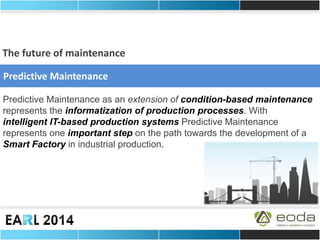

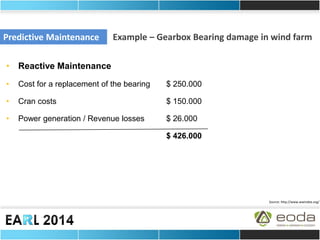

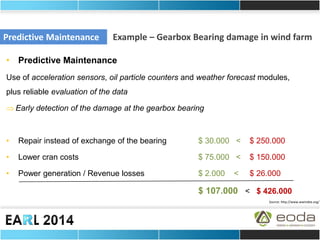

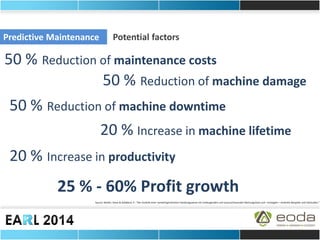

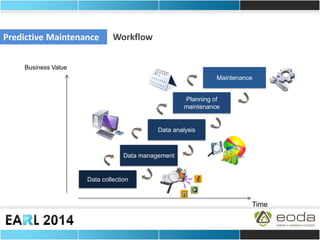

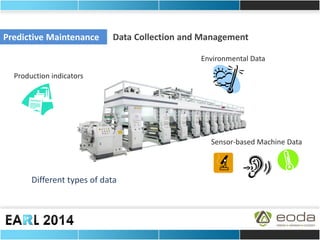

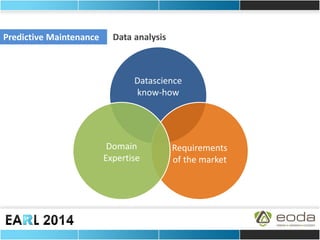

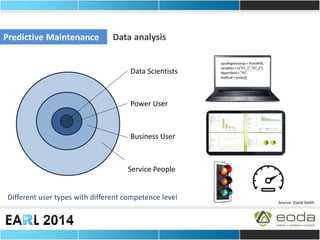

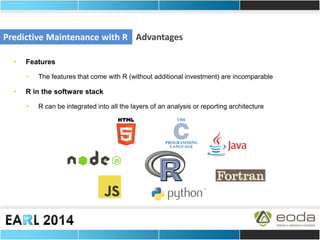

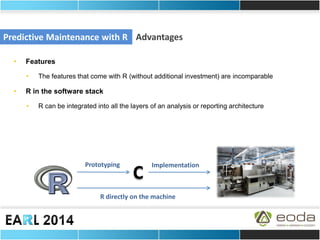

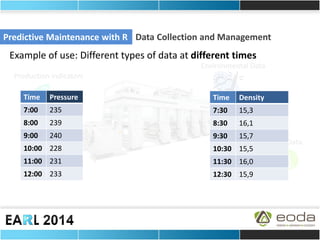

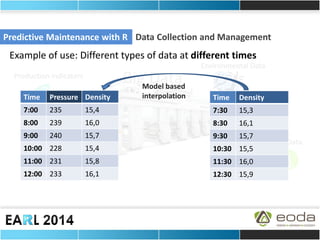

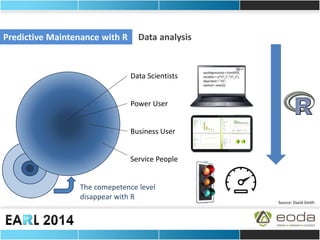

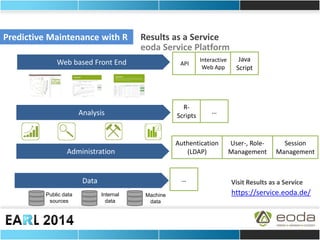

The document discusses predictive maintenance and its significance within industrial production, emphasizing its role in optimizing maintenance strategies and reducing costs. It highlights the advantages of using R for predictive maintenance, such as cost-effectiveness, reliability, and integration capabilities into analysis architectures. Examples provided demonstrate the substantial cost savings and efficiency improvements achievable through predictive maintenance practices.