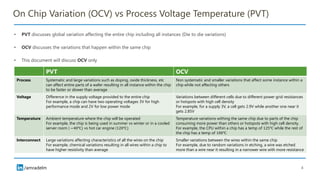

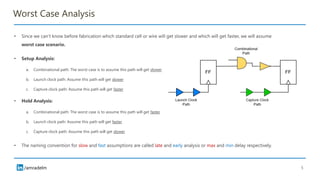

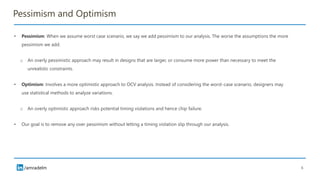

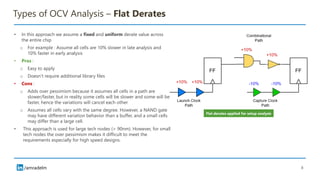

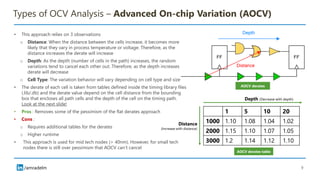

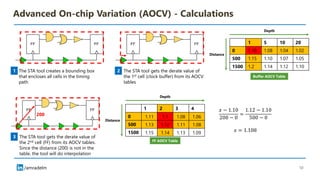

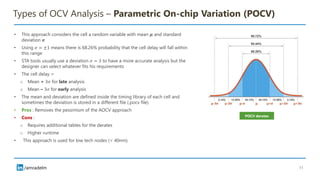

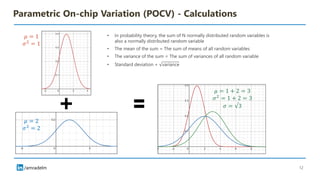

The document discusses on-chip variation (OCV), which arises from various factors like manufacturing process variations, temperature fluctuations, and voltage supply differences, affecting the performance of integrated circuits. It distinguishes OCV from global variations and explains approaches for analyzing OCV, including pessimistic and optimistic strategies, flat derates, advanced on-chip variation (AOCV), and parametric on-chip variation (POCV). The goal of these analyses is to balance design safety with performance efficiency while addressing specific challenges posed by variations within integrated circuits.

![/amradelm

Variations in interconnect

Temperature variations

on chip [2]

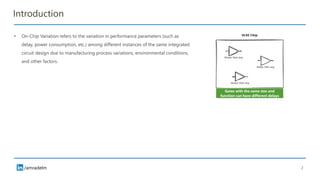

Sources of OCV

• Process Variations: Variations in the manufacturing process can lead to

differences in transistor characteristics (such as threshold voltage, oxide

thickness, doping concentration, etc.)

• Temperature Variations: Temperature fluctuations across the chip during

operation can cause variations in transistor behaviour and interconnect delays.

• Supply Voltage Variations: Fluctuations in the supply voltage, due to factors like

power supply noise or voltage drop, can affect the performance of transistors

and circuits.

• Interconnect Variations: Variations in interconnect resistance, capacitance, and

parasitic effects can lead to differences in signal propagation delay and power

consumption

MOSFET under microscope [1]

3](https://image.slidesharecdn.com/onchipvariationocv-241012070911-b1d156c9/85/VLSI-Static-Timing-Analysis-Timing-Checks-Part-5-On-Chip-Variation-3-320.jpg)

![/amradelm

Citations

• [1] https://www.bbvaopenmind.com/en/technology/innovation/mini-transistors-technological-revolution-20th-century/

• [2] L. Chen, W. Jin and S. X. . -D. Tan, "Fast Thermal Analysis for Chiplet Design based on Graph Convolution Networks," 2022 27th

Asia and South Pacific Design Automation Conference (ASP-DAC), Taipei, Taiwan, 2022, pp. 485-492, doi: 10.1109/ASP-

DAC52403.2022.9712583.](https://image.slidesharecdn.com/onchipvariationocv-241012070911-b1d156c9/85/VLSI-Static-Timing-Analysis-Timing-Checks-Part-5-On-Chip-Variation-22-320.jpg)