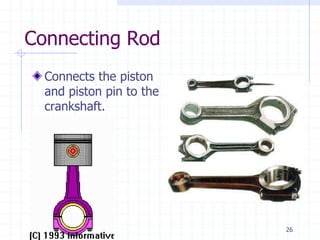

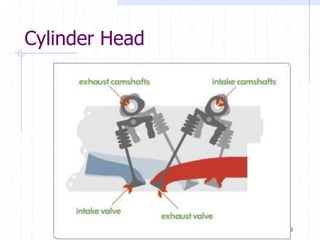

This document provides an overview of the course 191ME63 - Automobile Engineering I C Engine. It includes 5 units that will be covered: vehicle structure and engine components, energy sources, transmission systems and wheels/tyres, front axle/steering/brakes/suspension systems, and automotive electrical and electronic systems. The total periods for the course is 45. Key components of internal combustion engines are described such as the cylinder block, piston, connecting rod, crankshaft, cylinder head, valves, and camshaft. The 4-stroke engine cycle and engine cooling systems are also summarized.