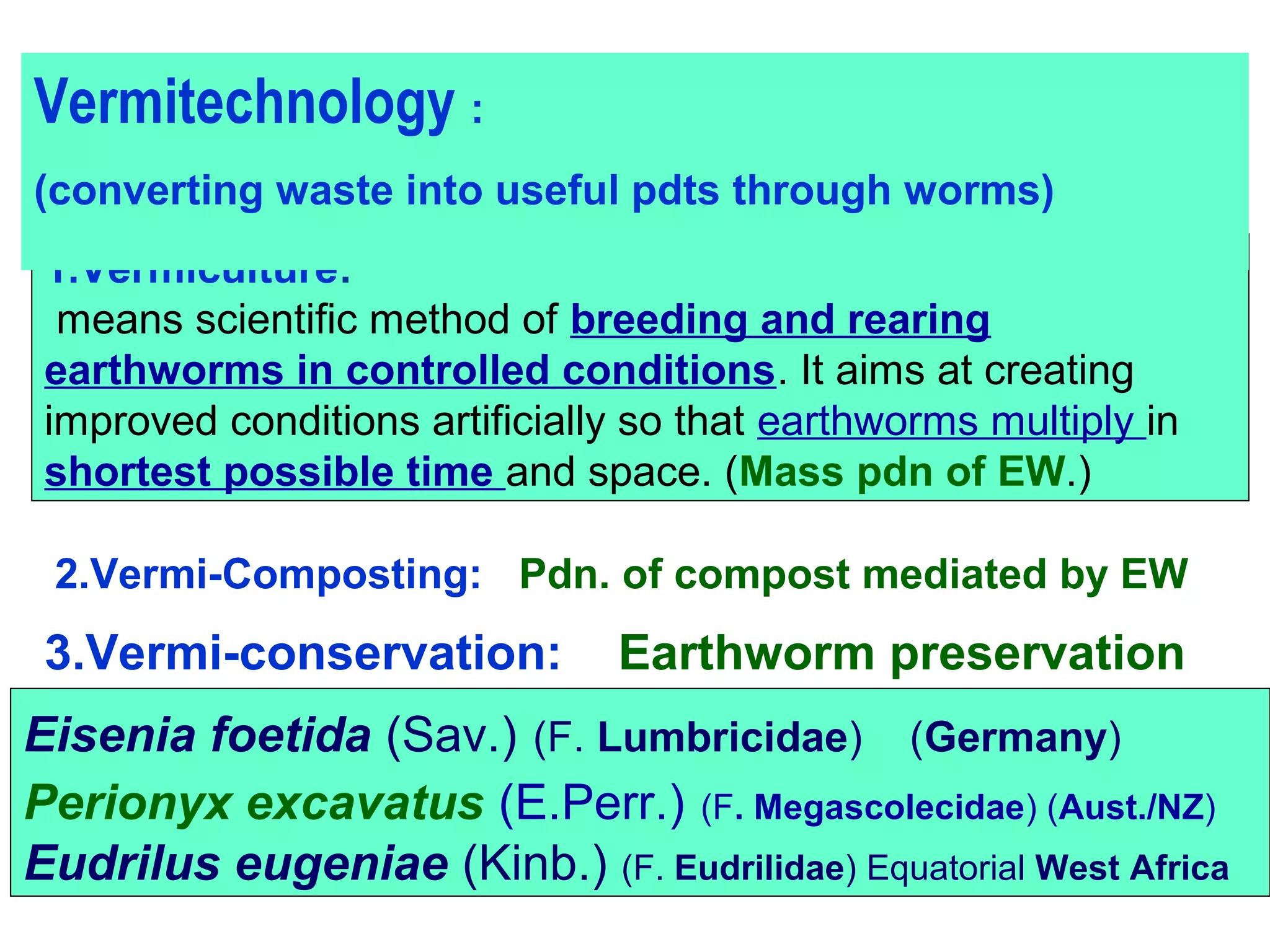

This document provides information on vermicomposting and phosphocomposting. It begins by defining vermicompost as compost produced through the metabolic activities of earthworms. It then discusses various earthworm species suitable for vermicomposting, including Eisenia fetida and Perionyx excavatus. The document outlines the vermicomposting process and describes the characteristics of good quality vermicompost. It also notes the benefits of vermicompost for soil and plant health. The document concludes by defining phosphocompost as compost prepared by adding rock phosphate and phosphate solubilizing microorganisms to organic wastes to solubilize phosphorus from the rock phosphate during decomposition.