Description of ammonia manufacturing processes

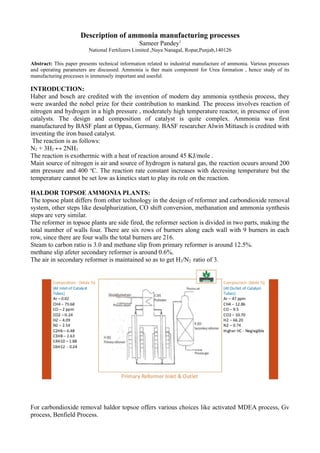

- 1. Description of ammonia manufacturing processes Sameer Pandey1 National Fertilizers Limited ,Naya Nanagal, Ropar,Punjab,140126 Abstract: This paper presents technical information related to industrial manufacture of ammonia. Various processes and operating parameters are discussed. Ammonia is ther main component for Urea formation , hence study of its manufacturing processes is immensely important and usesful. INTRODUCTION: Haber and bosch are credited with the invention of modern day ammonia synthesis process, they were awarded the nobel prize for their contribution to mankind. The process involves reaction of nitrogen and hydrogen in a high pressure , moderately high temperature reactor, in presence of iron catalysts. The design and composition of catalyst is quite complex. Ammonia was first manufactured by BASF plant at Oppau, Germany. BASF researcher Alwin Mittasch is credited with inventing the iron based catalyst. The reaction is as follows: N2 + 3H2 ↔ 2NH3 The reaction is exothermic with a heat of reaction around 45 KJ/mole . Main source of nitrogen is air and source of hydrogen is natural gas, the reaction ocuurs around 200 atm pressure and 400 o C. The reaction rate constant increases with decresing temperature but the temperature cannot be set low as kinetics start to play its role on the reaction. HALDOR TOPSOE AMMONIA PLANTS: The topsoe plant differs from other technology in the design of reformer and carbondioxide removal system, other steps like desulphurization, CO shift conversion, methanation and ammonia synthesis steps are very similar. The reformer in topsoe plants are side fired, the reformer section is divided in two parts, making the total number of walls four. There are six rows of burners along each wall with 9 burners in each row, since there are four walls the total burners are 216. Steam to carbon ratio is 3.0 and methane slip from primary reformer is around 12.5%. methane slip afeter secondary reformer is around 0.6%. The air in secondary reformer is maintained so as to get H2/N2 ratio of 3. For carbondioxide removal haldor topsoe offers various choices like activated MDEA process, Gv process, Benfield Process.

- 2. Uhde AMMONIA PROCESS: The primary reformer in this process is top fired and it may involve one or two synthesis converters, the main difference is in method used for carbon diocide removal. Uhde recommends use of activated OASE WHITE® (aMDEA® )licensed by BASF. This process combines both effects of physical and chemical absorption. The major design difference is use of two synthesis converters in order to maximise conversion. Large catalyst volume is used, the reactors consist of three beds, two in one reactor and other reactor of single bed, and radial flow is used. Uhde says the energy consumed is around 6.4 to 7.2 Gcal/MT ammonia. KELLOG BROWN AND ROOT AMMONIA PROCESS: The process involves cryogenic purification technology named KBR PURIFIER® to maintain H2/N2 ratio for synthesis of ammonia. The front end and Back end are thus independent of each other because of the purifier. Primiary reformer is top fired, with 3 bundles of tubes containing 44 tubes per bundle. Total four burner bundles are present with 14 burners in each burner. Additional 4 tunnel burner are present towards bottom of reformer, they maintain the tempreature of flue gas around 1000 o C for heat recovery and steam generation section. Steam to carbon ratio is around 2.8. The feature of using excess air in secondray reformer shifts the load from primary reformer thus increasing the life of tubes.

- 3. LINDE AMMONIA CONCEPT (LAC) PROCESS: The process uses natural gas or light hydrocarbons for production of ammonia, Gas purification system is PSA(pressure swing adsorption), no secondray reformer is present. Plant capacities upto 1350 MTPD have been installed using the concept. LAC uses Casale's ammonia radial flow converter. First plant was installed for GSFC gujrat in 1998. Source: https://www.linde-engineering.com/en/process_plants/hydrogen_and_synthesis_gas_plants/gas_products/ammonia/index.html The nitogen producing unit is separate, and nitrogen is added upstream of syngas compressor. ICI'S LEADING AMMONIA CONCEPT(LCA) PROCESS: Imperial chemical industries started two identical plants based on LCA process in 1988. The plant is divided in two plants, the core plant and the utilities plant. Core plant uses gas heated reactor and s/c ratio is around 2.5 . Primary reformer is heated by the gas exiting secondary reformer. Use of isothermal shift converter eliminates fisher-tropsch reaction. Ammonia reactor is based on ICIC's cobalt catalyst. Pressure in synthesis reactor is around 80 ata.

- 4. This process is not in so ,much use nowadays.