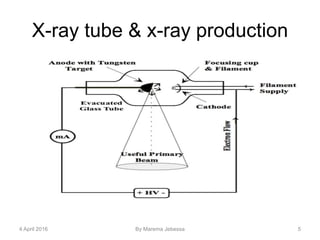

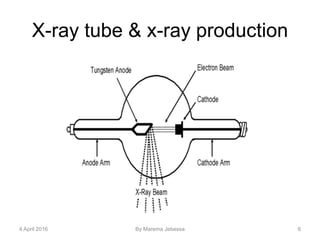

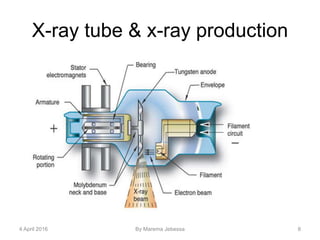

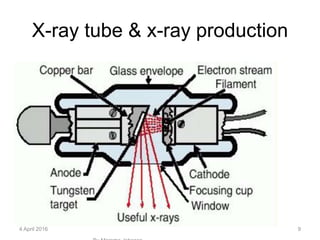

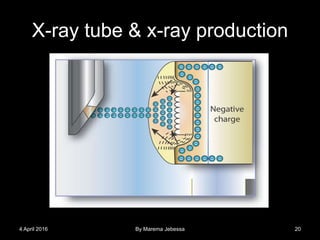

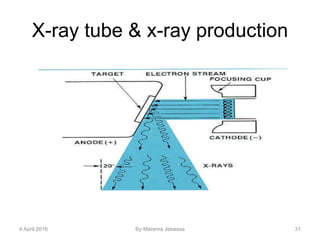

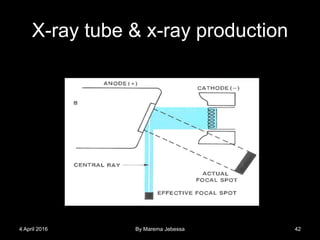

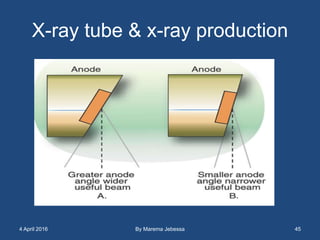

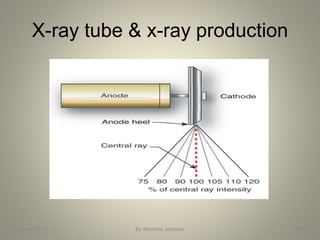

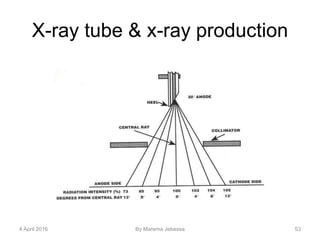

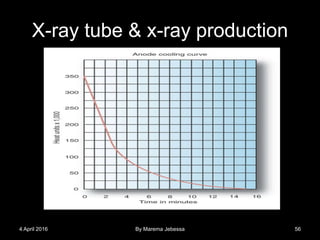

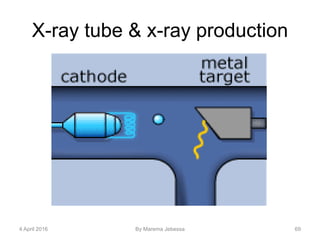

The document discusses the components and functioning of x-ray tubes. It describes the cathode, which contains the filament that emits electrons, and the focusing cup. The anode receives the electrons and contains the focal spot, or target, where x-rays are produced. Factors that determine the focal spot size and heat dissipation from the tube are also examined. The line-focus principle and heel effect are explained in relation to reducing the apparent focal spot size and uneven beam intensity.