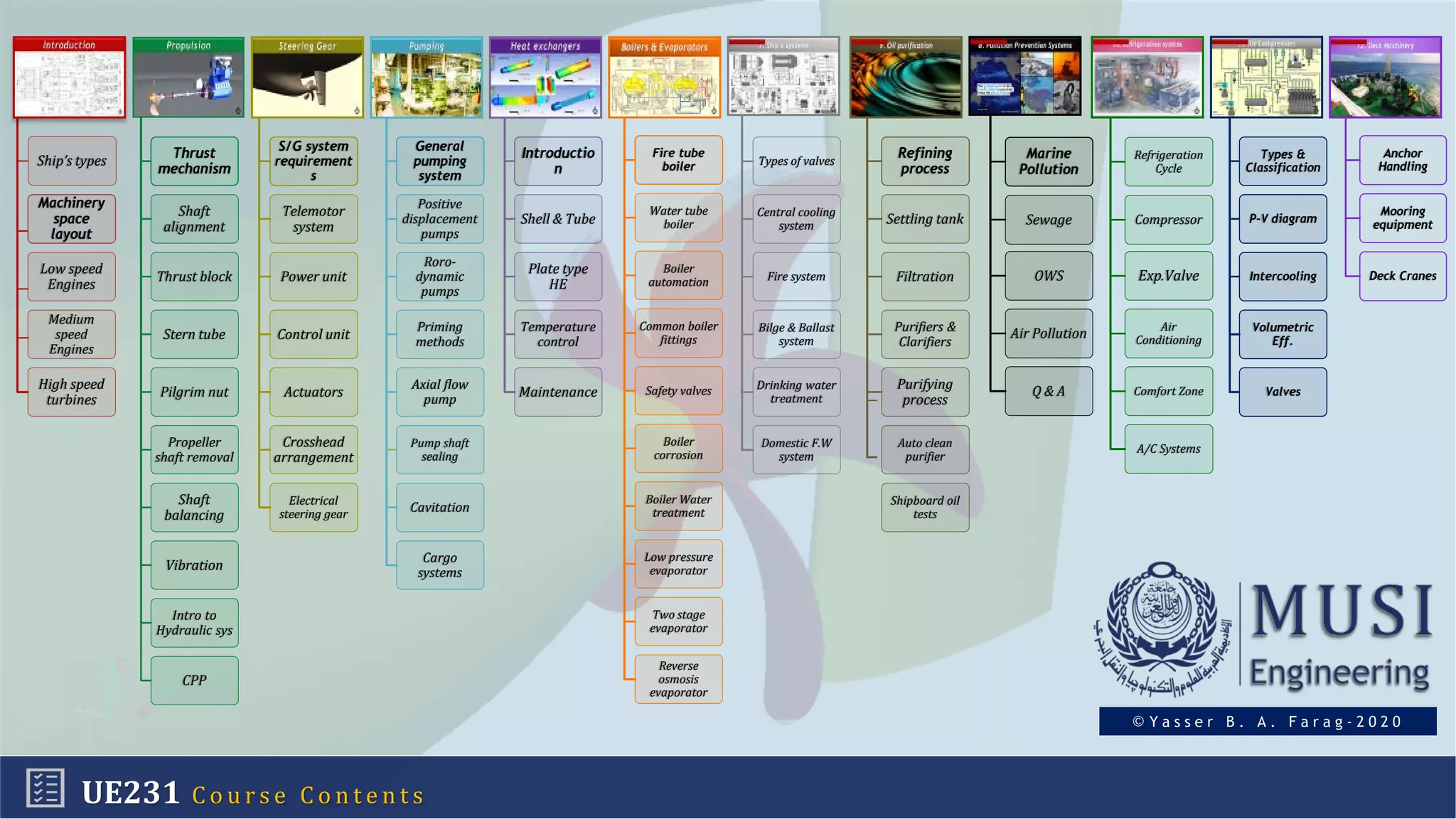

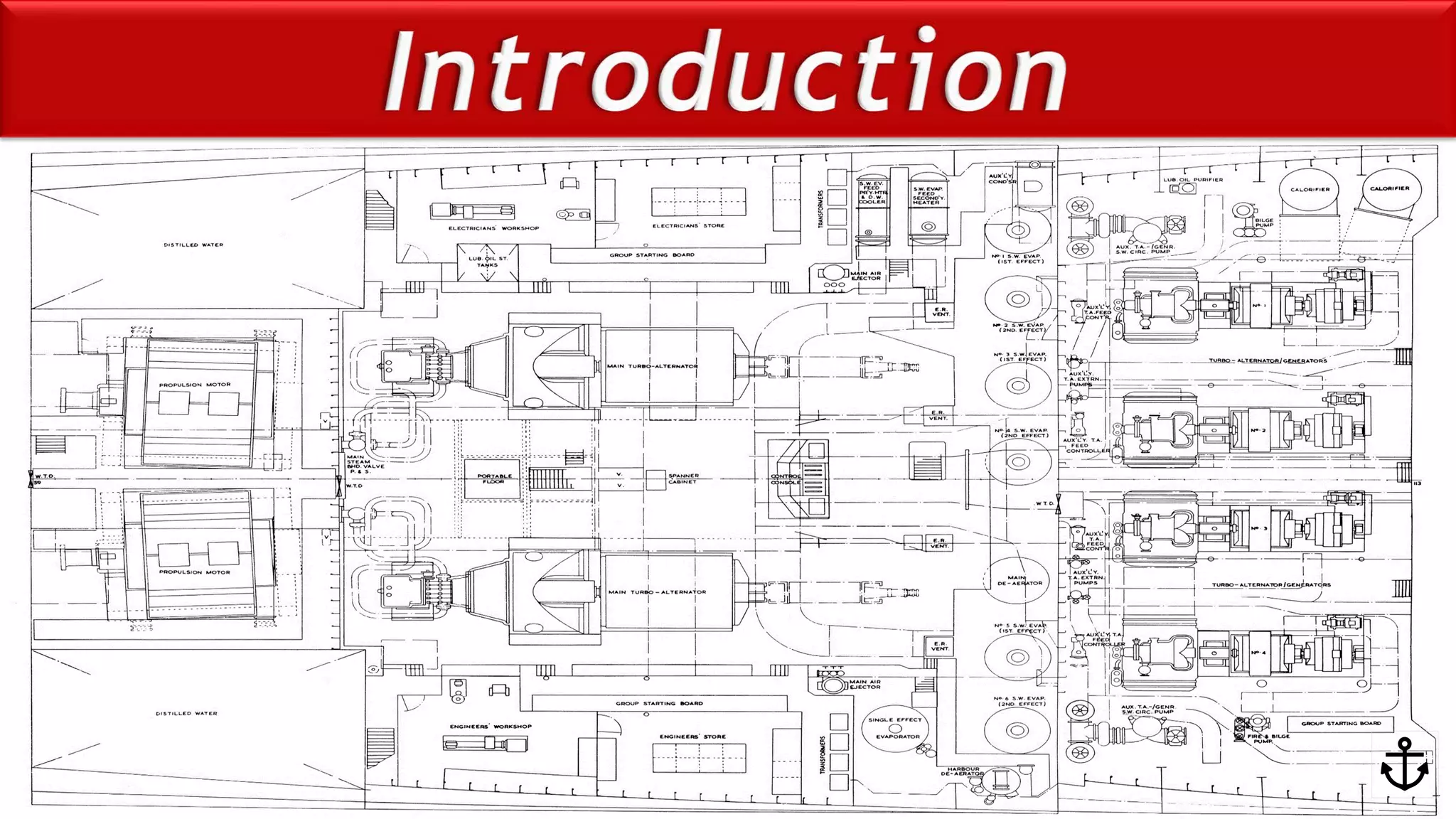

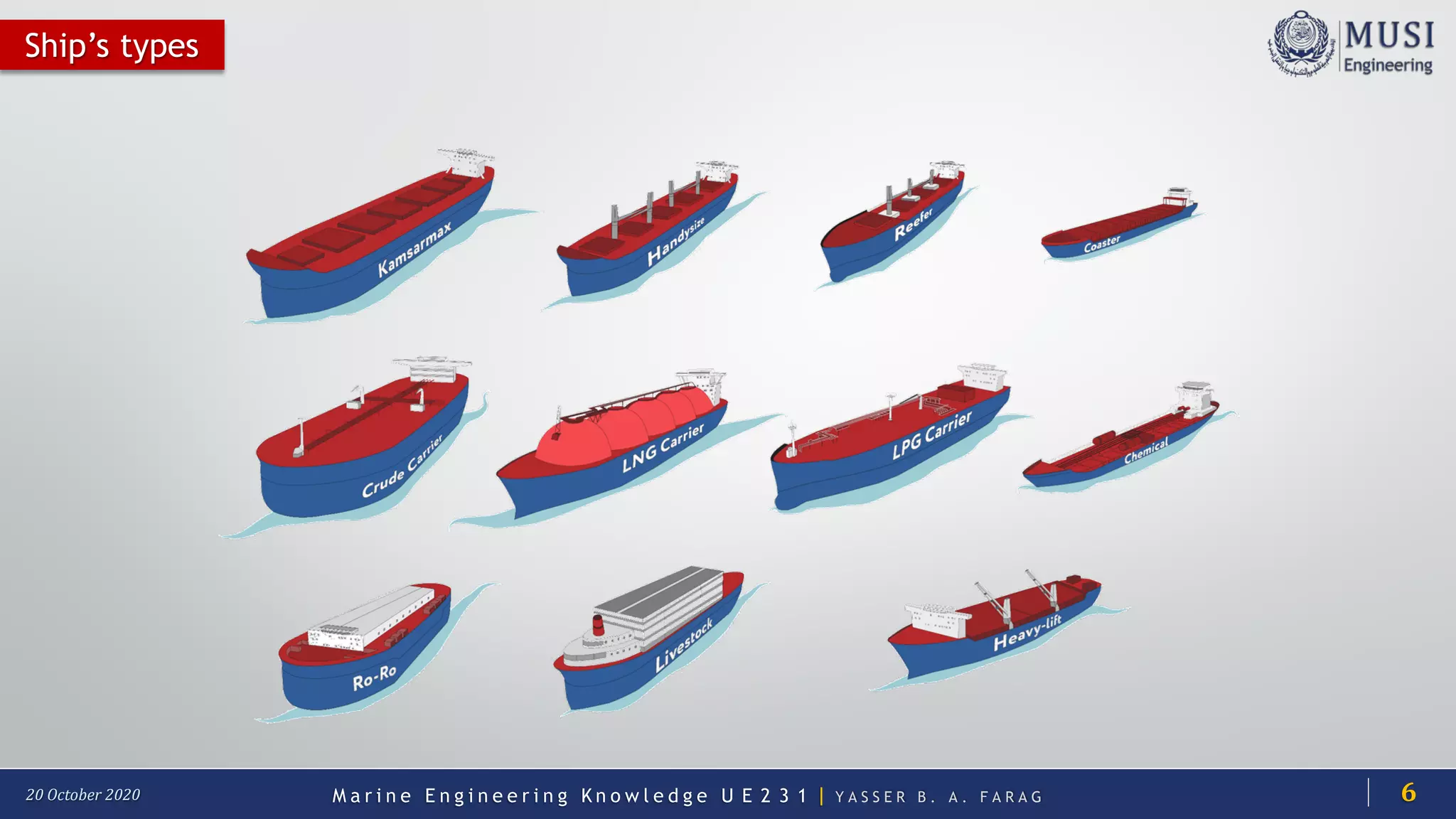

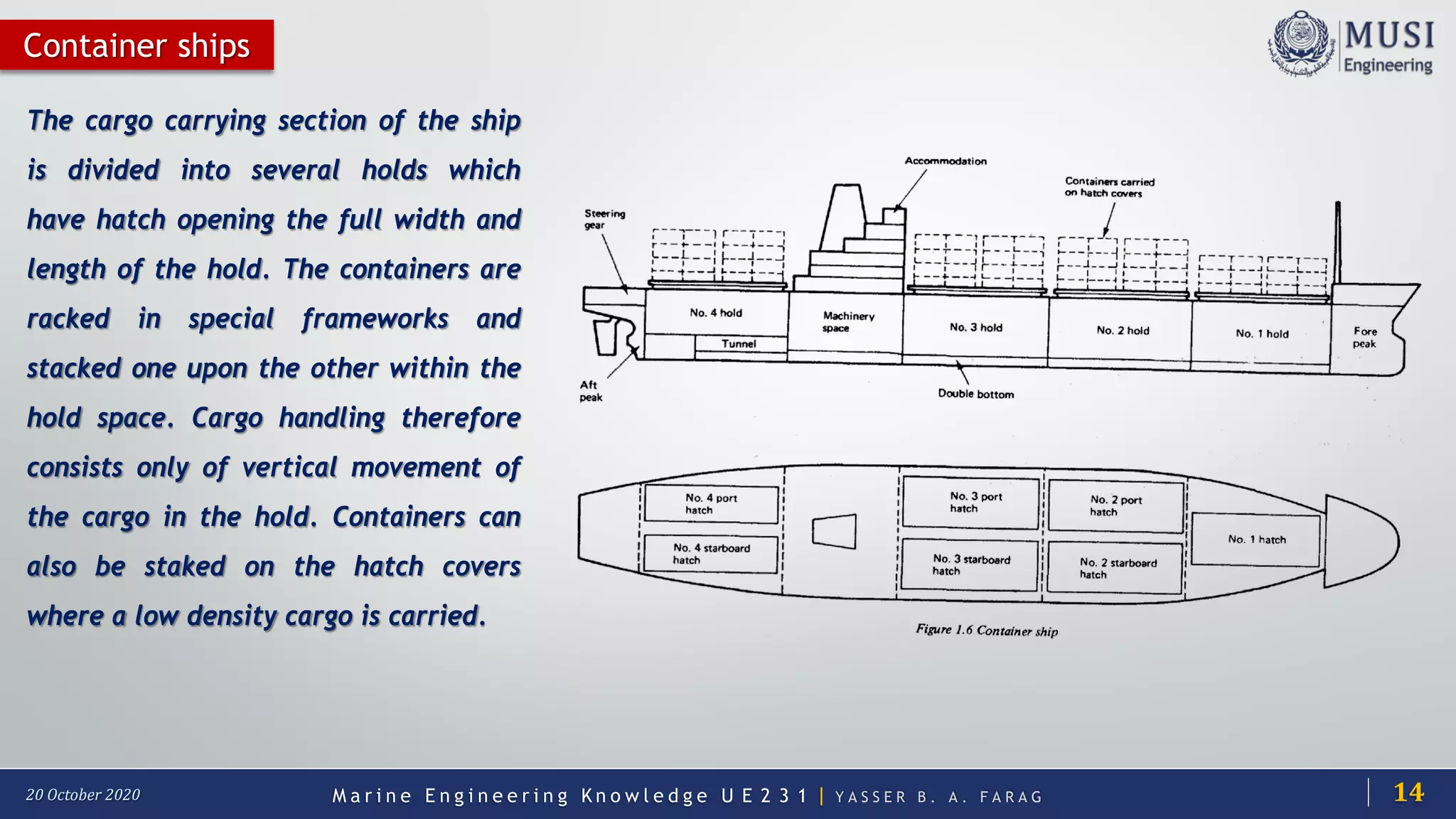

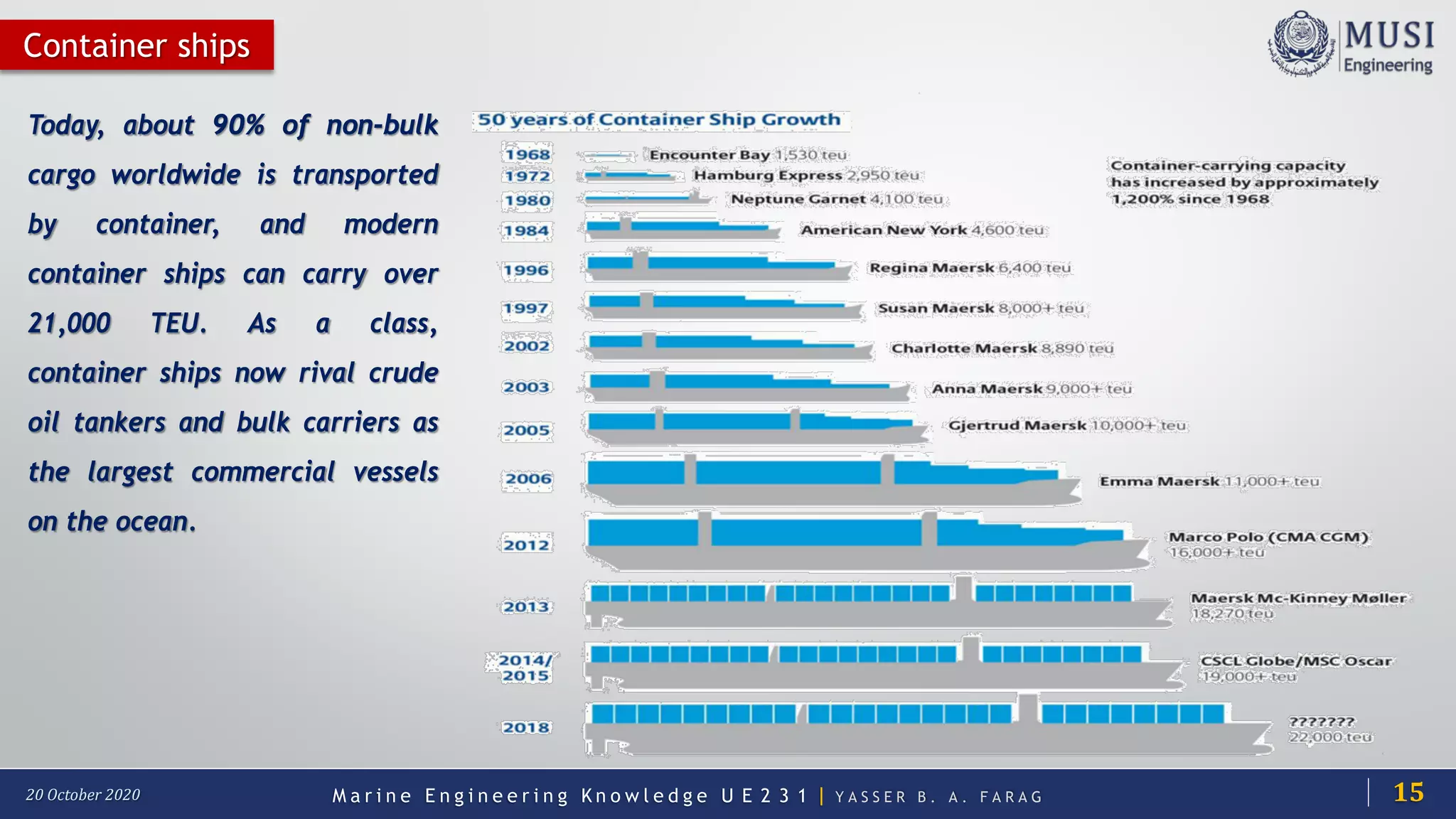

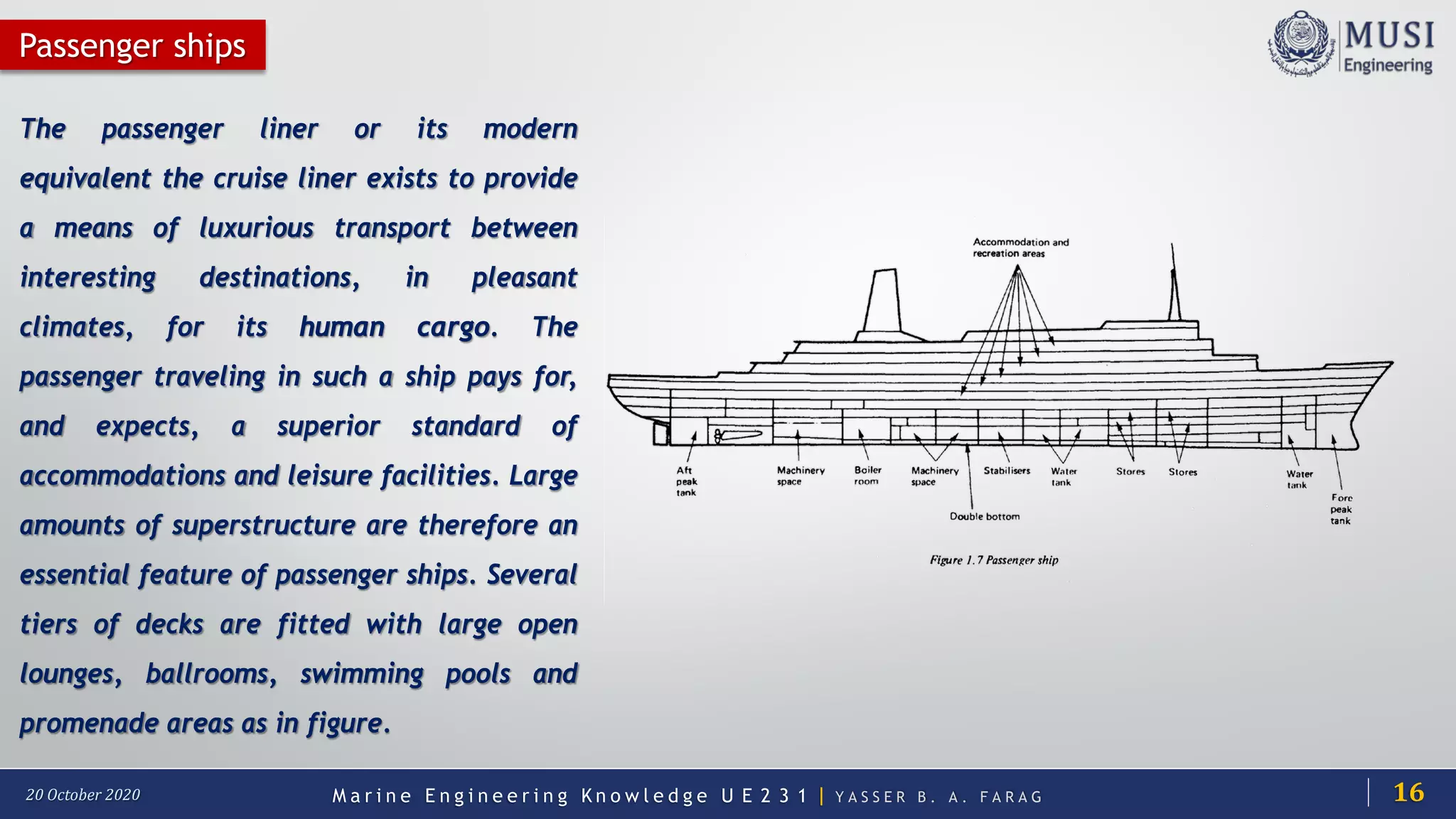

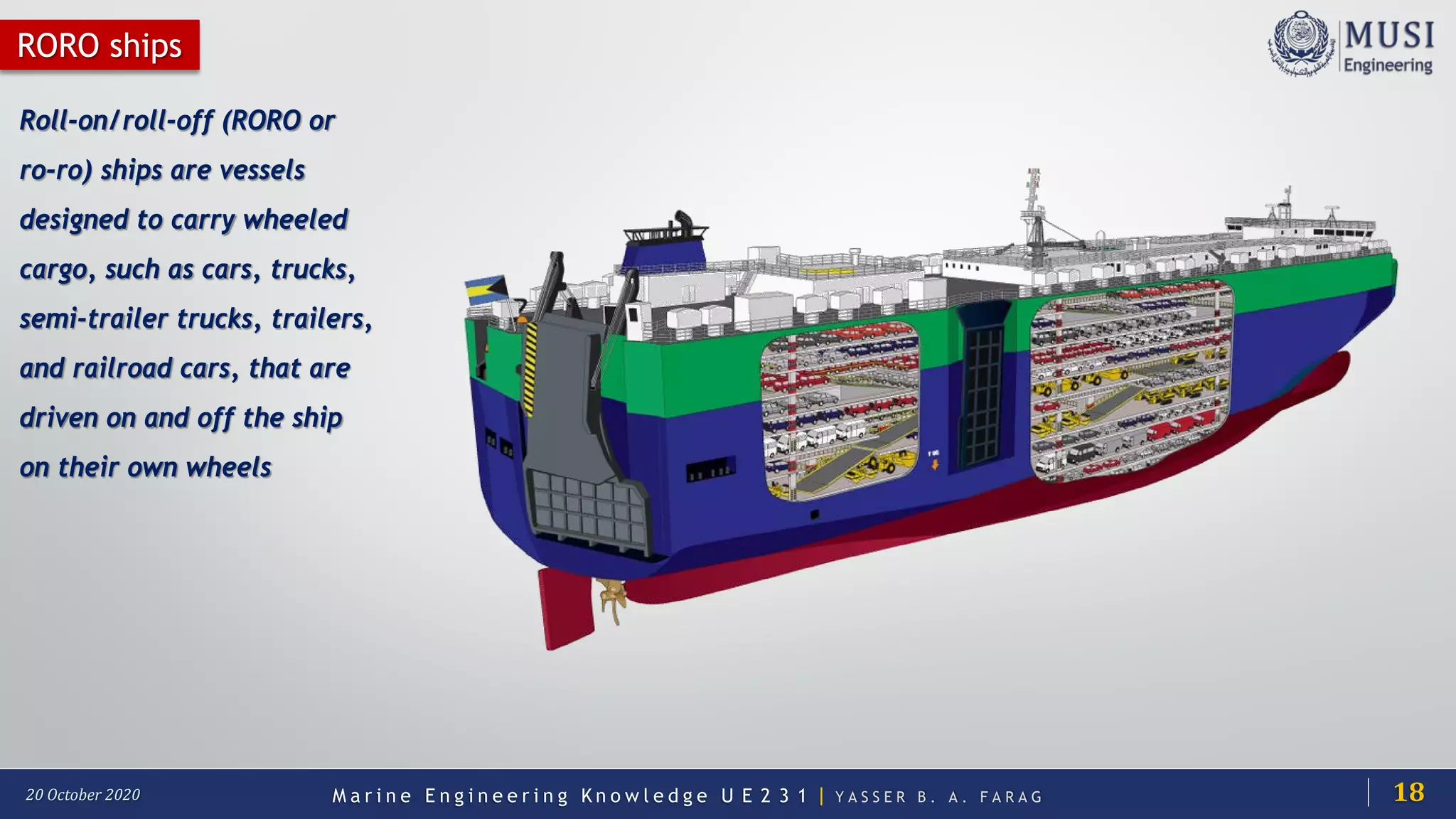

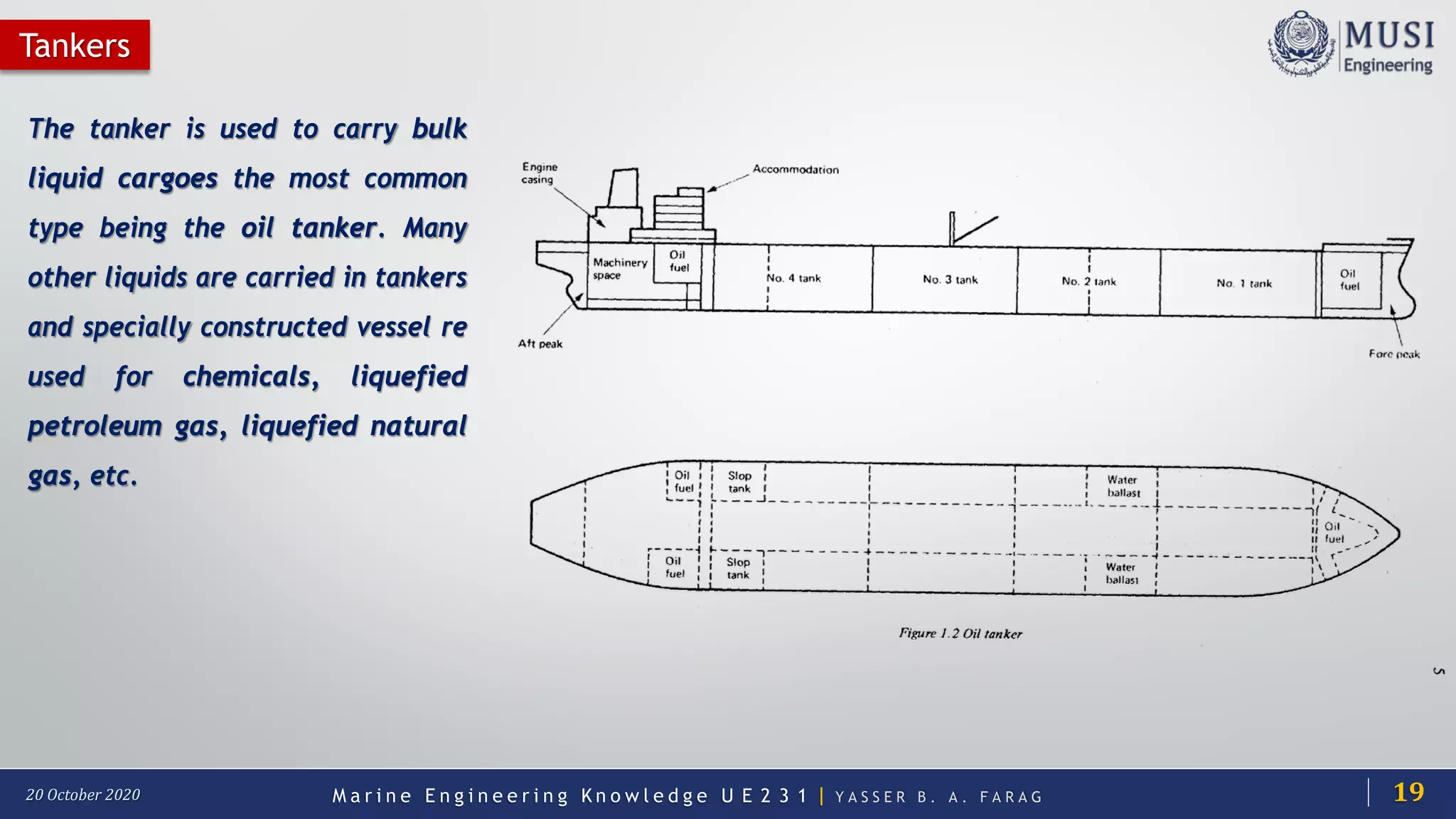

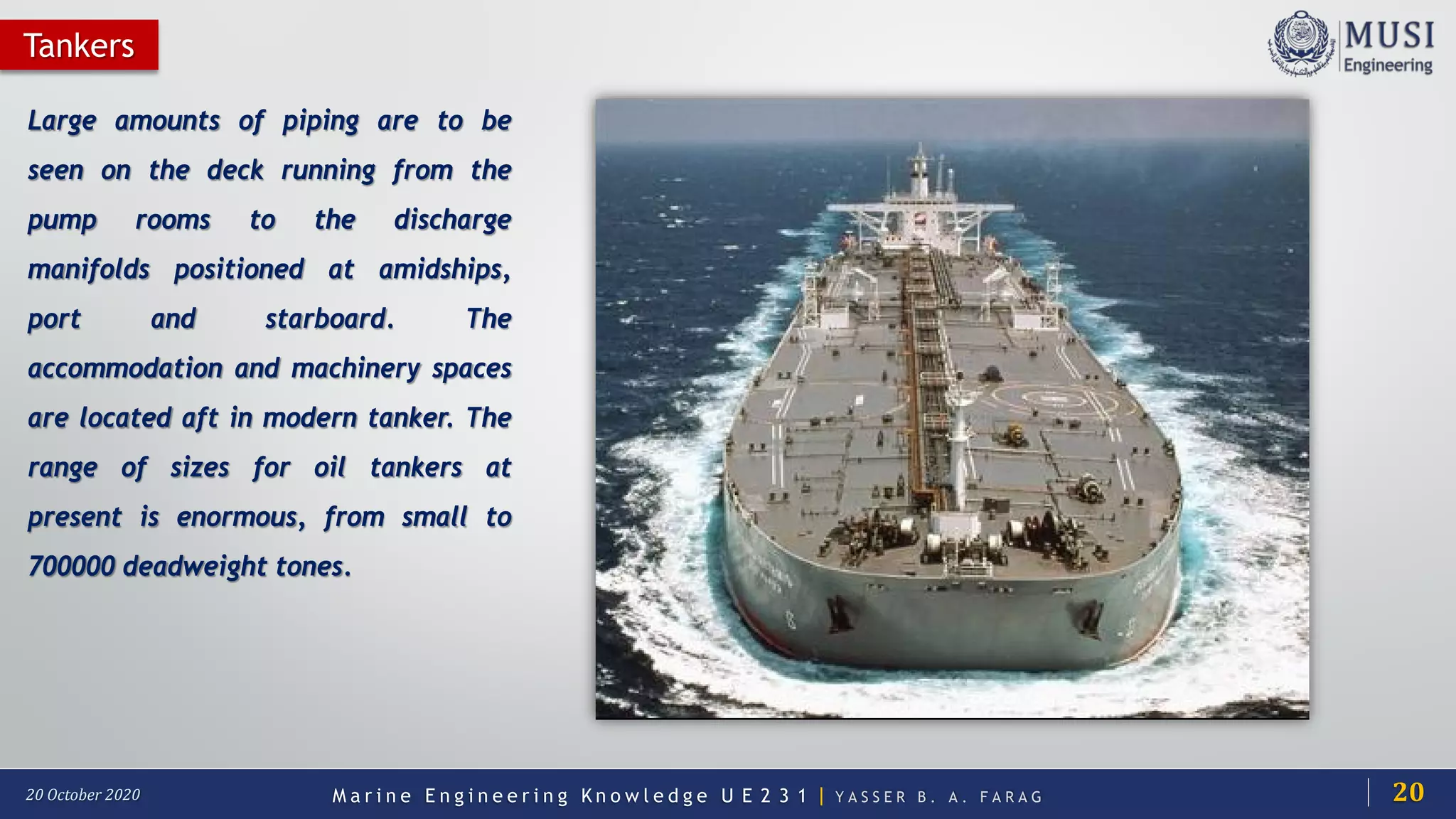

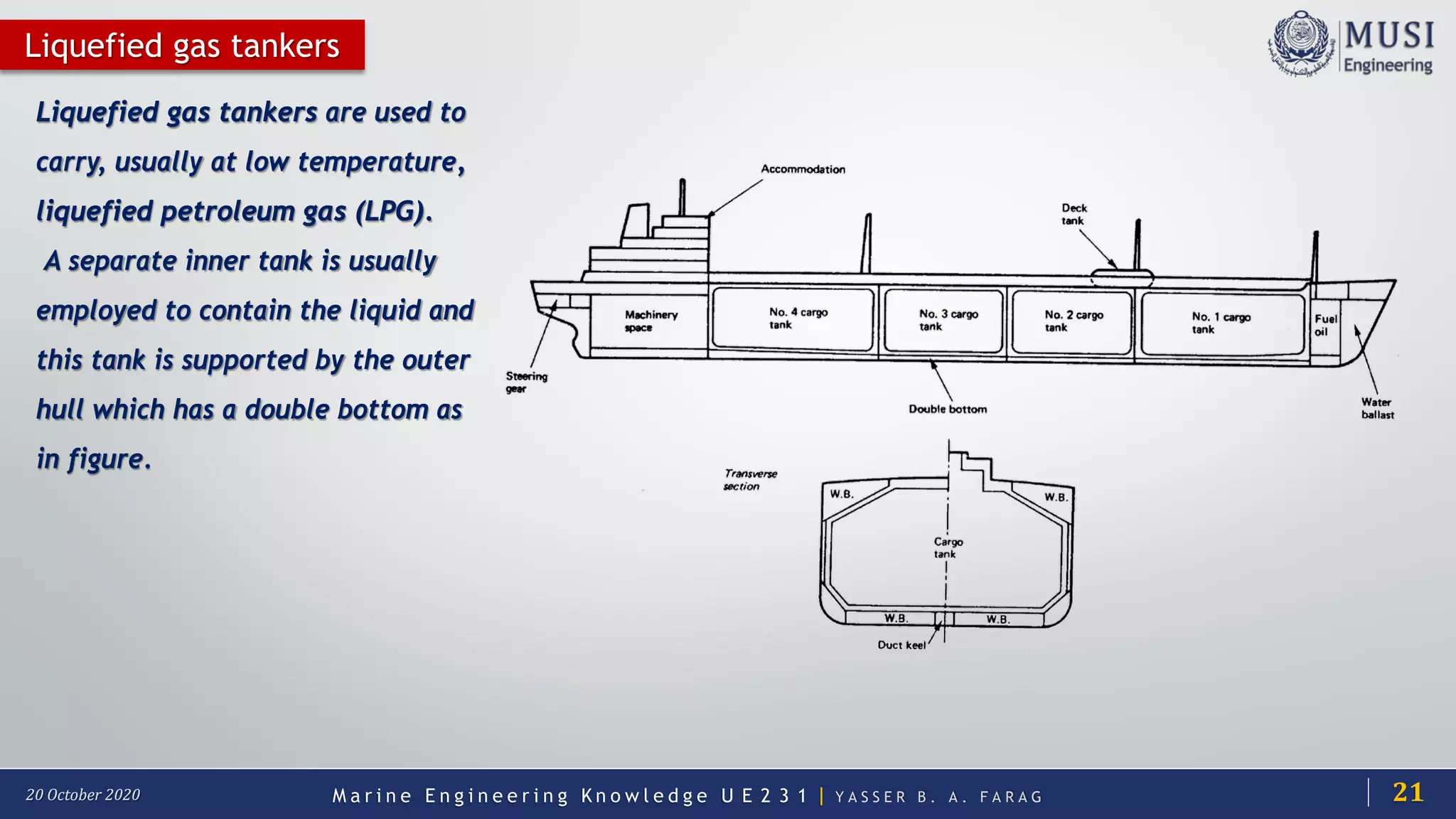

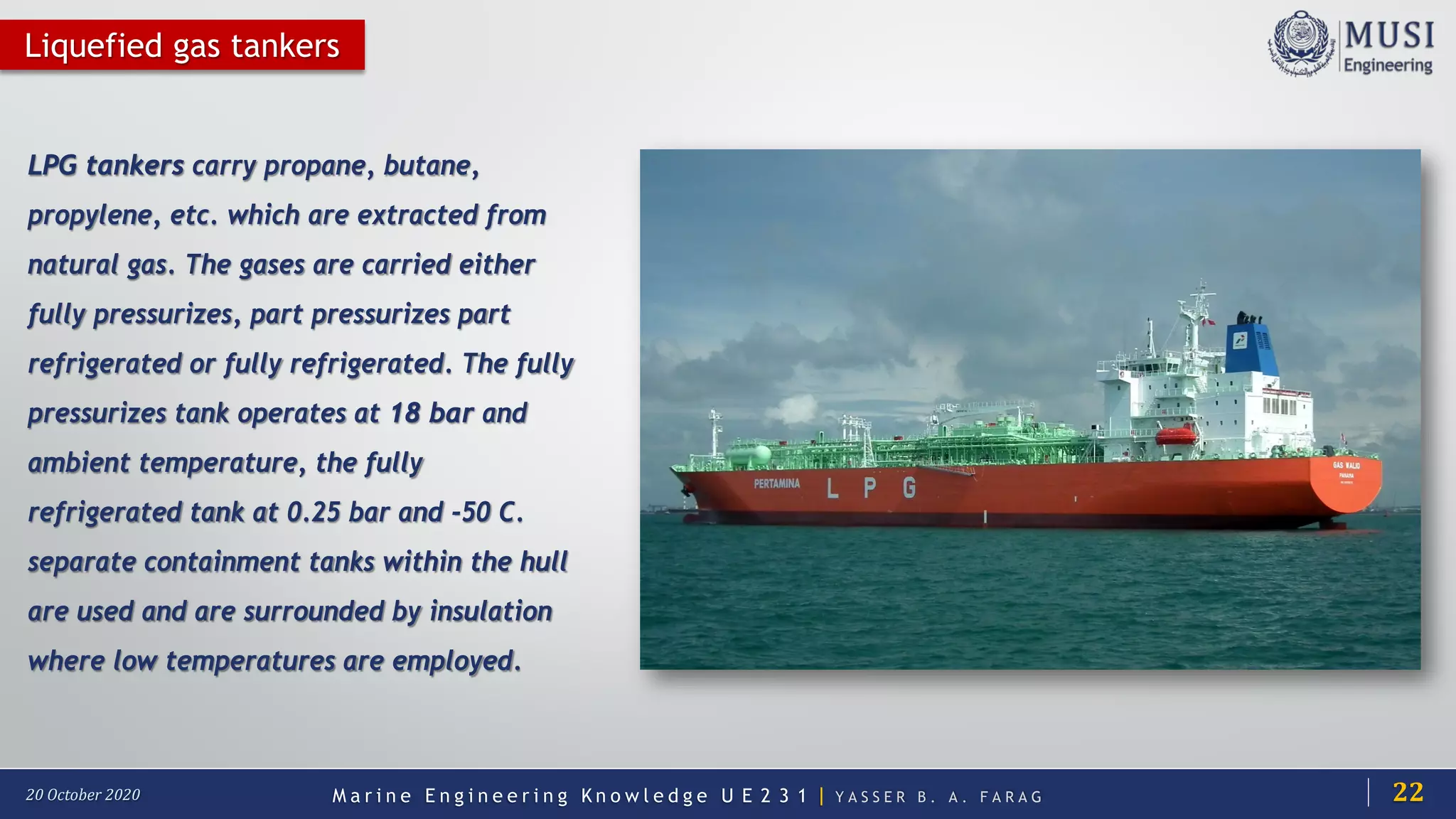

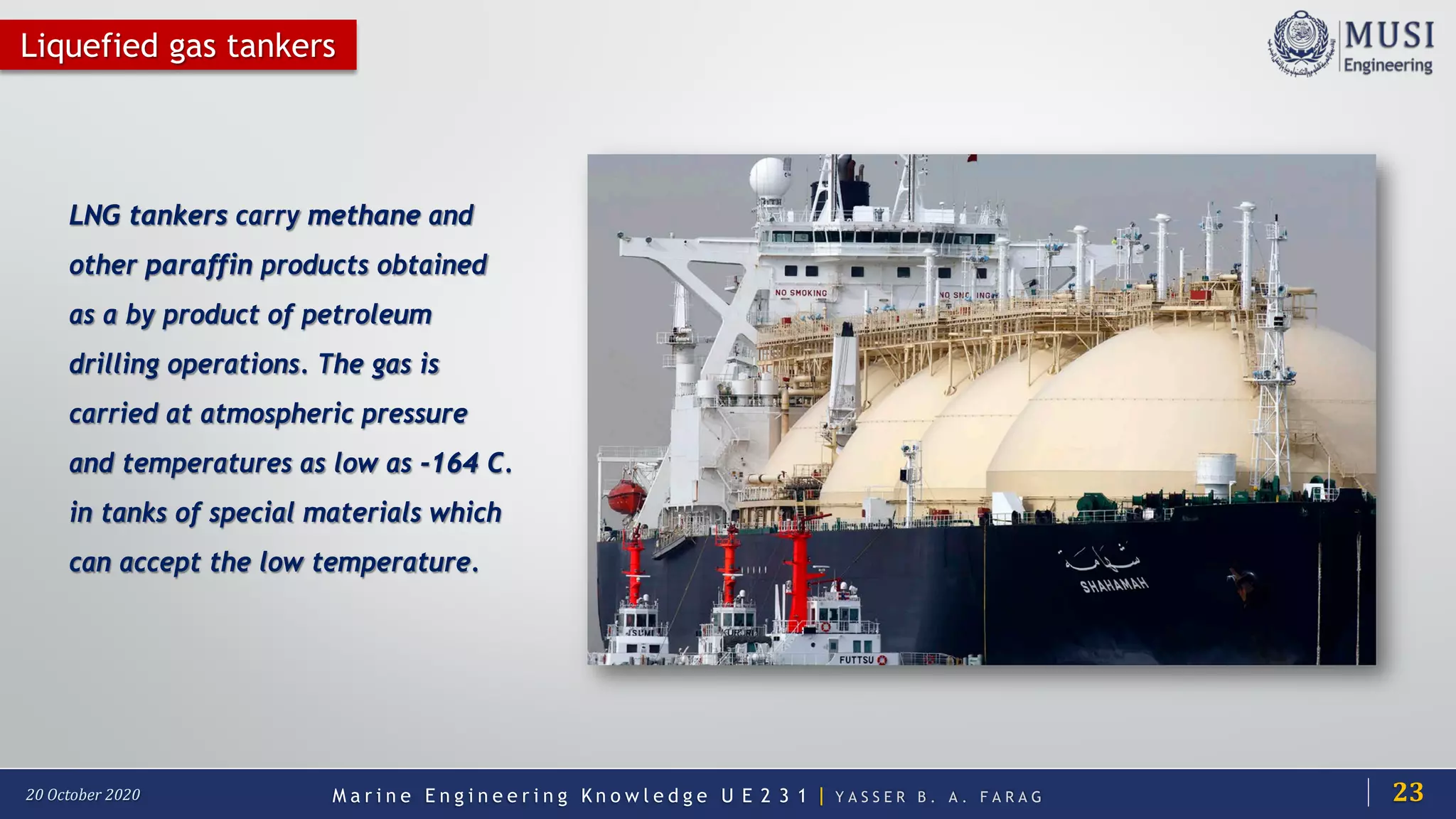

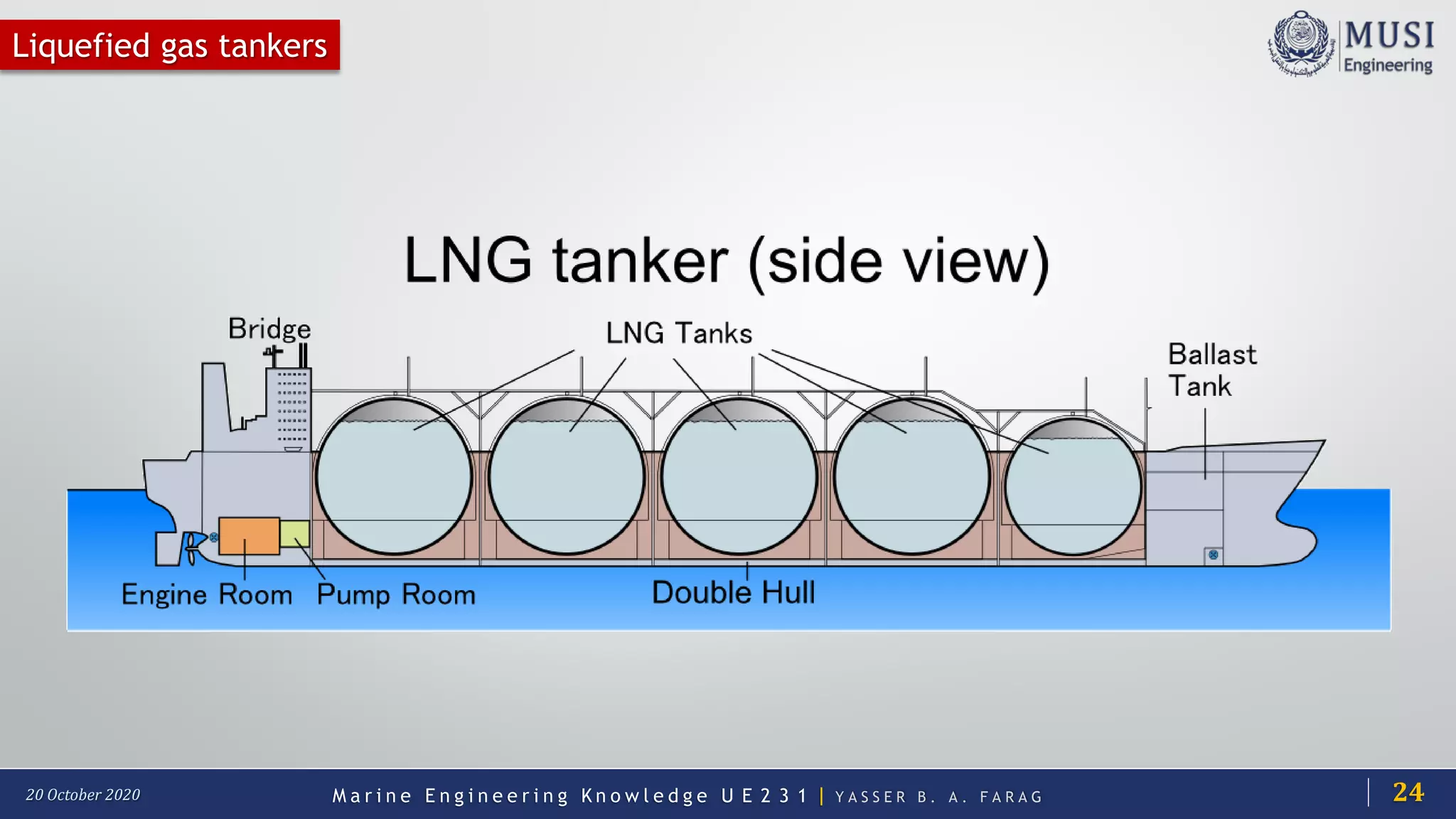

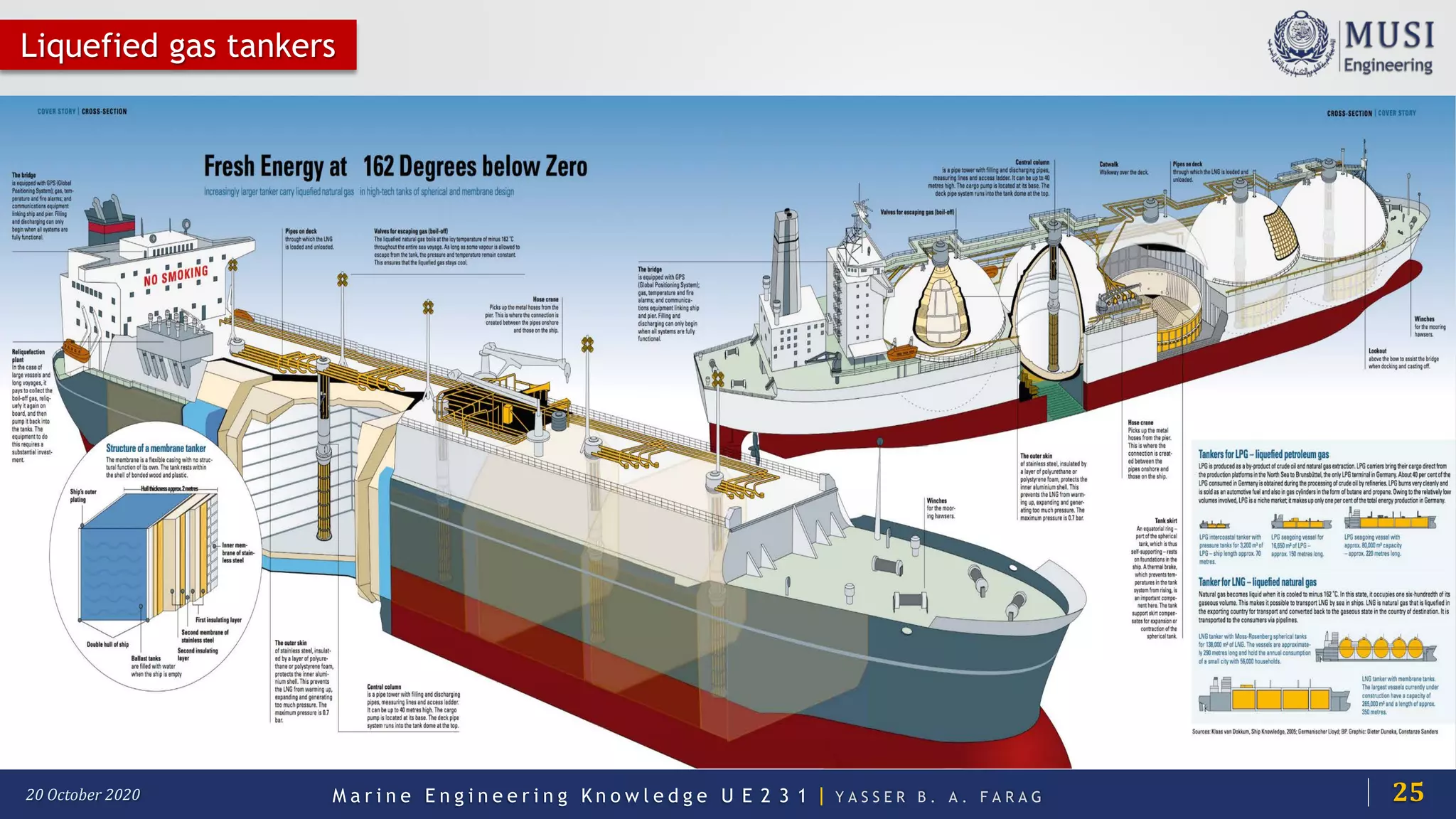

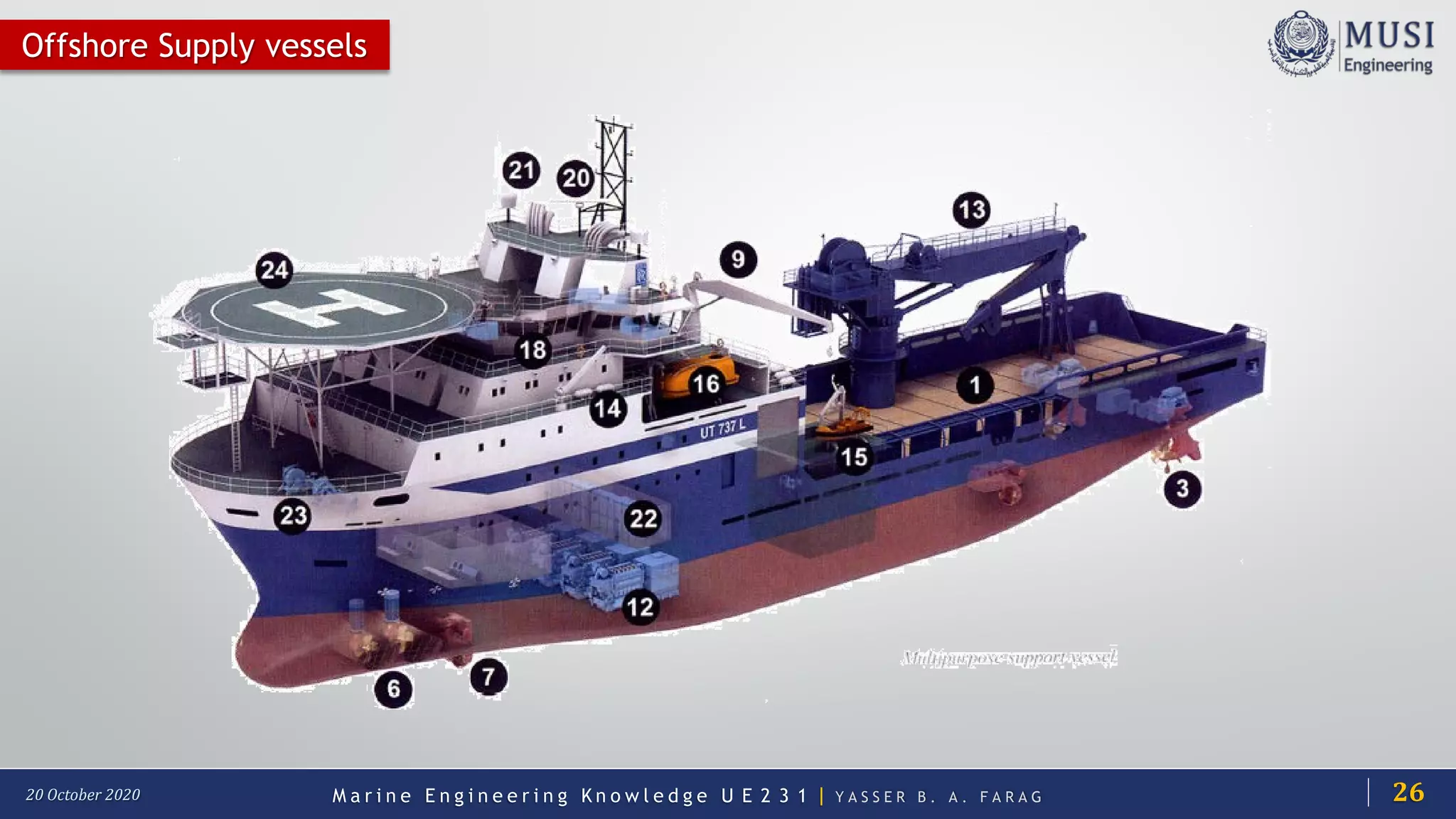

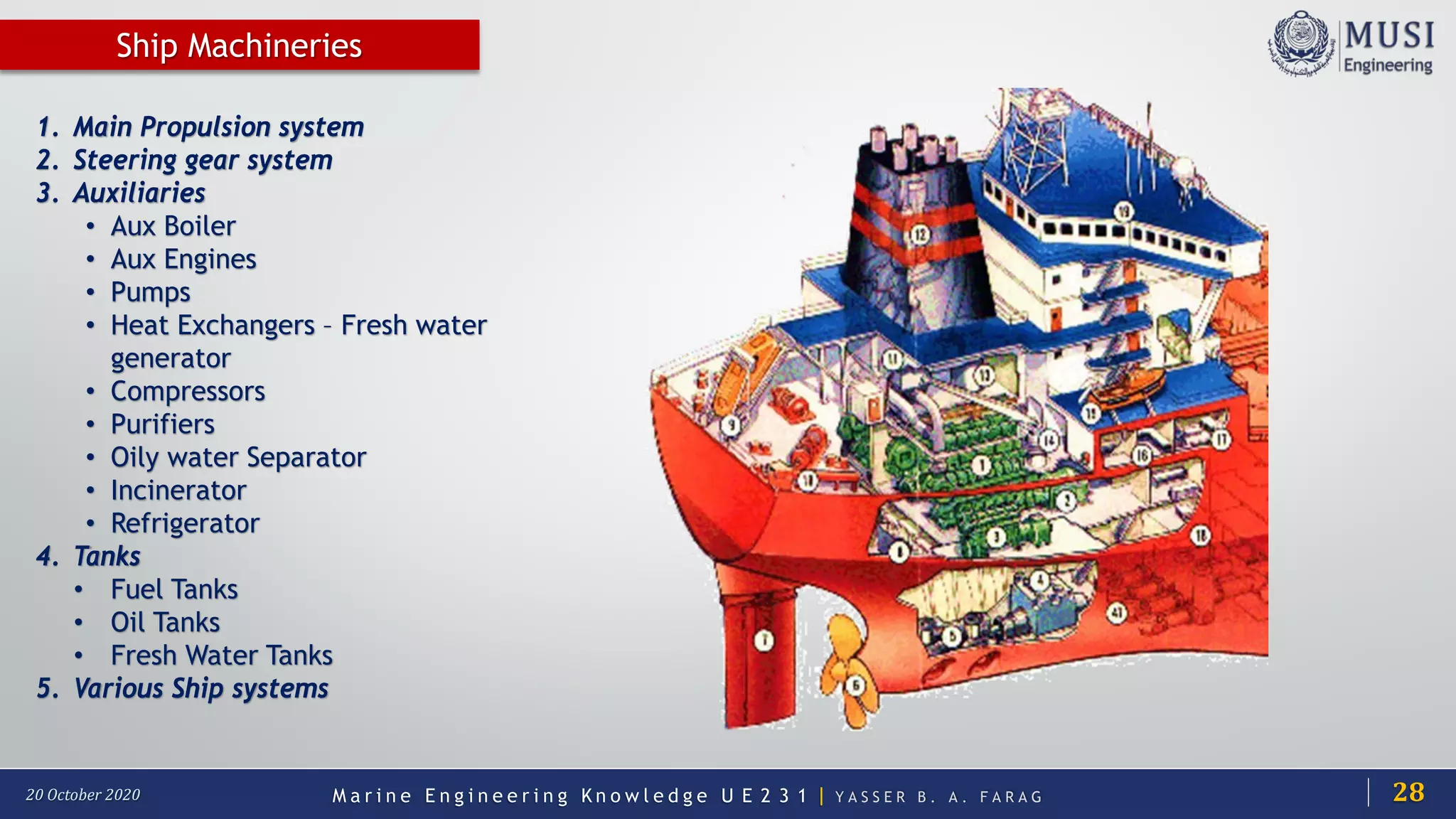

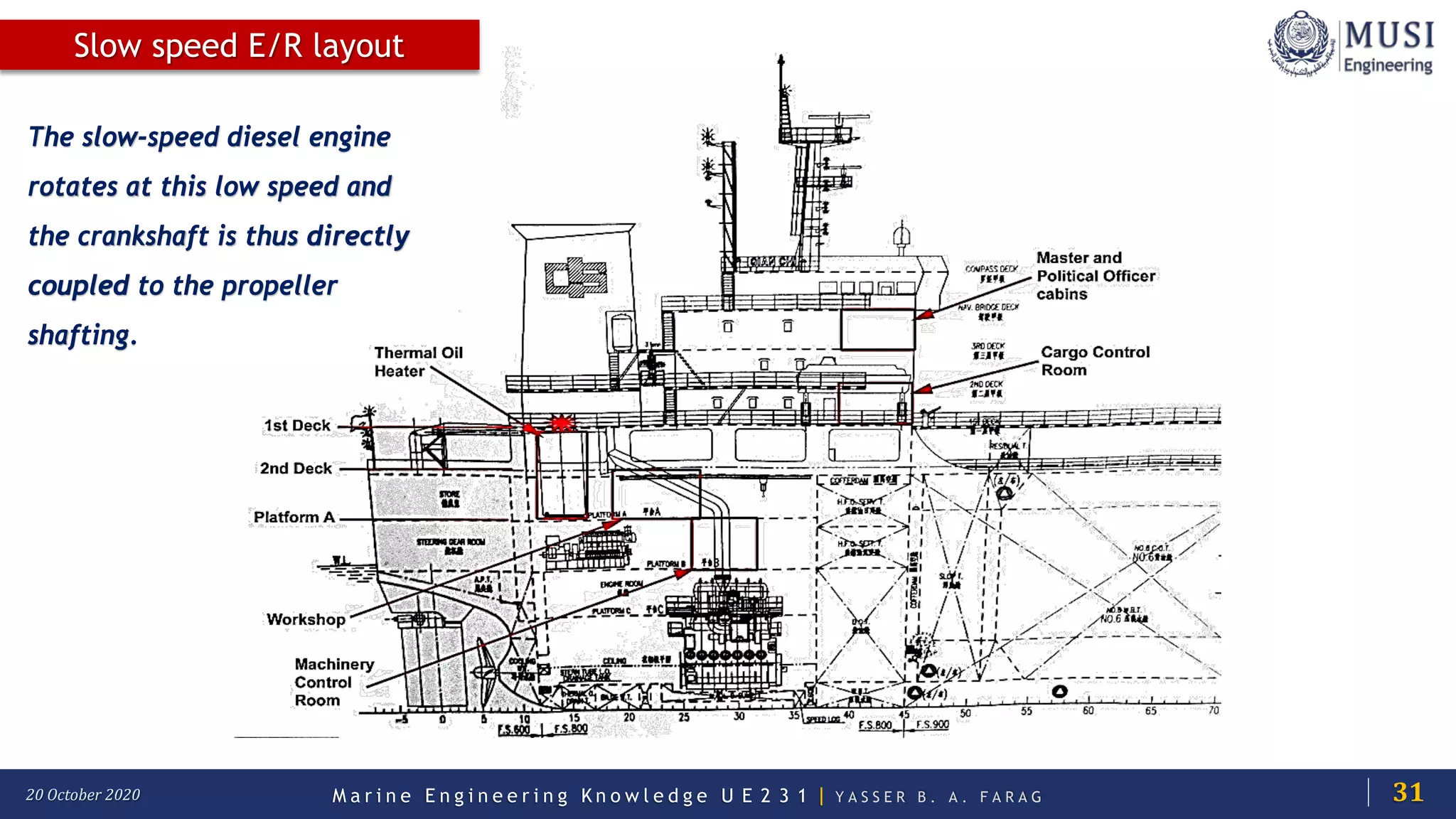

This document provides an overview of the contents of a marine engineering knowledge course taught by Yasser B. A. Farag. The course aims to meet the minimum requirements for knowledge in marine engineering at the management level according to the STCW 78 convention. The course will cover topics related to ship types, machinery systems, and marine engineering knowledge to allow trainees to perform the duties of a second engineer. The course includes references and is divided into sections covering topics such as engines, steering systems, auxiliary machinery, and various ship systems.