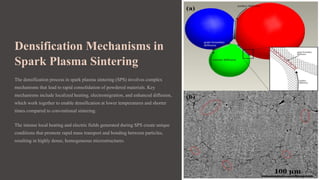

The document discusses spark plasma sintering (SPS), an advanced materials processing technique that utilizes pulsed electric current and pressure to rapidly sinter powdered materials, producing unique microstructures and enhanced properties. It details the principles, advantages, and applications of SPS for ceramics and metals, emphasizing its energy efficiency and capabilities for precise microstructural control. Challenges in scaling up and controlling the process for industrial applications and future developments in material exploration are also outlined.