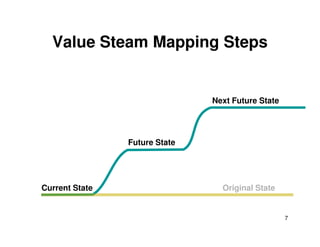

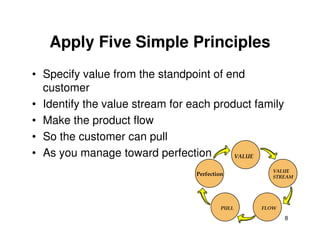

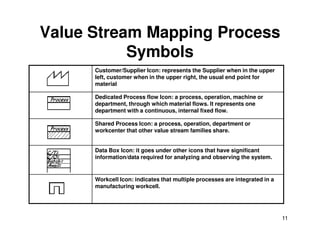

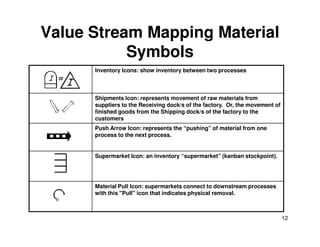

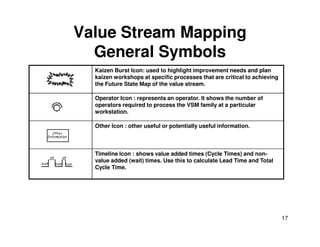

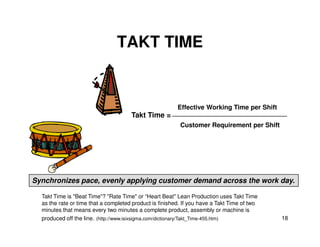

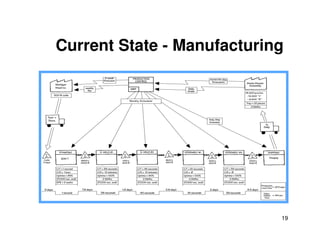

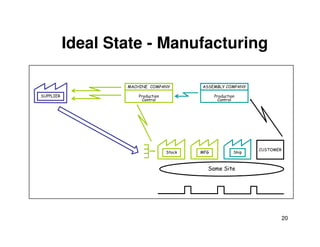

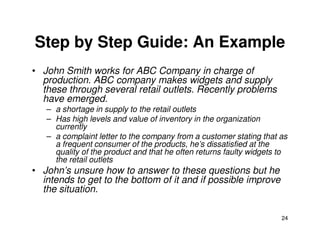

Value stream mapping (VSM) is a Lean tool used to analyze and improve the flow of materials and information needed to bring a product or service to a customer. The document discusses VSM techniques such as mapping the current and future states of processes, identifying value and waste, calculating takt time, and using various symbols to depict inventory levels, information flows, production controls and other elements. It provides step-by-step instructions for conducting a VSM including selecting a team and sponsor, choosing a process to map, collecting current state data, and developing a future state map to optimize process flow and eliminate waste.