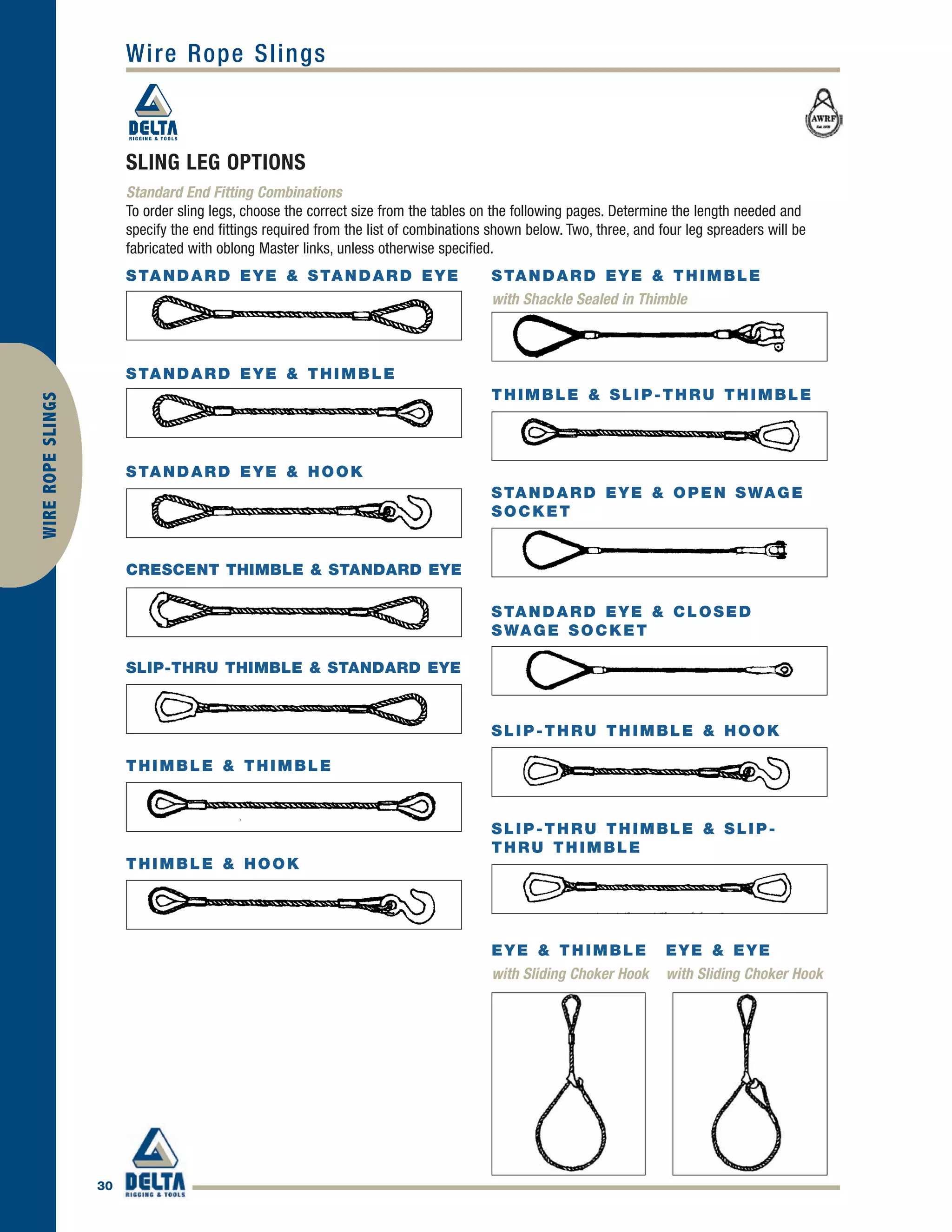

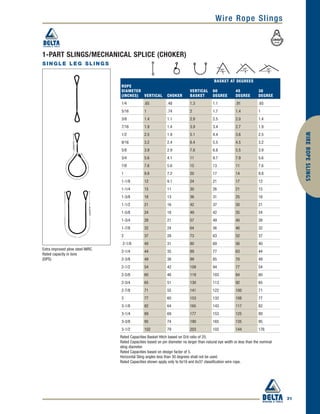

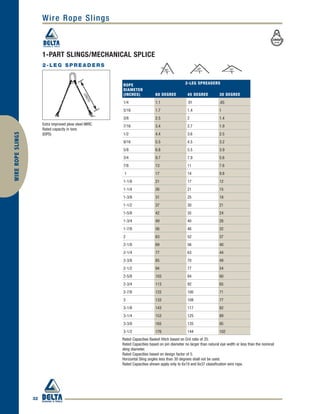

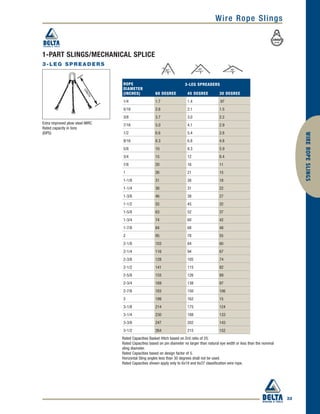

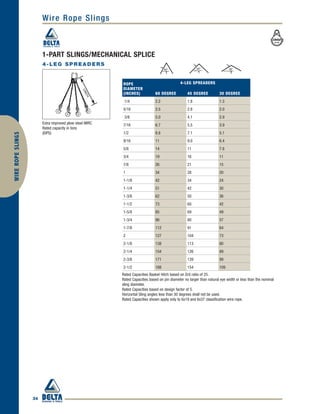

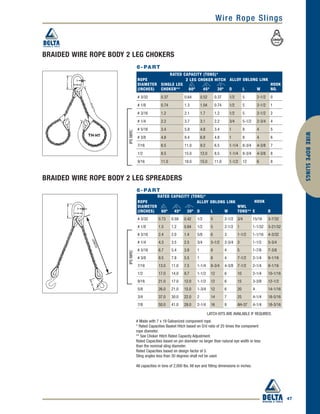

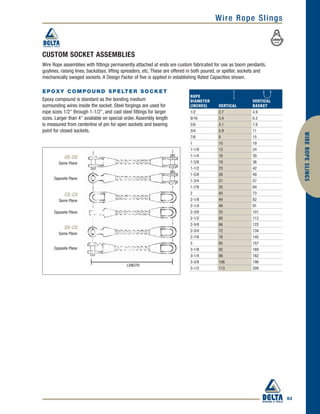

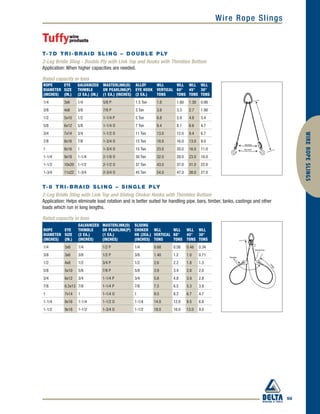

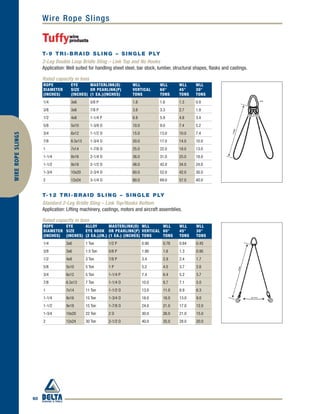

This document provides specifications for various wire rope sling configurations including single and multi-leg slings. It includes rated capacity tables for different sling designs made from extra improved plow steel or stainless steel wire rope. The tables provide capacity ratings in tons for vertical, choker, and basket configurations at various sling angles based on the rope diameter and number of legs. Standard end fitting combinations for ordering sling legs are also listed.