This document contains information from a rigging and slinging training course, including:

1. An overview of relevant legislation such as LOLER, PUWER, and HASAWA.

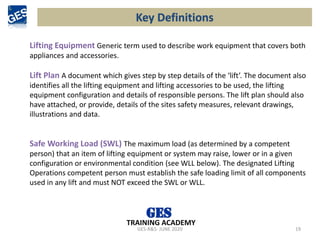

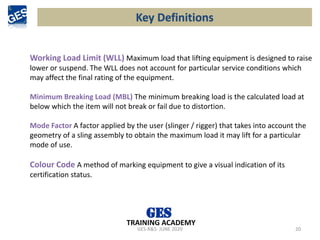

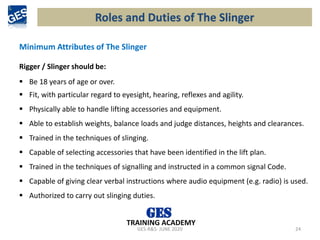

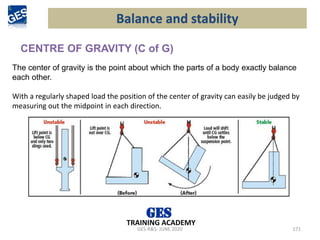

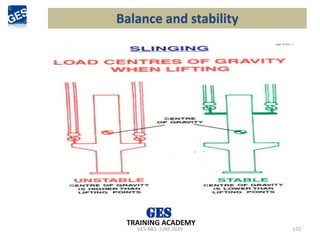

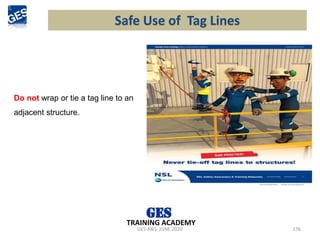

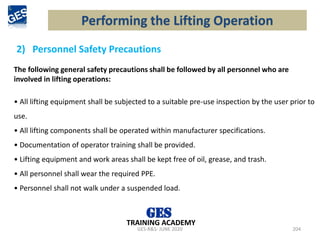

2. Definitions of key lifting terms and the roles and responsibilities of riggers.

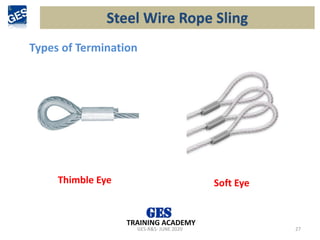

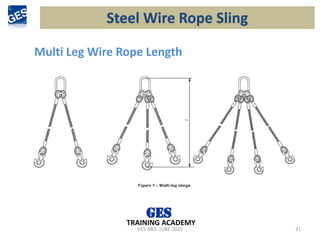

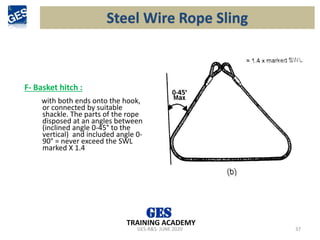

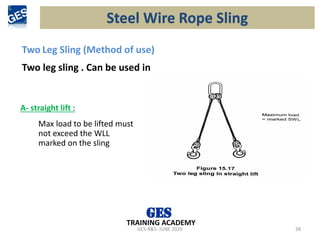

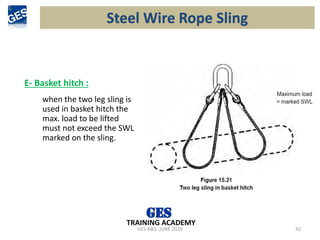

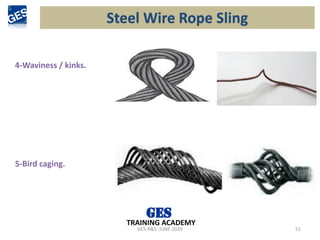

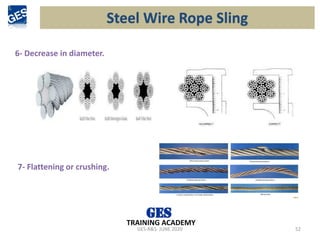

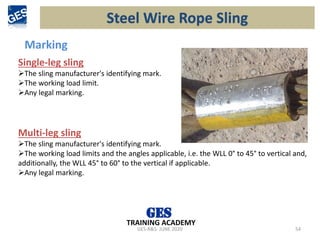

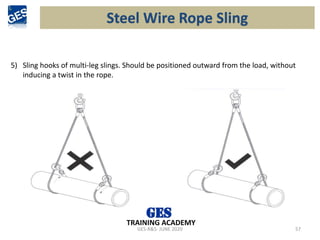

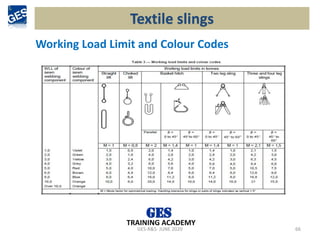

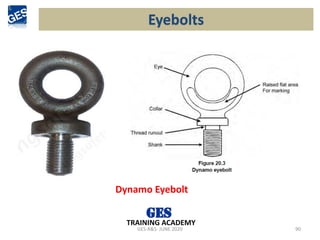

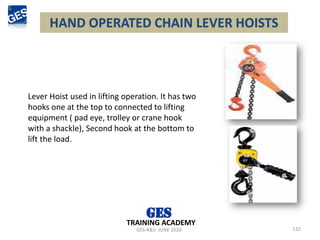

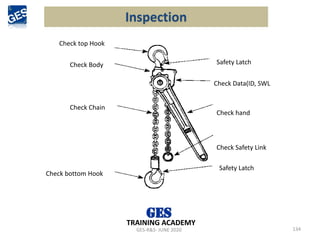

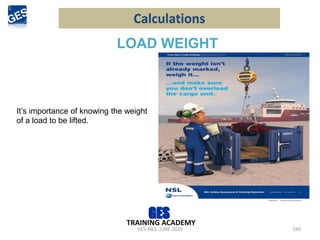

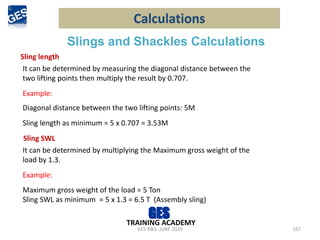

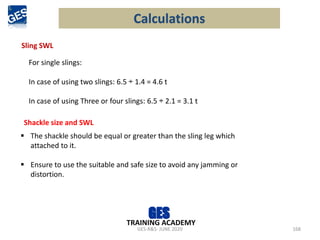

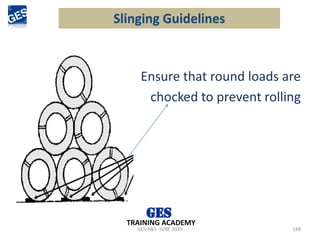

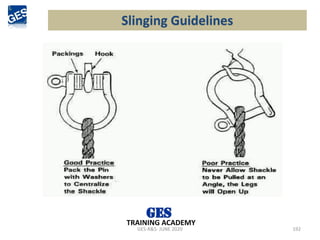

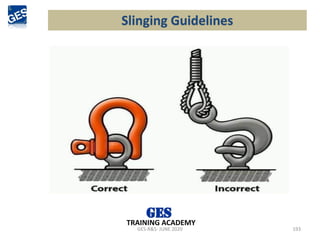

3. Guidelines for inspecting and using various types of wire rope slings, including maximum load limits for different configurations.