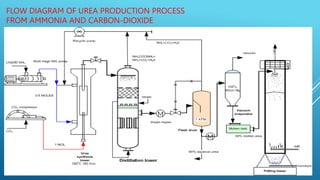

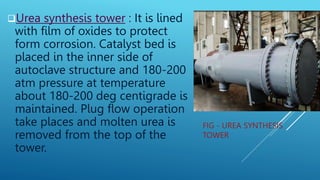

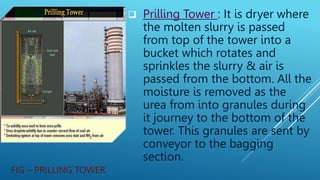

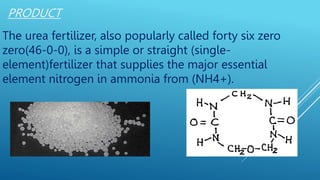

The document presents a study on Shahjalal Fertilizer Factory Ltd., established on July 1, 2011, with an annual production capacity of 580,800 metric tons of urea from natural gas. The urea production process involves reacting ammonia and carbon dioxide under high temperature and pressure, followed by various stages including distillation and prilling to produce the final fertilizer product. Urea fertilizer, known as 46-0-0, enhances soil fertility and promotes crop growth.

![PRESENTED BY

1.Hosainur Rahman Aungon[Roll-1511007]

2.Razib Hossen[Roll-1511008]

3.Abid Hasan Badhon[Roll-1511009]](https://image.slidesharecdn.com/studyonafertilizerindustry1-240505051009-96bb298a/85/A-Case-Study-on-Fertilizer-Industry-by-RUET-3-320.jpg)