The document discusses electrical discharge machining (EDM) and compares conventional EDM to rotary EDM where the workpiece is rotated. It finds that rotary EDM increases the material removal rate compared to conventional EDM due to enhanced flushing of debris from the gap. Both material removal rate and surface roughness improve with increased rotation speed. Higher pulse current and longer pulse-on time negatively impact surface roughness by producing more molten material and a thicker recast layer, while rotation helps remove this recast layer to yield better surfaces.

![9

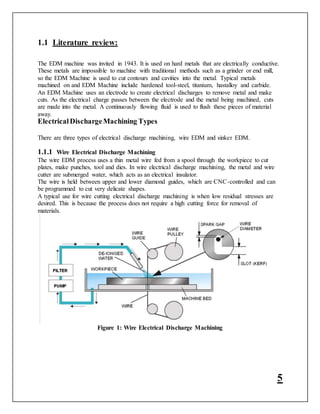

2.1 Introduction

Electrical-discharge machining (EDM) is extensively used for high strength materials. A major

advantage of EDM is that the tool and the workpiece do not come into contact, thus eliminating

chatter and vibration problems and allowing small or thin components to be machined without

mechanical force [1,2]. As the electrical breakdown of the dielectric occurs, an electrical arc is

generated between the cathode and anode. During the period of on-time, the discharge energy

produces a very high temperature at the point of the spark on the surface of the workpiece, and

removes the material by melting and vaporization. The top surface of the workpiece resolidifies

and cools subsequently at a very high rate. The surface produced by EDM is largely influenced

by the discharge energy. This process produces the slightly dimpled surface (the increased

surface roughness), which will facilitate crack initiation on the surface. After the electrical-

discharge treatment, high tensile residual stresses often induce damage such as microcracks or

pinholes in the surface layer, which reduce the strength. The fracture strength of the material

after EDM varies significantly depending on the pulsed current applied [3–8].

During EDM, the concentration of debris in the gap increases drastically, impeding the further

removal of the materials from the gap. Fresh dielectric fluid has to enter for continuous electrical

discharge. The basic parameters of conventional EDM are the pulsed current, pulse on-time, and

pulse off-time. In rotary EDM, an additional parameter, i.e., the rotation of the electrodes, is

considered. Researchers use the techniques of applying rotation or orbital motion to the electrode

to ensure adequate flushing of the gap and to obtain better machining performance [9–10]. The

authors believe that the rotating motion of the workpiece can also rapidly remove debris from the

gap, allowing fresh dielectric to enter for effective spark discharge. This method will benefit

certain axial–symmetrical parts used in molds and dies made of difficult-to-machine materials

when the parts are electrical-discharge machined. In the present investigation, the workpiece of

AISI D2 tool steel is mounted on a rotating workpiece clamper driven at a desired speed. The

material removal rate (MRR) and surface roughness are compared with those from conventional

EDM.

Figure 4: EDM Die Sinker](https://image.slidesharecdn.com/workpiecerotationonedm-190714130947/85/Workpiece-rotation-on-edm-9-320.jpg)

![16

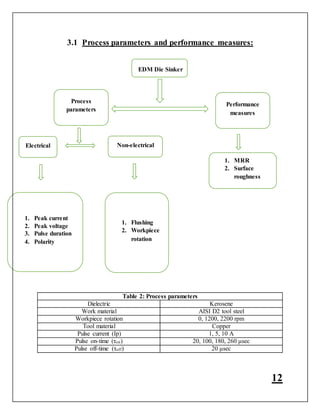

5.1 Material removal rate

The MRR was measured for both conventional and rotary EDM modes. Figure 7 shows the

relationship between the pulsed current and MRR at different workpiece rotation speeds.

According to this figure, the rotary EDM mode was associated with a higher MRR than

conventional EDM.

At a constant speed, the MRR increased with an increasing pulsed current. At a pulsed current of

1 A, workpiece rotation only slightly affected MRR. Faster workpiece rotation implied more

effective flushing of dielectric fluid and, ultimately, a higher MRR.

Figure 8 shows the effect of pulse on-time on material removal rates at different rotation speeds.

In conventional EDM, the MRR initially increased with increasing pulse on-time owing to the

higher energy input rate. A peak value was reached as the pulse on-time increased beyond a

certain value. The material removal in one spark became so large that the inter-electrode gap

condition for the next discharge was disturbed. This discharge instability induced by debris at the

gap lowered the discharge efficiency, as observed by Soni and Chakraverti [9].

For example, the eroded chips filling the gap will hinder a sound discharge. Experimental results

indicated that the maximum removal rate was 15.7 mm3min-1. The maximum MRR in

conventional EDM had an optimum pulse on-time of 180 μsec. The MRR in rotary EDM was

approximately twice as high as in conventional EDM at the same pulse on-time.

Figure 7: Effect of pulsed current on MRR at different workpiece speeds (pulse on-time 20 μsec).](https://image.slidesharecdn.com/workpiecerotationonedm-190714130947/85/Workpiece-rotation-on-edm-16-320.jpg)

![19

A comparison of Figures 9 and 10 shows that the surface roughness constantly increased with

pulsed current as well as pulse on-time. Both quantities delivered thermal energy to the

machining location. More molten material was produced, whereas complete flushing by the

dielectric fluid became more difficult, and the resulting larger recast layer worsened the surface

finish. An excellent machined finish could be obtained by setting the machine parameters at a

low pulsed current and a small pulse on-time combined with a high workpiece rotation speed, but

this approach was more time consuming. The trends observed for conventional EDM agree with

the results reported by previous investigators [Lee et al. (15)]. The following general conclusion

can be made. In conventional EDM, insufficient flushing in the limited space results in the

stagnation of the dielectric. The debris particles become suspended in the gap and cause short

circuits, reducing machining performance. During rotary EDM, rotation of the workpiece

enhances the dielectric fluid circulation and provides a centrifugal force of flow in the gap.

Hence, the machining residue in the gap is discharged rapidly. This rapid discharge improves the

machining stability, removes more material from the specimen, and produces better surface

roughness. Figure 11 schematically shows this effect.

Figure 11:Schematic of machining in conventionaland rotary EDM. (a) Insufficient flushing

in conventional EDM. (b) Enhanced flushing in rotary EDM.](https://image.slidesharecdn.com/workpiecerotationonedm-190714130947/85/Workpiece-rotation-on-edm-19-320.jpg)