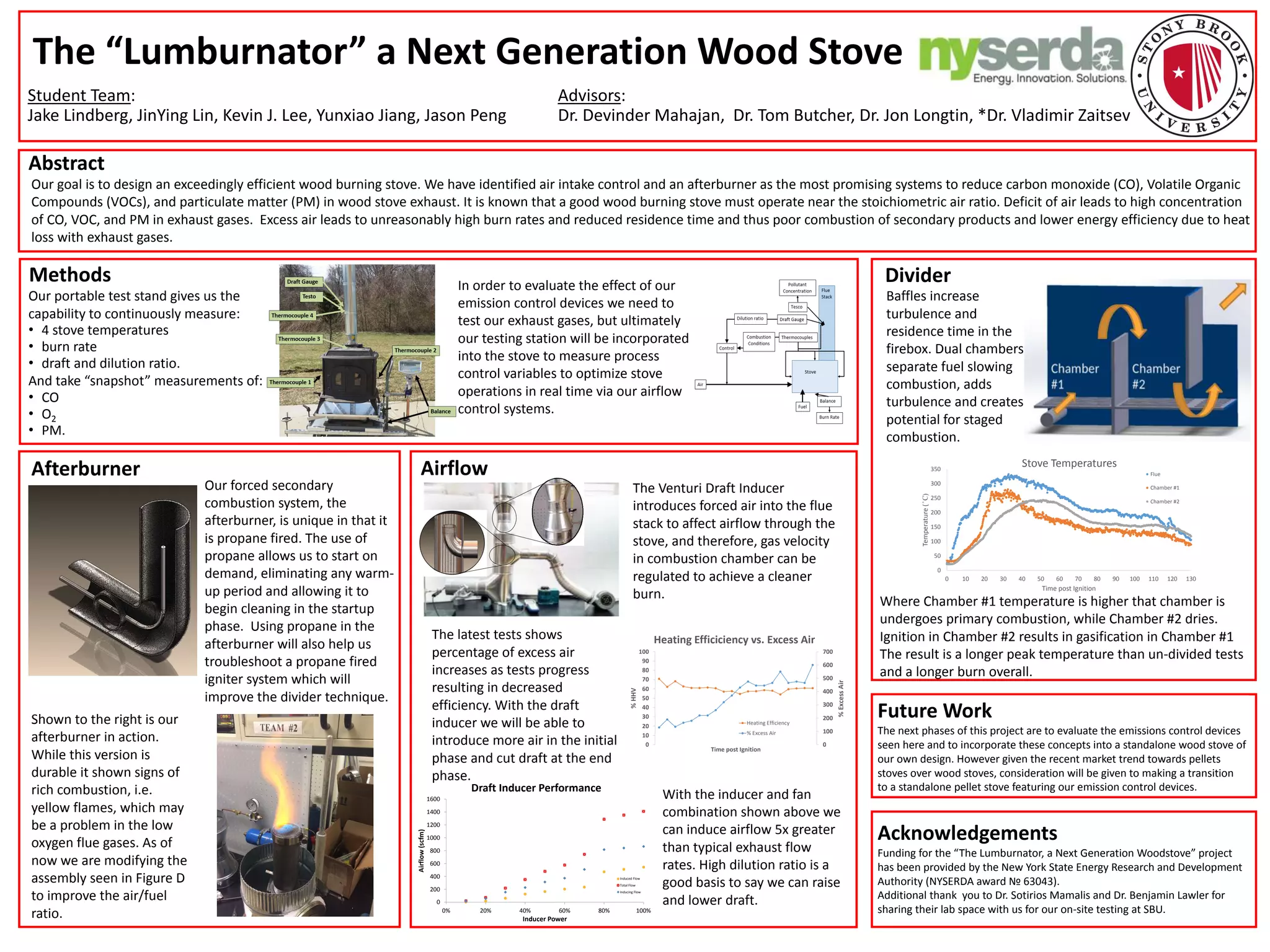

The student team developed the "Lumburnator", a next generation wood stove, with advisors from various universities. Their goals were to improve efficiency and reduce emissions through controlled airflow and an afterburner. Future work will focus on evaluating the emissions control devices and incorporating them into a standalone wood or pellet stove designed by the team. The project was funded by NYSERDA.