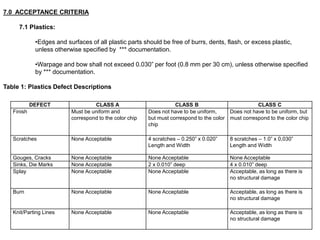

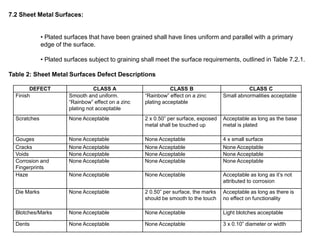

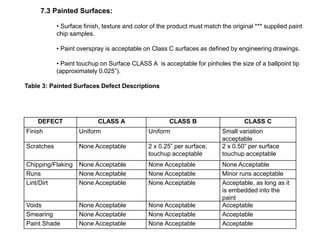

This document establishes workmanship standards for surface finishes of products produced by or supplied to xxx. It defines three classes (A, B, C) of surfaces based on how frequently they are viewed, and the corresponding inspection requirements. It provides definitions of common defects and the acceptance criteria for each class of surfaces, including limits for scratches, dents, sinks, die marks and other defects on plastic, sheet metal and painted surfaces. Strict standards are defined for Class A surfaces that are most visible to customers.