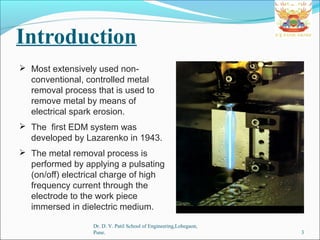

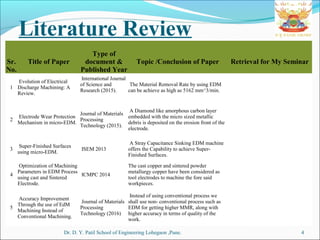

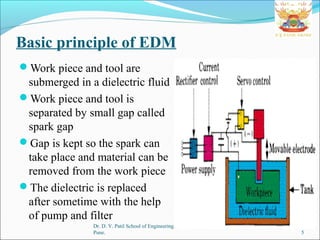

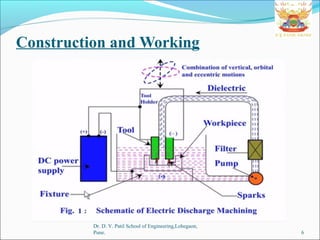

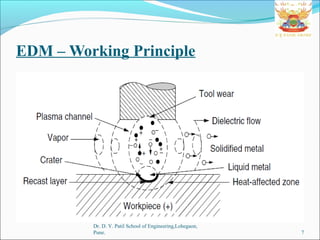

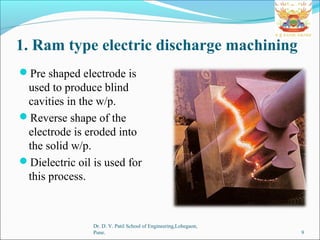

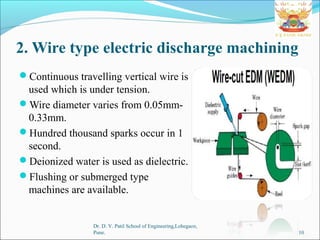

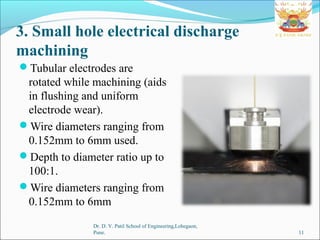

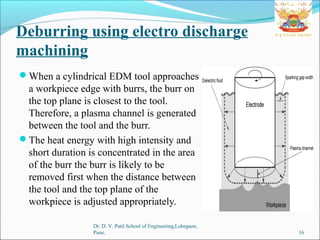

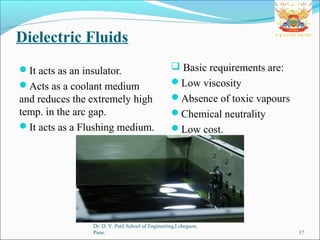

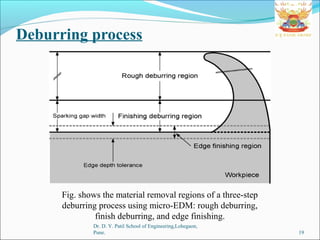

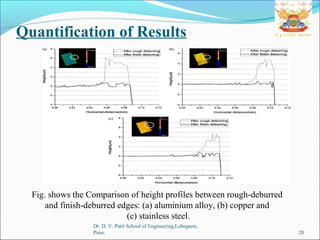

The document presents a seminar on Electrical Discharge Machining (EDM), detailing its basic principles, types, and applications. It highlights the effectiveness of EDM in metal removal through electrical spark erosion, its advantages like burr-free operation, and limitations such as rapid electrode wear. Additionally, the seminar reviews relevant literature and methodologies for deburring using EDM, emphasizing the importance of dielectric fluids in the process.