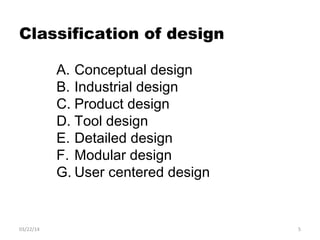

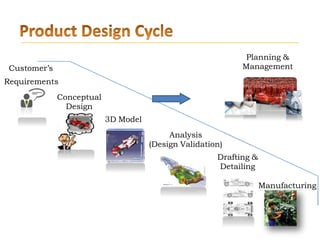

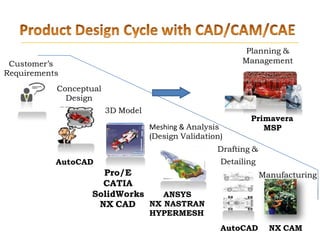

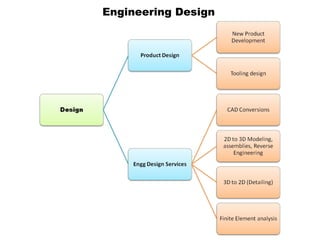

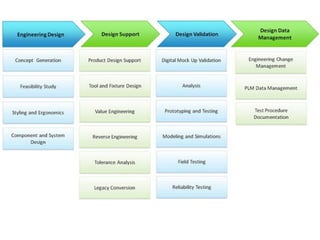

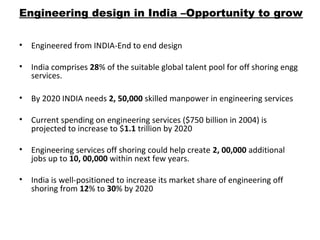

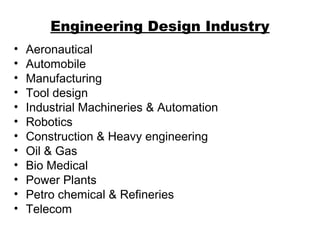

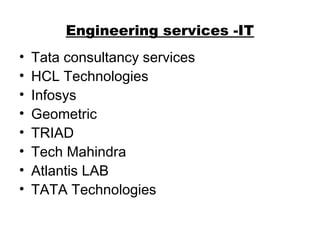

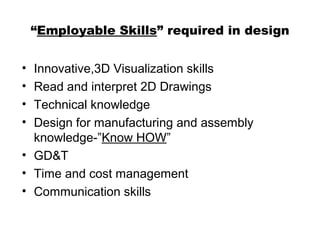

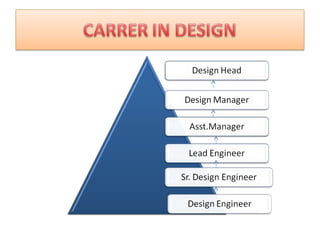

The document provides an overview of career opportunities in engineering design and services. It discusses the engineering design process, types of engineering design including conceptual design, product design, and detailed design. It also outlines the major industries served by engineering design such as automotive, manufacturing, aerospace, and more. Additionally, it lists some of the top engineering design software tools used like SolidWorks, CATIA, Creo, ANSYS, and key skills required for those seeking employment in this field.