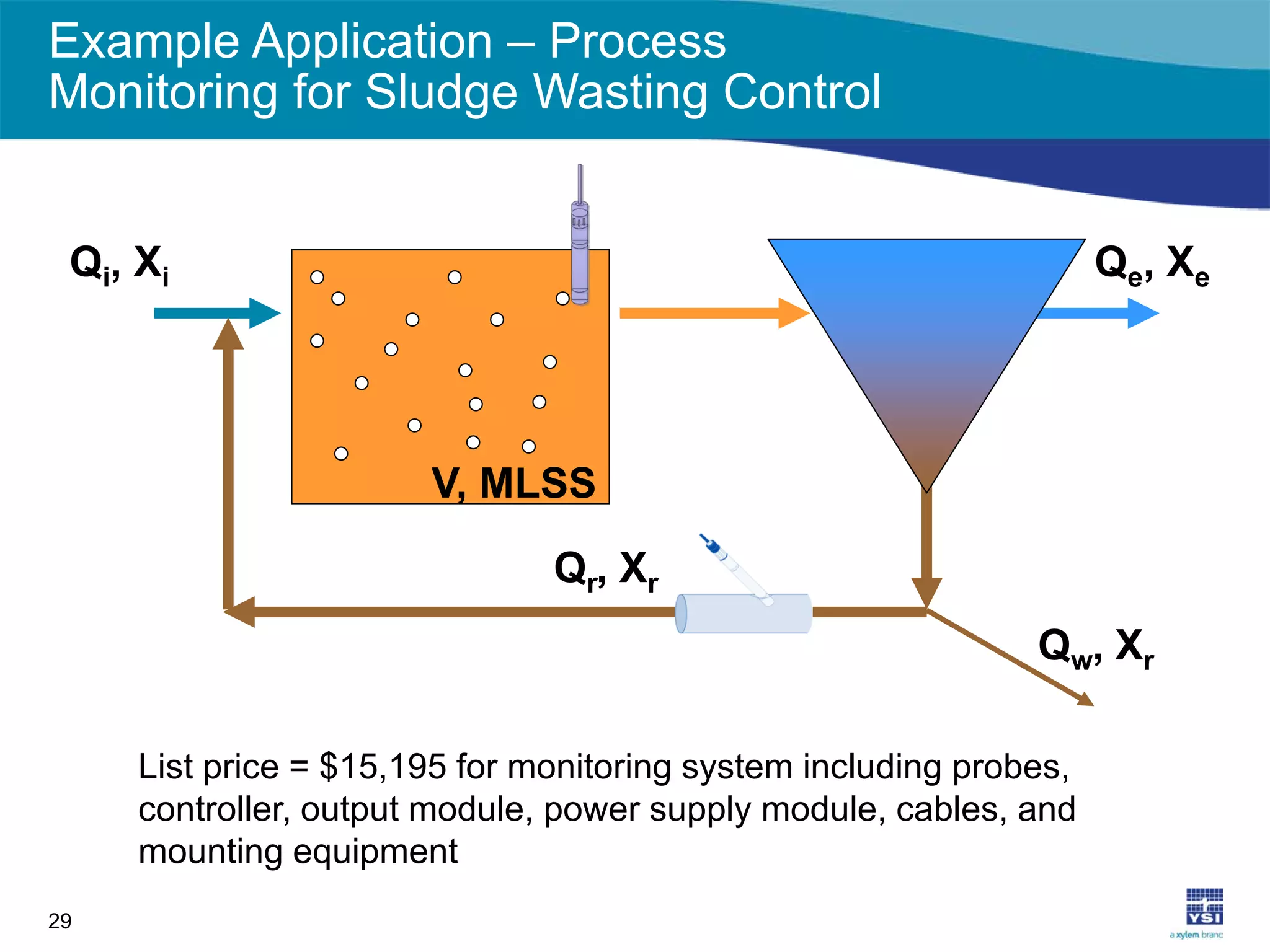

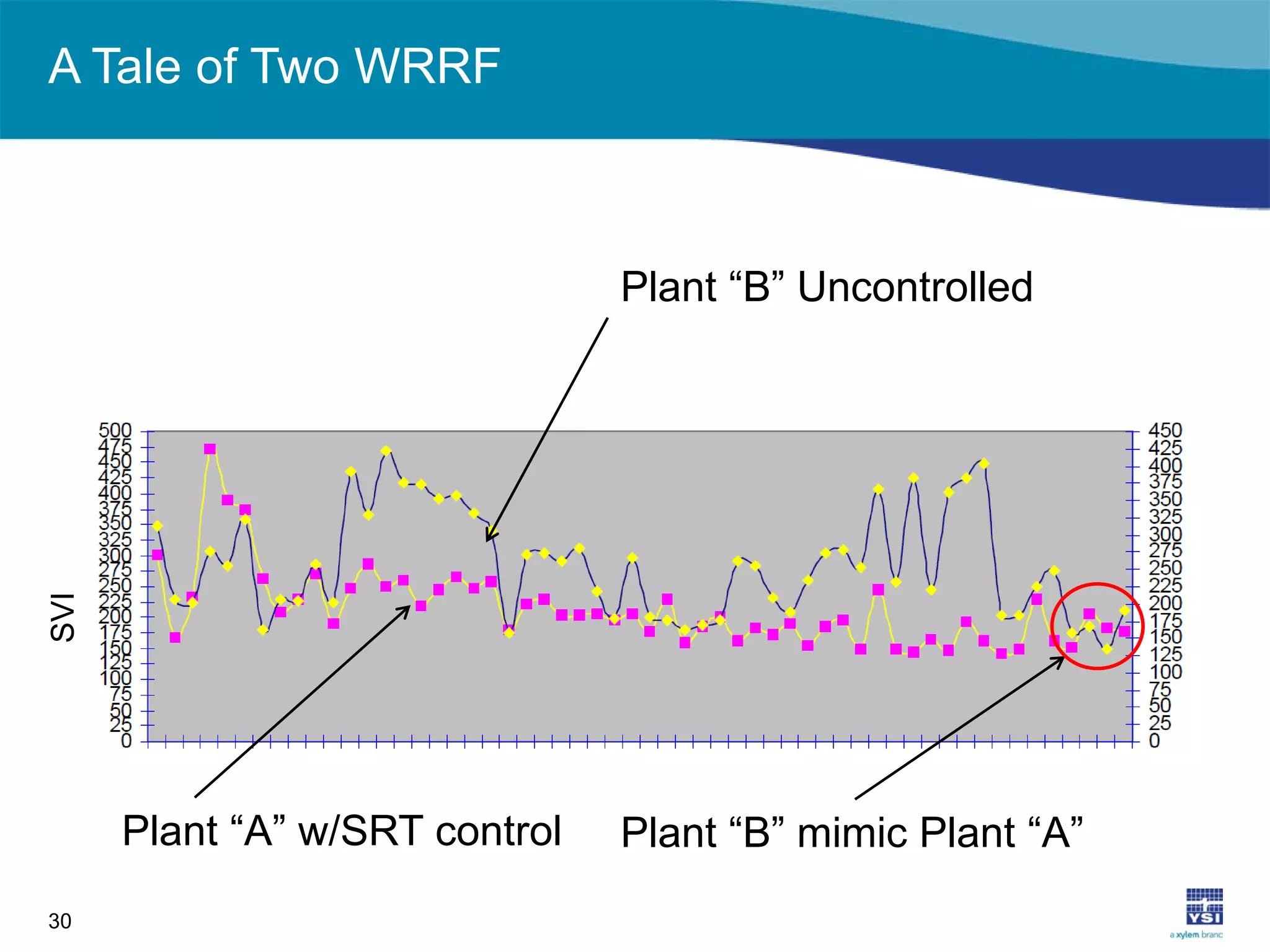

The document discusses the operation, maintenance, and fouling prevention of online wastewater sensors used in process monitoring. It emphasizes the importance of keeping sensors clean and highlights the benefits of the iqsn ultraclean technology in extending maintenance intervals. The document also covers measurement principles, interferences, and provides examples of applications in wastewater treatment.