Embed presentation

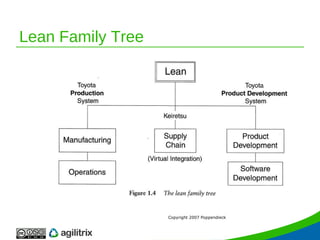

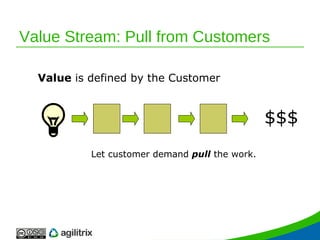

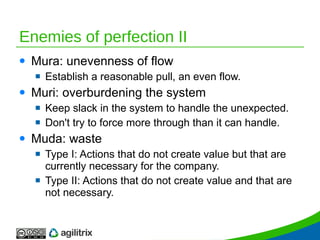

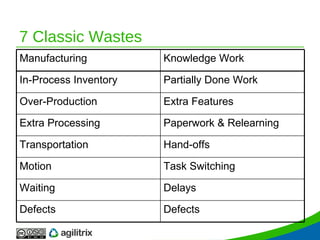

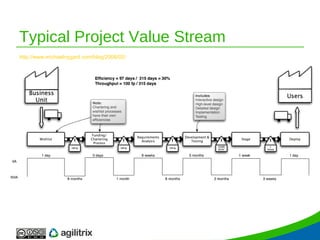

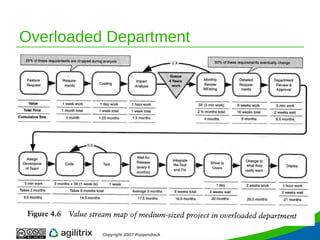

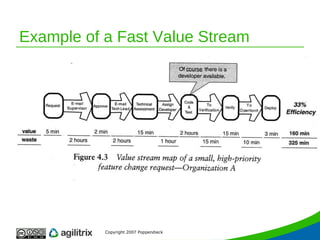

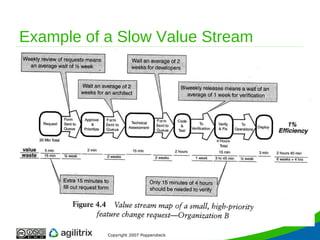

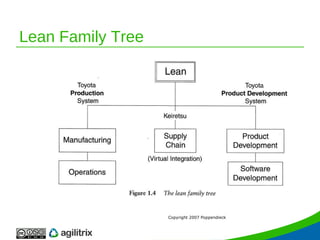

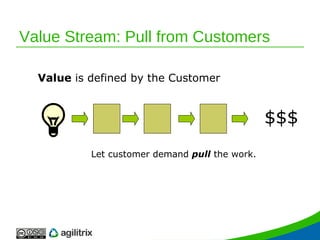

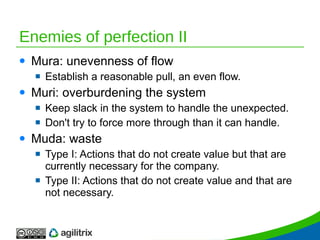

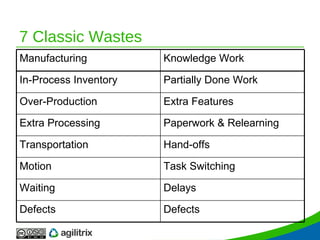

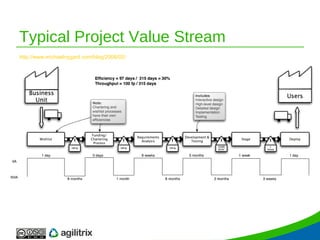

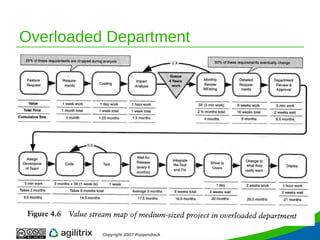

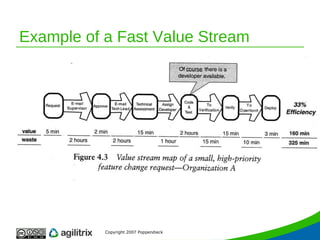

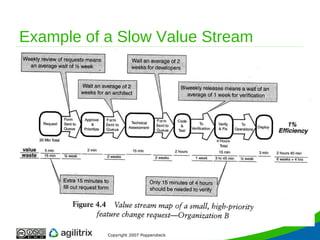

The document discusses lean principles focusing on value stream analysis, emphasizing customer-defined value and the importance of a pull system in production. It identifies three main enemies of perfection: waste, unevenness (mura), and overburden (muri), and outlines various types of waste in manufacturing and knowledge work. The content also includes practical exercises for analyzing value streams and understanding lean methodology.