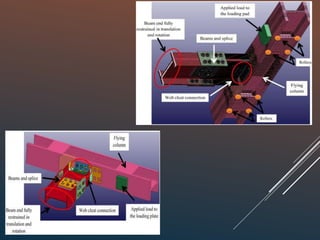

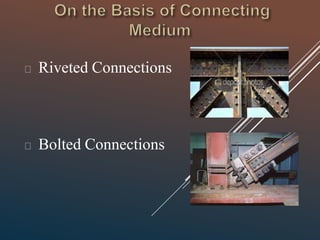

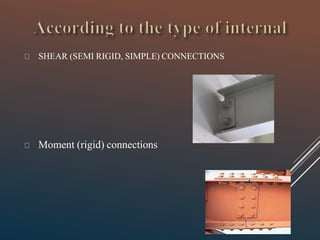

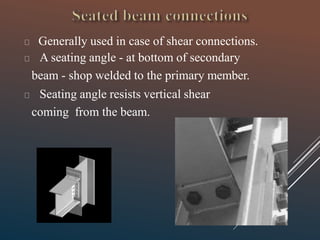

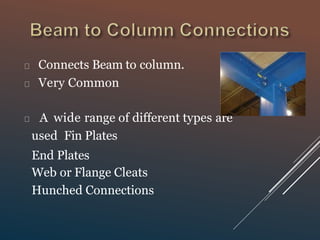

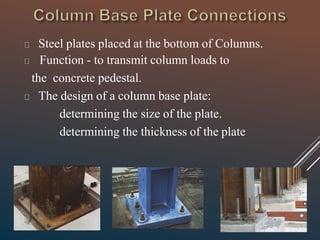

Connections are structural elements used to join members in a steel framework. Common types include bolted connections, welded connections, and bolted-welded combinations. Bolted connections use bolts loaded in tension, shear, or a combination, while welded connections fasten members primarily through welding. Various connection configurations are used for beams to beams, beams to columns, column splices, and attaching columns to foundation plates with anchor bolts. Proper connection design considers the forces and structural role of the connecting members.