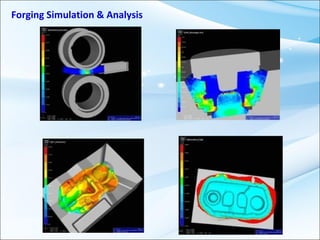

This document summarizes Varroc's manufacturing capabilities for undercarriage rollers and links. It describes Varroc's 2800 ton forging press line, hot forging facilities in Italy, heat treatment facilities in Aurangabad, roller machining facilities in Italy, tool room facilities, quality assurance facilities, engineering infrastructure including CAD/CAM/CAE and forging simulation software, and lists some client examples.