Embed presentation

Download as PDF, PPTX

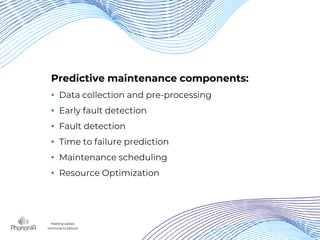

The document discusses the benefits of predictive maintenance for valves, emphasizing its role in diagnosing asset conditions to optimize maintenance schedules. Key advantages include cost savings, prevention of unexpected shutdowns, and increased safety and production efficiency. Predictive maintenance leverages machine learning for diagnostics and relies on data collection, early fault detection, and resource optimization.