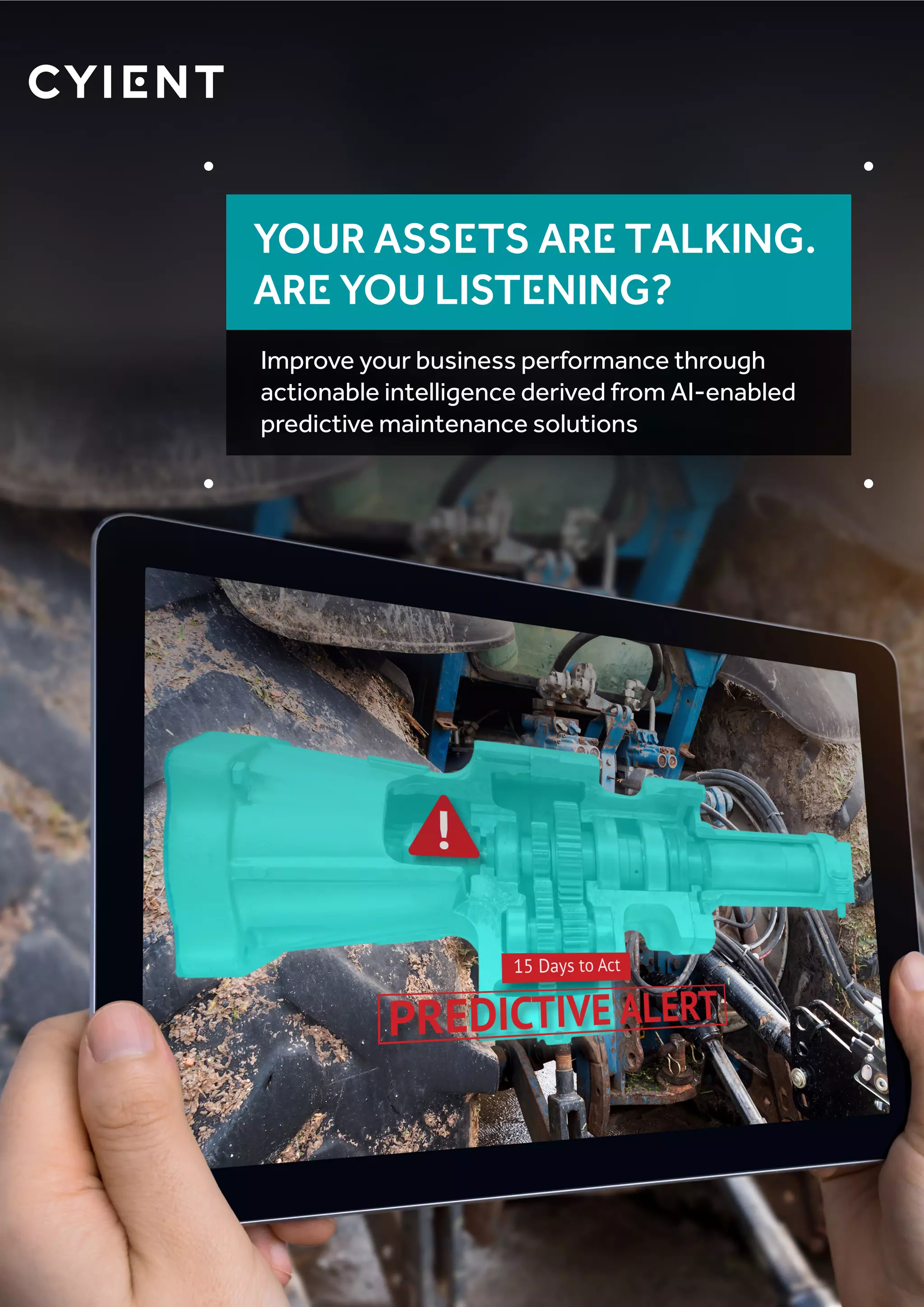

An AI-enabled predictive maintenance solution can help companies improve business performance by analyzing asset data to derive actionable insights. It can help reduce unplanned downtime by 11% on average, lower maintenance costs by 30%, and minimize breakdowns by up to 70%. An effective predictive maintenance solution should leverage existing backend technologies, apply models and algorithms to data to derive insights, and provide a flexible front-end dashboard integrated with existing tools.