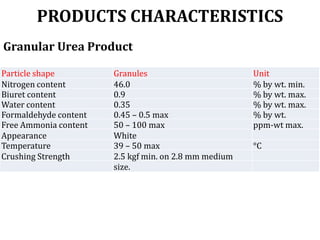

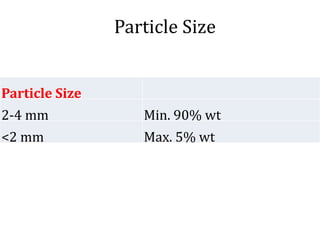

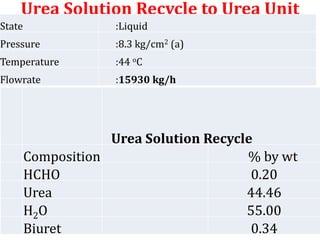

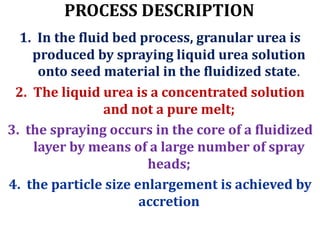

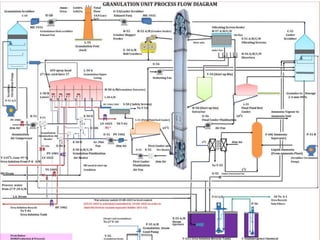

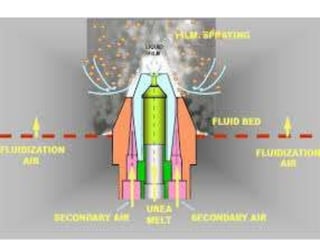

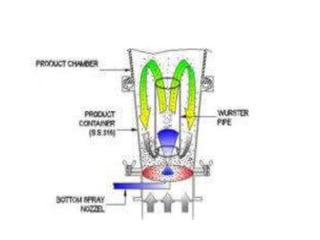

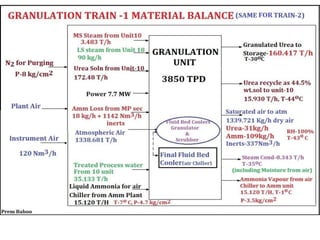

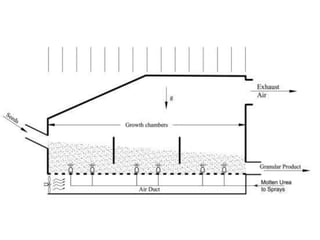

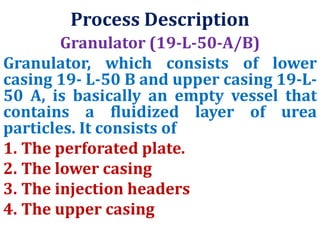

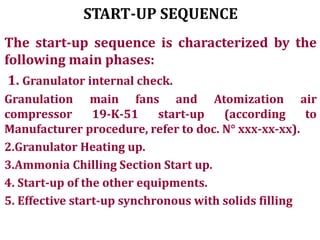

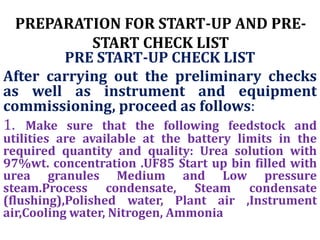

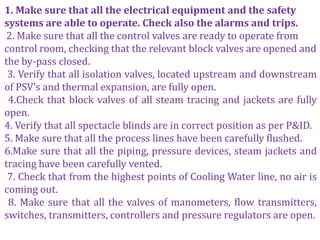

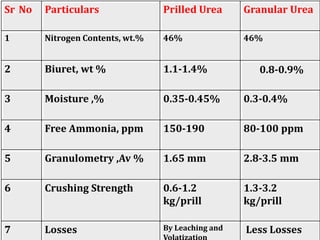

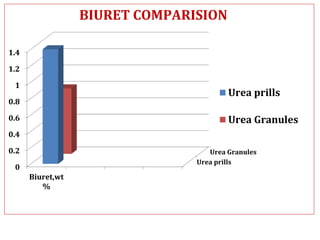

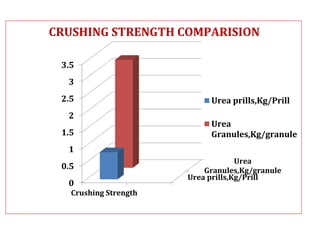

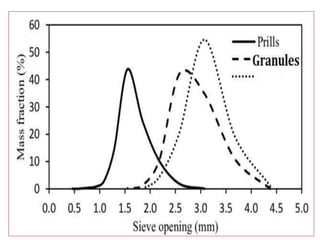

This document provides details on the urea granulation process. It describes the characteristics of granular urea including composition requirements. It outlines the granulation process which involves spraying liquid urea solution onto seed material in a fluidized bed. Key equipment involved includes the granulator, fluid bed coolers, screens, and conveying equipment. Startup and operating procedures are also summarized, focusing on gradually heating and preparing the granulator while maintaining proper process conditions.