This document summarizes the welding procedure qualification record for oxy-fuel welding of carbon steel. It includes 3 key points:

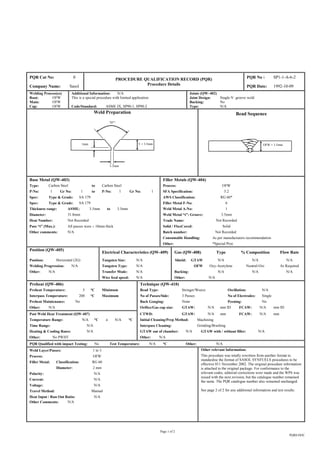

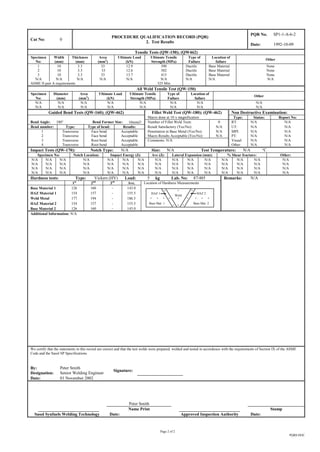

1) The welding process qualified was oxy-fuel welding of a single-V groove weld in the horizontal position using an RG 60 filler metal between 3.5mm thick carbon steel plates.

2) Mechanical testing was performed including tensile and bend tests, which met the requirements of ASME Section IX. Macro examinations also showed acceptable results.

3) Hardness testing found the weld metal had an average hardness of 186.5 HV, while the HAZ areas were 155.5 HV and the base metal was 143 HV, demonstrating acceptable hardness across the joint.