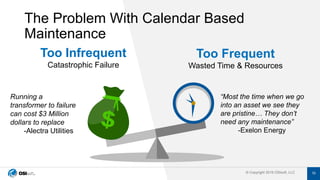

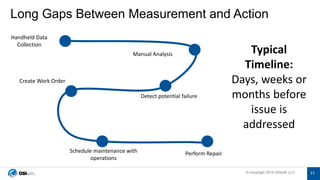

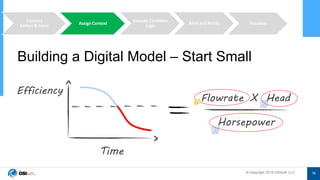

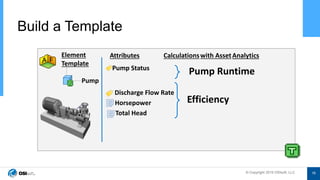

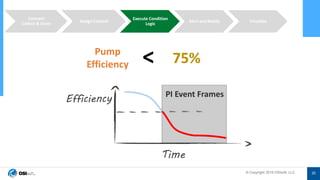

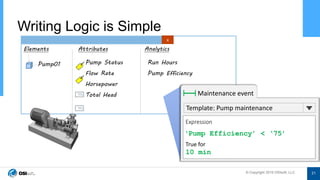

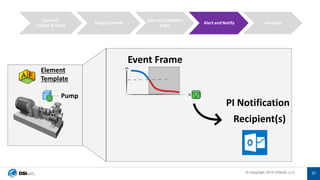

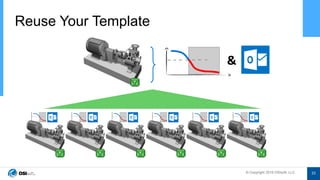

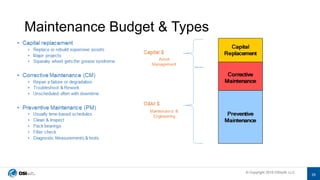

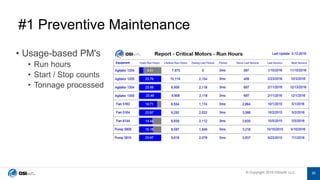

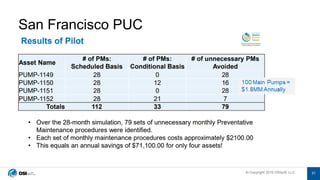

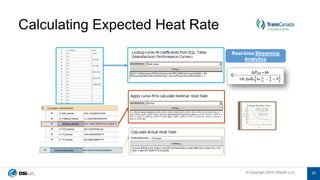

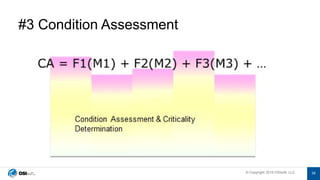

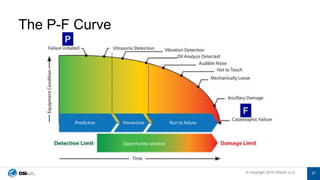

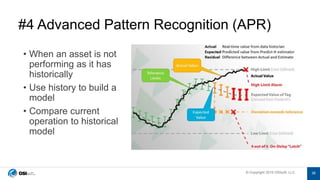

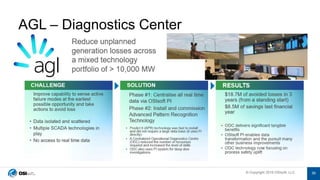

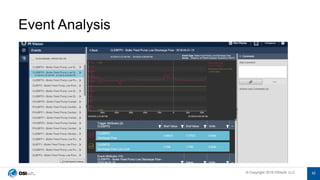

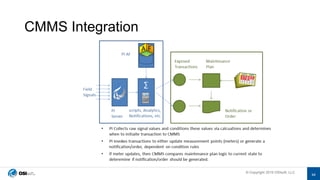

The document discusses the use of the PI System for condition-based maintenance (CBM), outlining its advantages over traditional maintenance methods such as reactive, preventive, and predictive maintenance. It presents various approaches to implementing CBM, including monitoring asset health and using analytics for performance optimization. Additionally, it provides real-world examples and resources for organizations looking to adopt CBM practices.