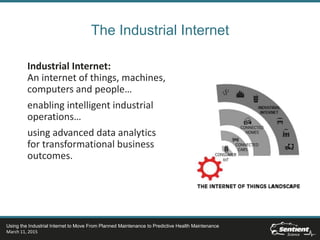

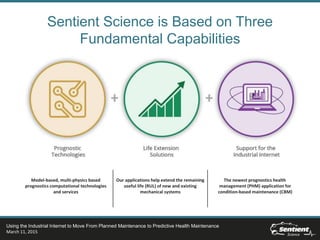

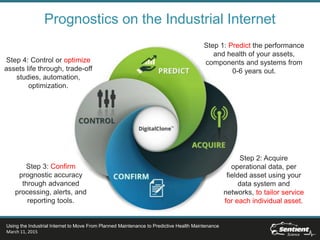

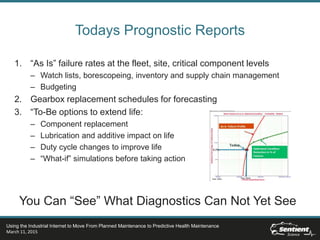

The document discusses the use of the industrial internet to transition from planned maintenance to predictive health maintenance, highlighting the economic potential and benefits of prognostics for industrial equipment. It outlines the role of the Industrial Internet Consortium in fostering collaboration among industries, academia, and government to develop standardized protocols and innovative solutions. Key points include the economic impact estimates and the advantages of using advanced data analytics to enhance the longevity and performance of assets.