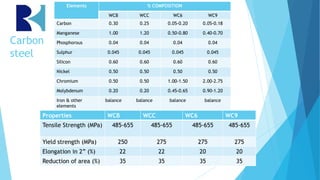

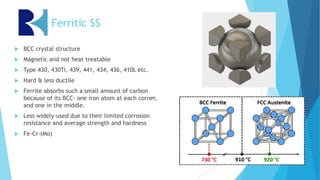

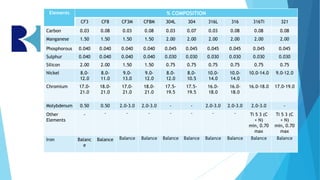

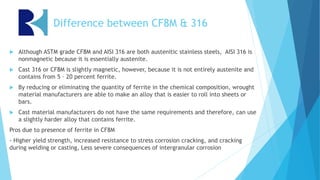

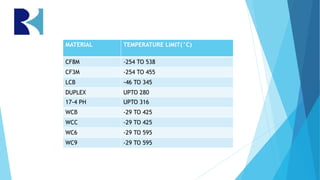

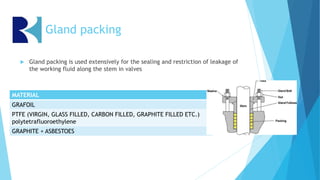

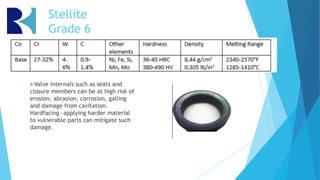

The document provides an overview of valve materials, including definitions, classifications, and properties of various metals and alloys used in valve construction. It details material specifications, packing materials, gasket types, and surface treatments, emphasizing the importance of certain elements in enhancing material qualities. Additionally, it covers the selection of bolting materials and gland packing for sealing in valve applications.