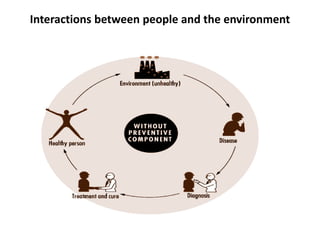

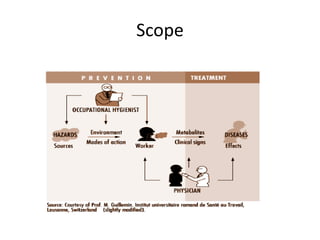

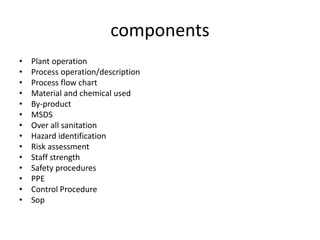

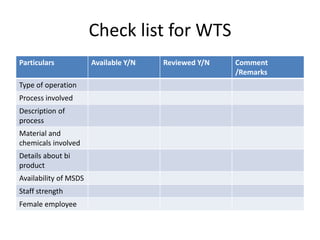

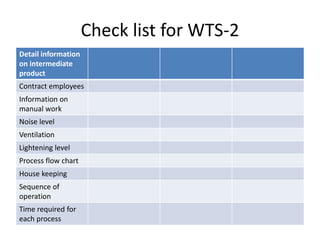

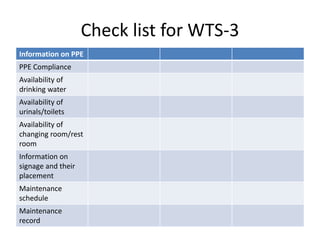

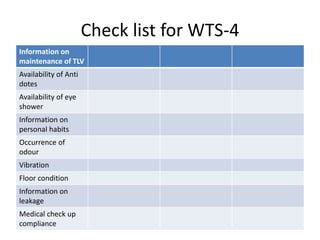

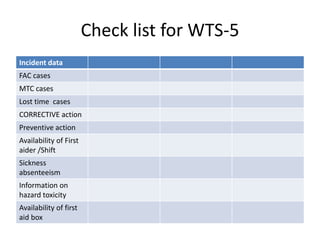

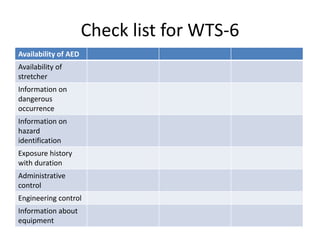

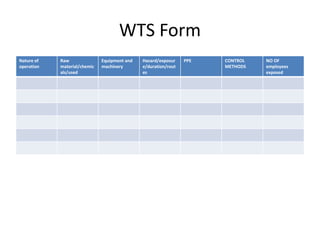

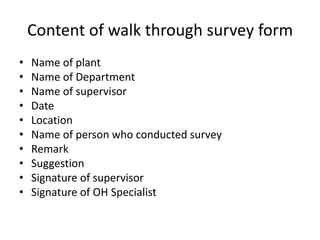

The document outlines the process and purpose of conducting regular workplace walk-through surveys. It defines a walk-through survey as the initial process of identifying occupational hazards by examining the different operations, facilities, and health status of employees at a worksite. The objectives are to identify potential health hazards and assess control measures. Some key advantages include gathering detailed data on the work processes, hazards, and obtaining factual information to guide hazard identification and risk assessment efforts. Checklists are provided as examples of components to examine during a survey such as operations, materials, safety procedures, hazards identified, and corrective actions.