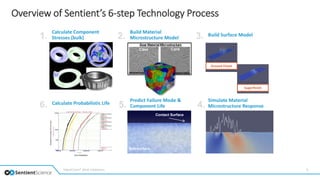

The document outlines Sentient Science's digitalclone® technology, which utilizes a 'small data' approach to predict component failures in wind turbines, allowing operators to anticipate issues and extend the life of critical components. It emphasizes the financial benefits of this technology, including significant maintenance cost reductions and informed operational decisions. Additionally, it provides validation data correlating predictions with actual failures and improvements gained through the implementation of these predictive models.