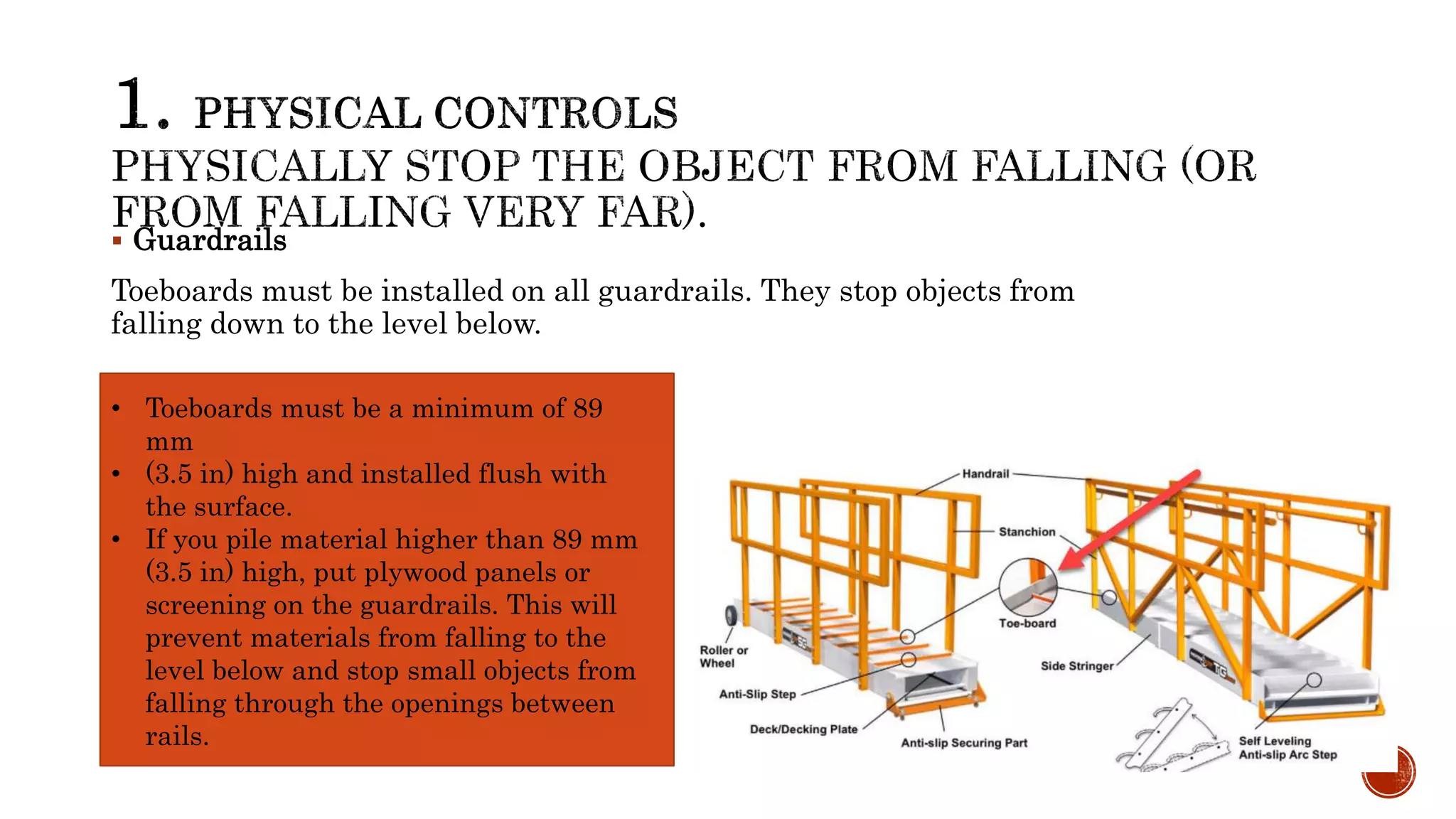

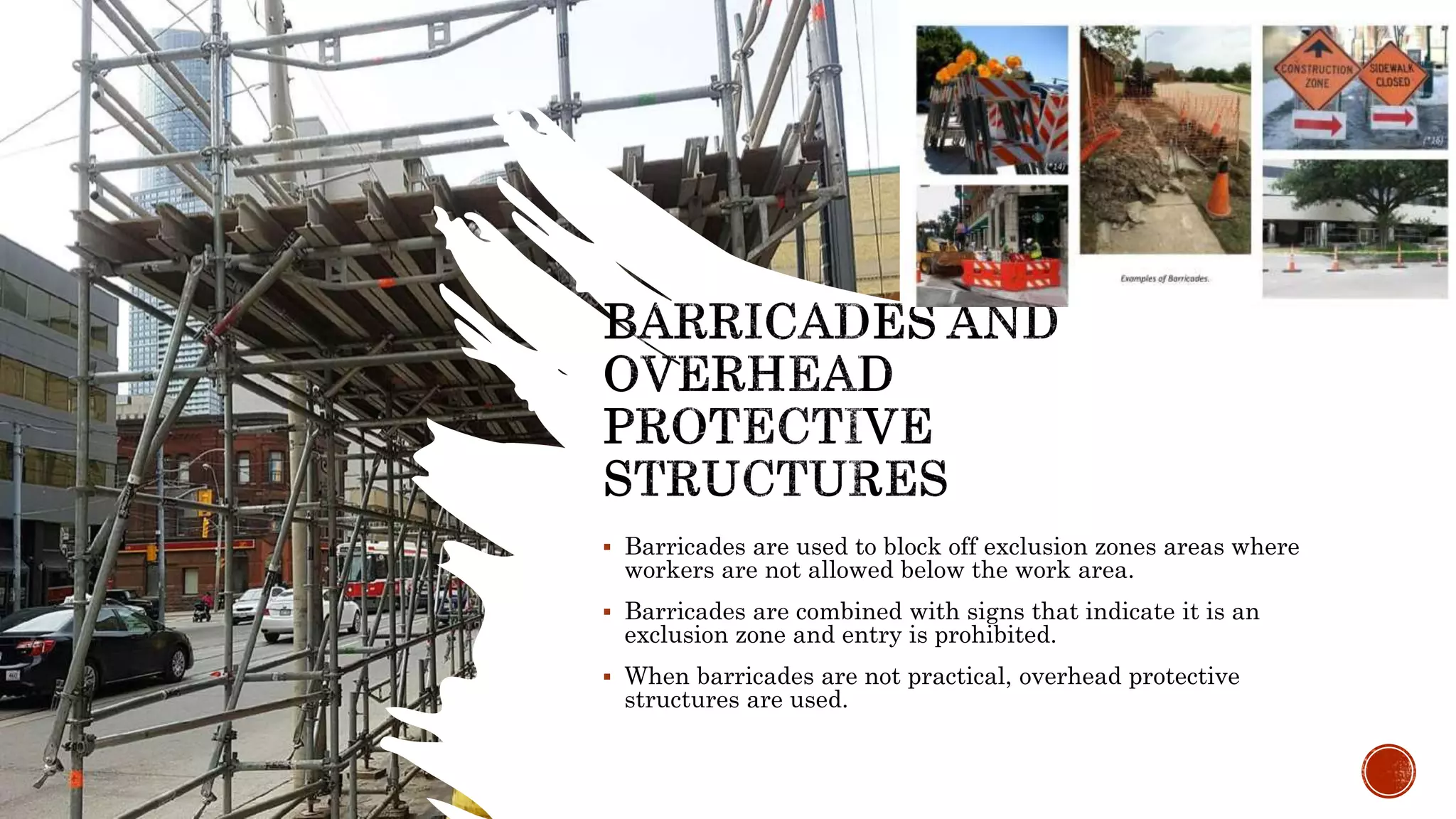

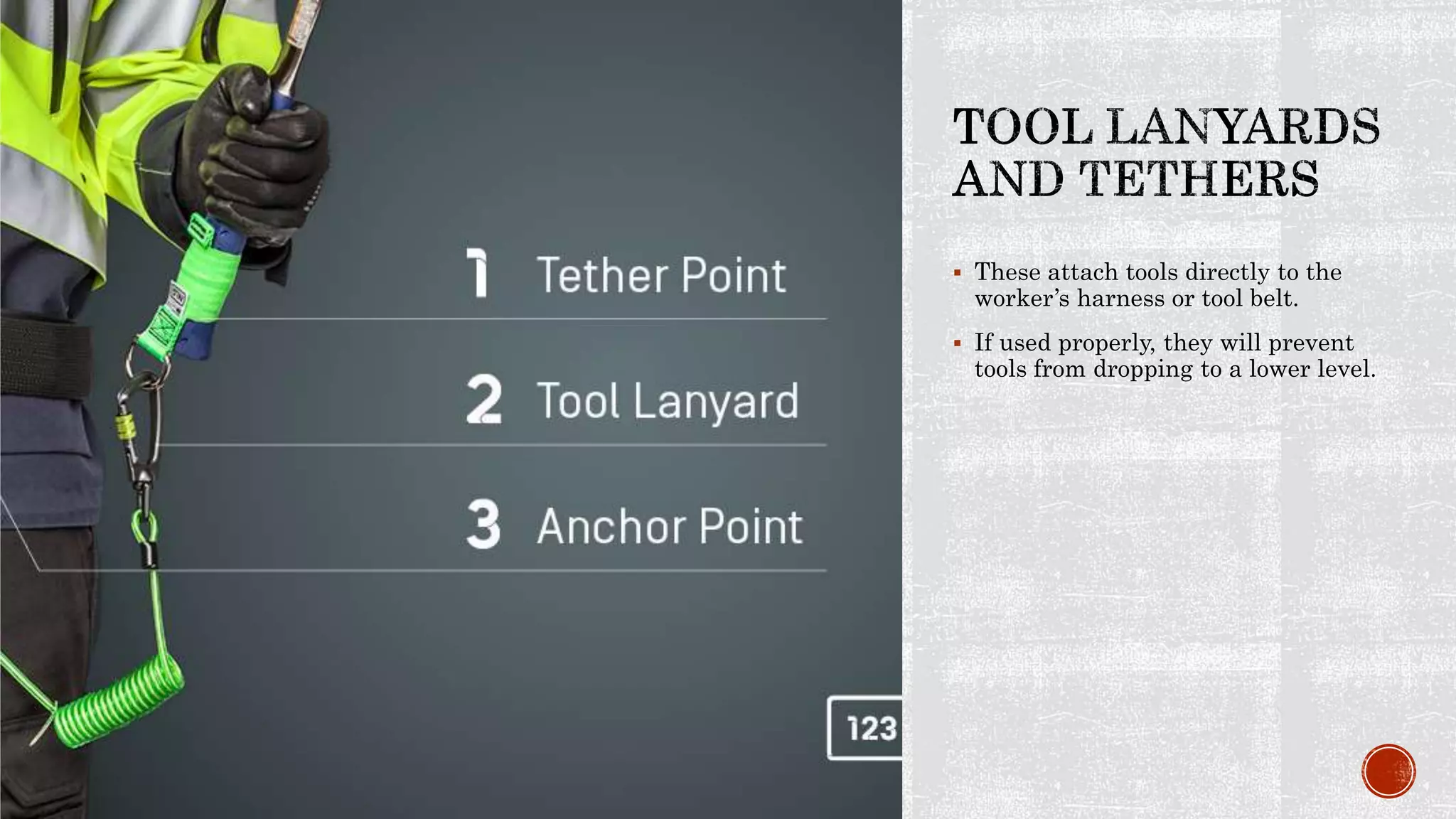

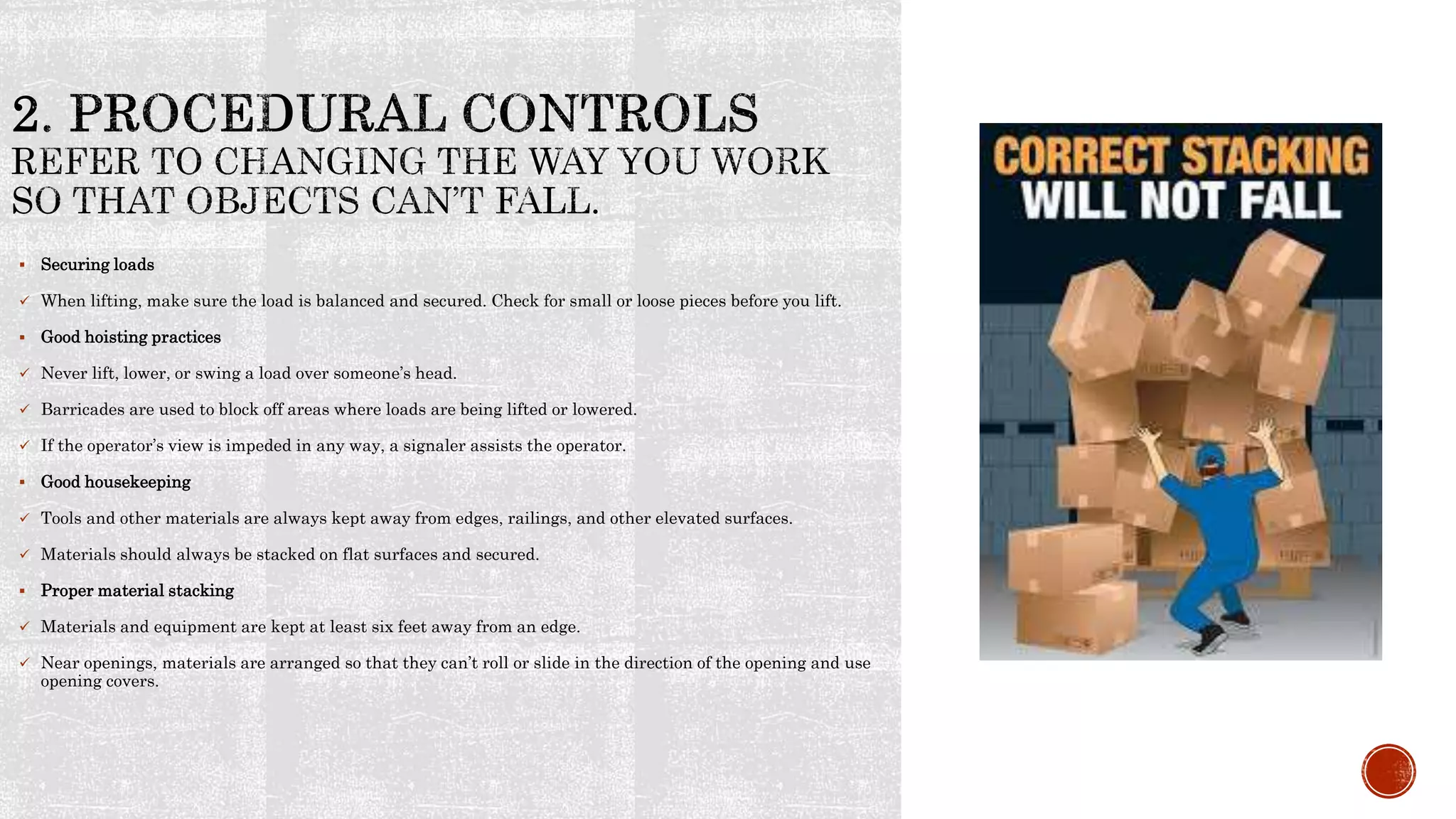

The document discusses hazards from falling objects in the workplace. It notes that common injuries from falling objects include bruises, fractures, strains and sprains. Objects that can fall range in size from large items like roof trusses to small items like tools and fasteners. Even small objects like bolts dropped from heights can cause serious injury or death. The document outlines physical and procedural controls to prevent falling object injuries, including guardrails, barricades, tool tethers, material carts, securing loads, good hoisting practices, housekeeping, and proper material stacking.