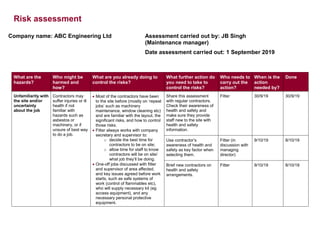

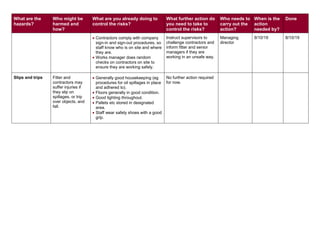

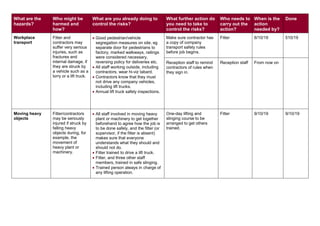

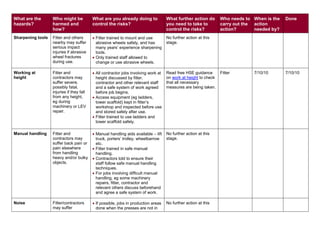

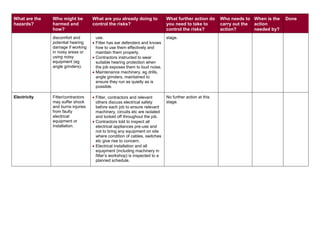

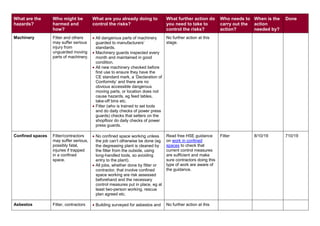

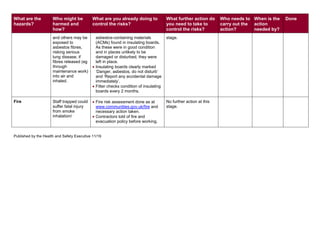

This document outlines a risk assessment conducted by a maintenance manager at ABC Engineering Ltd for maintenance work in a factory that employs 40 people. The assessment identifies various hazards such as slip and trip risks, noise exposure, working at height, and electrical safety, outlining existing controls and required actions to mitigate these risks. It emphasizes the importance of tailoring the assessment to specific workplace hazards and ensuring ongoing communication and training for contractors regarding health and safety practices.