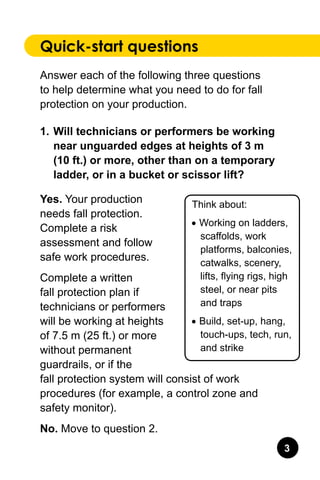

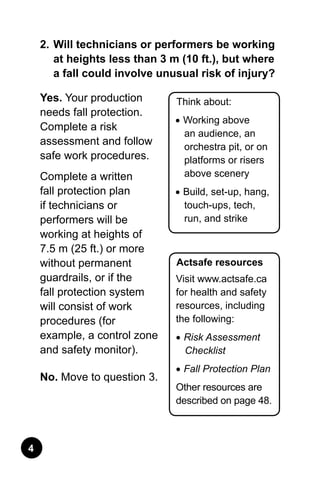

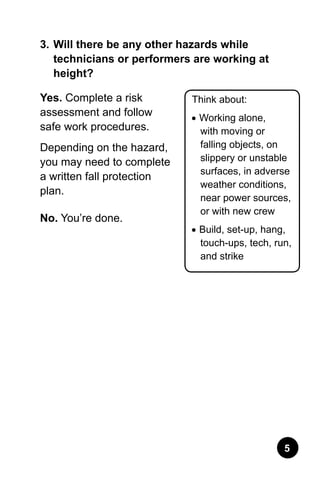

This document provides a safety primer for employers, performers, and technicians working at heights in British Columbia's live performance industry. It outlines health and safety requirements and safe work practices. Key points include:

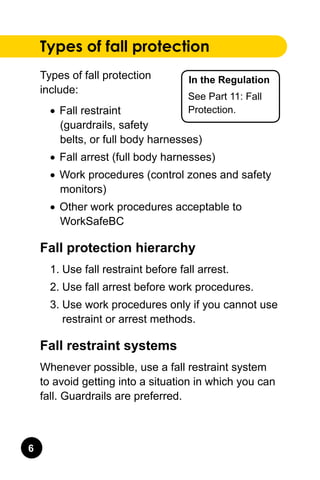

- Types of fall protection include fall restraint, fall arrest, work procedures, and exceptions for live performance. Fall restraint and arrest use harnesses and lanyards, while work procedures use control zones and safety monitors.

- Fall protection plans are required when working at heights over 7.5 meters without guardrails, where falls pose unusual risks, or when using work procedures. Plans must specify hazards, prevention/mitigation methods, assembly/use of equipment, and rescue plans.

- Employers must