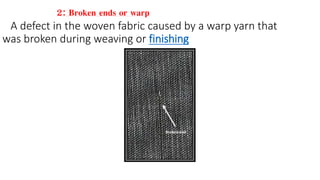

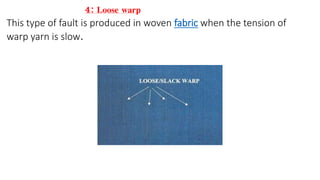

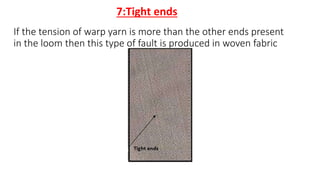

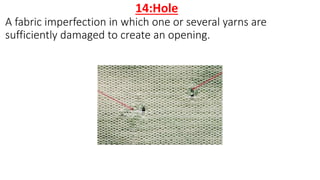

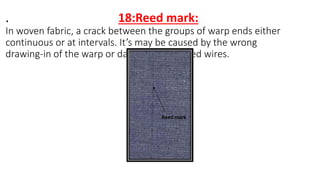

This document summarizes 20 major defects that can occur in woven fabrics, including bad selvedges, broken ends or warp, broken picks or weft, loose warp, loose weft or snarl, double ends, tight ends, float of warp, wrong end color, miss pick, double pick, weft bar, ball, hole, oil spot or stain, tails out, temple mark, reed mark, slab, and thick and thin places. Each defect is defined and explained. The document was presented by Md. Rakibul Hasan, who studied Apparel Manufacturing and Technology and provided his contact information.