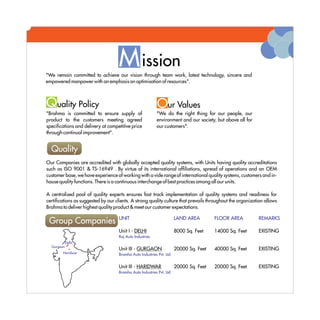

Raj Auto Group is a prominent player in the Indian automobile industry, founded by Mr. Rajeev Batra in 1989, focusing on indigenization and state-of-the-art manufacturing. The company is ISO 9001 and TS 16949 certified, specializing in a wide range of automotive components, including wiring harnesses and precision turned components, supported by advanced engineering and quality systems. They emphasize teamwork, technology, and resource optimization to ensure high-quality products and meet customer expectations.