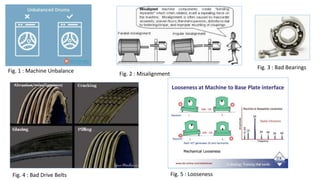

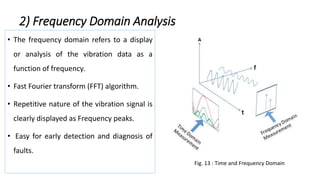

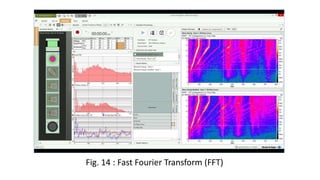

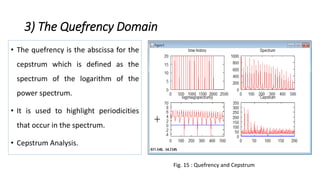

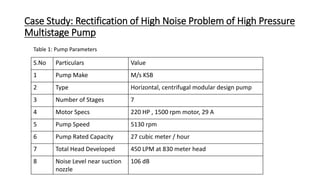

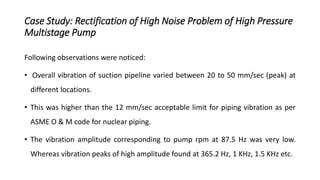

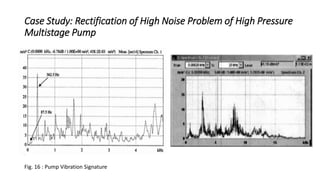

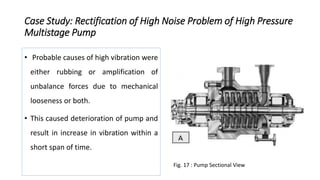

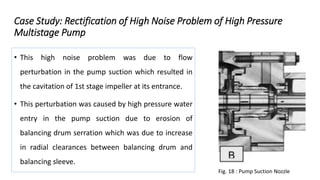

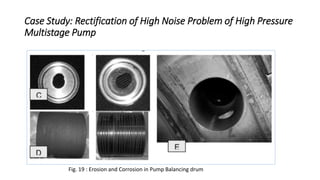

This document discusses vibration signature analysis and provides a case study example. It begins with an introduction to machine fault detection and an overview of vibration signature analysis techniques in the time, frequency, and quefrency domains. It then presents a case study of a high pressure multistage pump that was experiencing high noise levels. Analysis found the noise was caused by cavitation of the first stage impeller due to flow perturbations from erosion of serrations on the pump's balancing drum. Replacing the worn balancing drum components resolved the noise issue.