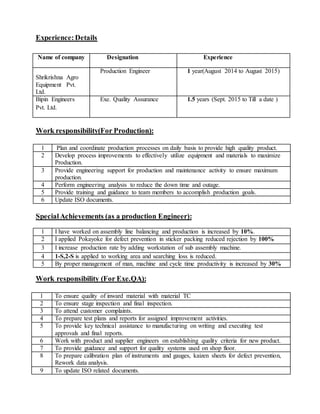

Rushikesh Ramesh Deshpande is seeking a challenging job where he can utilize his knowledge and skills. He has 2.5 years of experience as a Quality Engineer and Production Engineer for food processing equipment and solar water heaters. He holds a Bachelor's degree in Mechanical Engineering with 66.60% and has expertise in techniques like 5S, Kaizen, Pokayoke, and Lean. His responsibilities have included quality inspection, reducing defects, improving processes, meeting production goals, and updating documentation. He aims to further reduce rejection rates and increase productivity through quality initiatives.