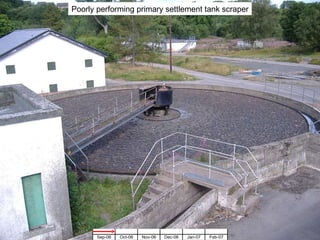

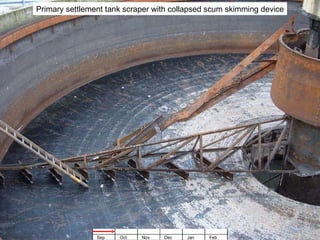

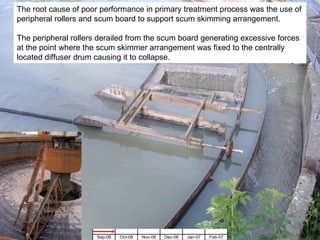

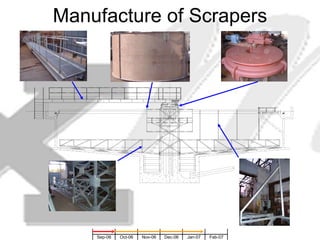

Scottish Water needed to replace two scrapers in a sewage treatment plant near Glasgow. They hired GMJV as the main contractor, who solicited bids for the refurbishment. Xm Services was awarded the contract. The original scrapers were failing due to issues with the scum skimming arrangement. Xm Services designed new scrapers with a robust scum skimming arrangement supported by the rotating scraper arm. They worked closely with suppliers and GMJV during manufacturing, which included factory acceptance tests. Xm Services then decommissioned and removed the old scrapers, and installed and commissioned the new scrapers, completing the project on time.