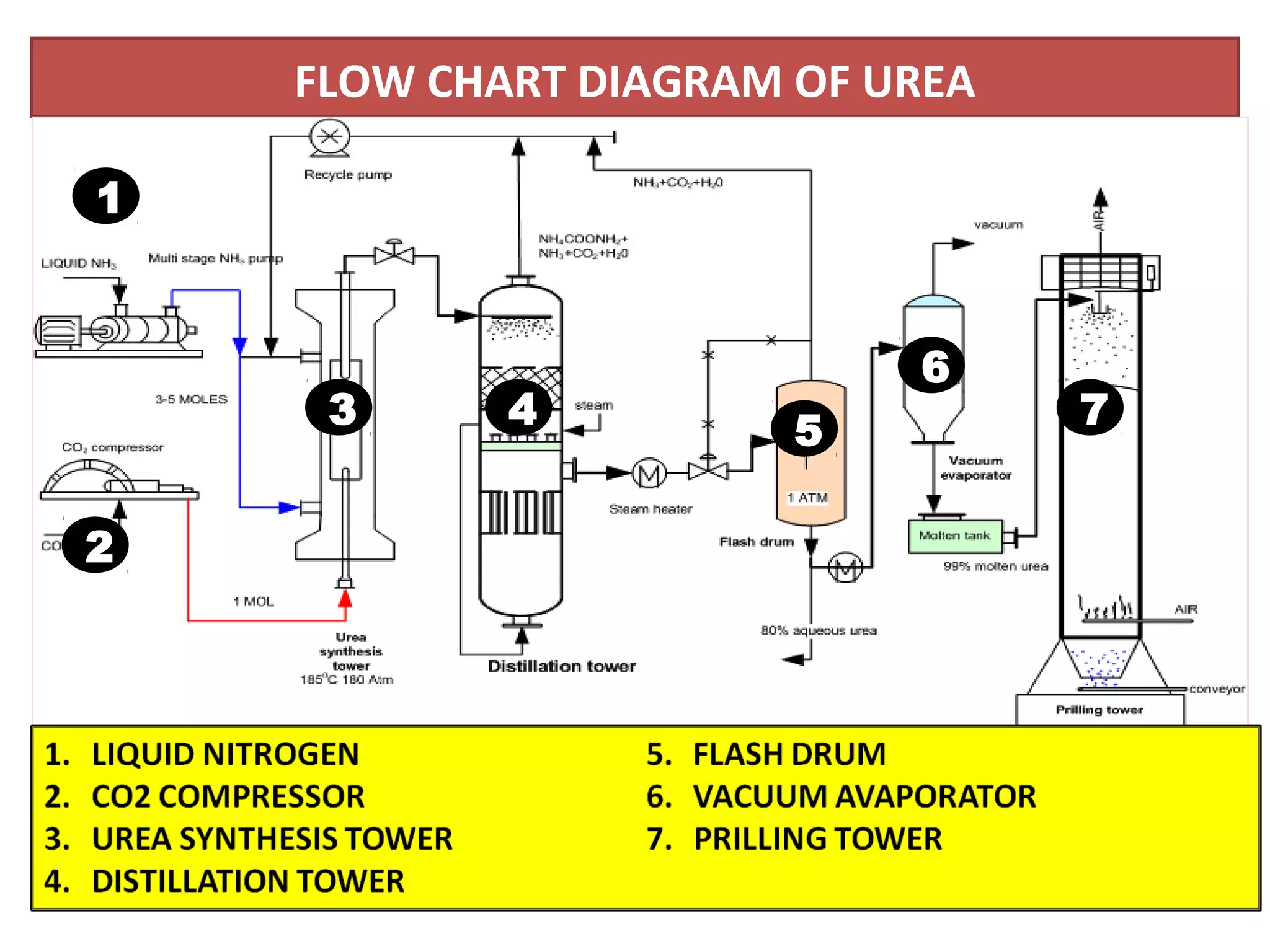

Synthetic fertilizers are produced via a multi-step process. Ammonia is first produced from natural gas and air, then combined with carbon dioxide to form urea in a high-pressure tower. The urea solution is concentrated, sprayed into a prilling tower to form granules, then bagged. Nitric acid is made by reacting ammonia and air over a catalyst. It is mixed with ammonia to create ammonium nitrate, an important nitrogen fertilizer component. The document outlines the key industrial processes used to synthesize common nitrogen-based fertilizers from basic feedstocks.