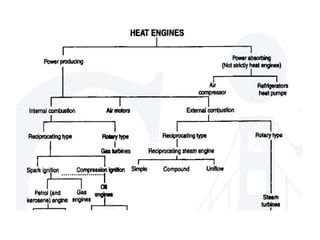

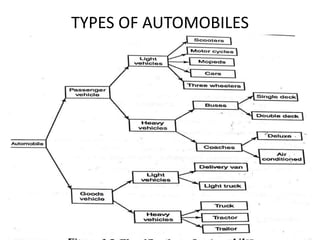

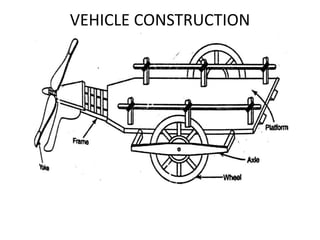

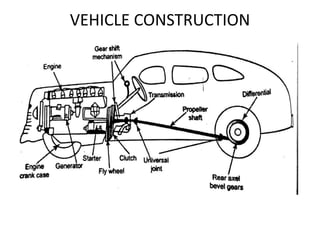

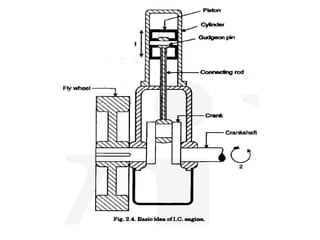

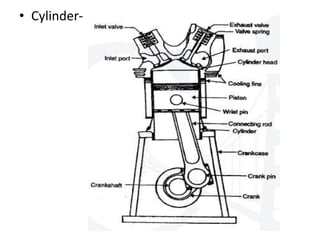

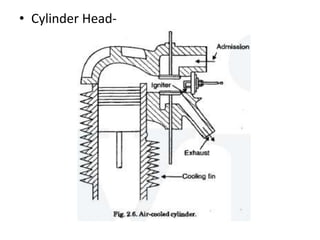

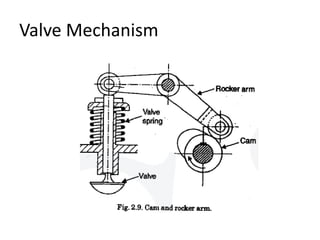

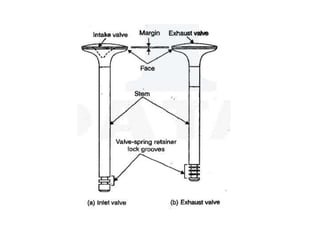

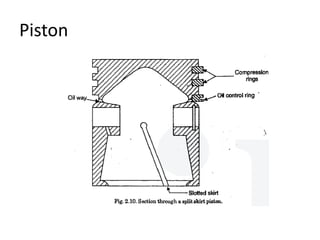

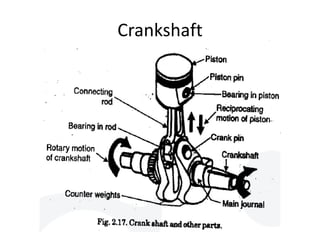

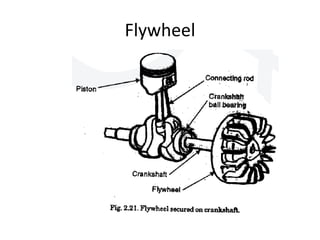

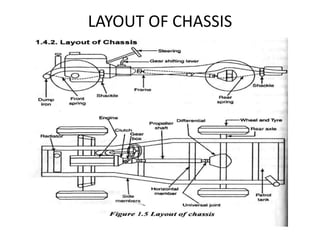

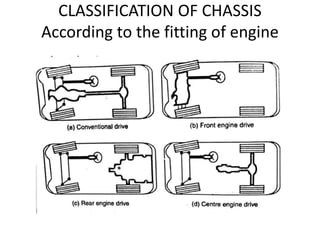

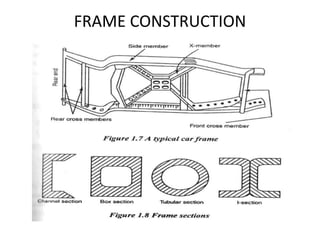

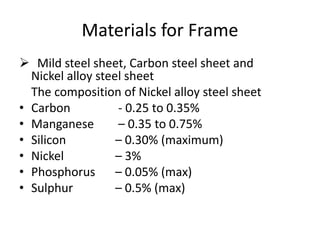

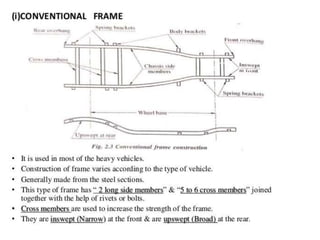

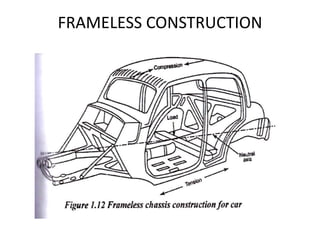

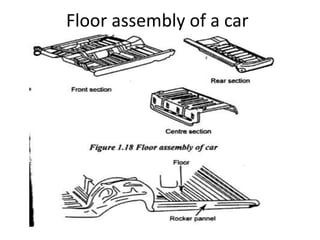

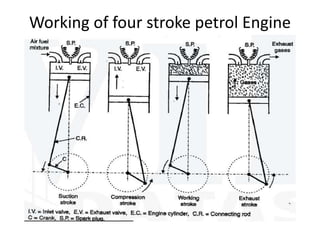

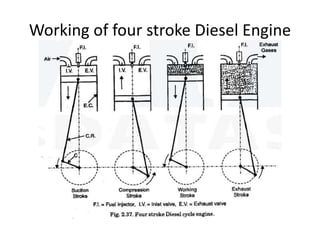

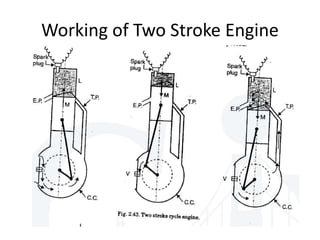

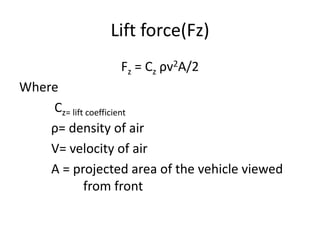

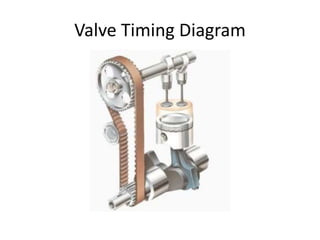

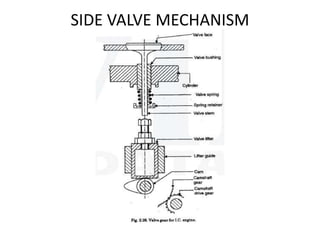

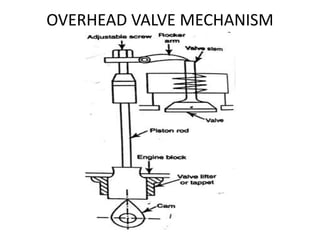

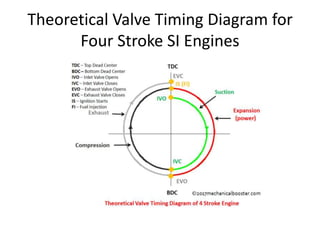

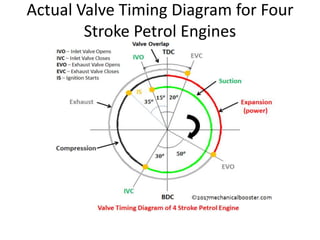

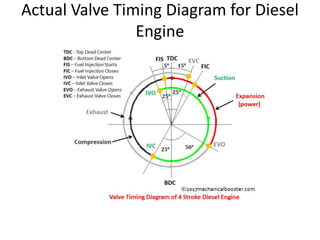

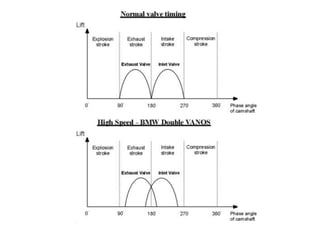

The document discusses vehicle structure and internal combustion engines. It describes the key components of an IC engine including the cylinder, piston, connecting rod, crankshaft, and flywheel. It also discusses the different parts of petrol and diesel engines. The document then covers vehicle construction and chassis components like the frame, suspension, steering, drivetrain, and wheels. It explains different types of frames and materials used. The working principles of 4-stroke petrol and diesel engines are covered along with the valve timing diagrams. Variable valve timing systems are also summarized.