Abdul Sattar is a production engineer with over 10 years of experience in oil and gas operations including well completions, drilling, acid stimulations, and well interventions. He is currently working at Pakistan Petroleum Limited supervising various production operations such as well completions, coiled tubing jobs, wireline operations, and slickline work. Previously he worked at Oil and Gas Development Company Limited where he was involved in drilling operations, well completions, and drill stem tests. He has strong technical skills and experience in completion equipment, drilling fluids, and production optimization.

![P a g e | 3

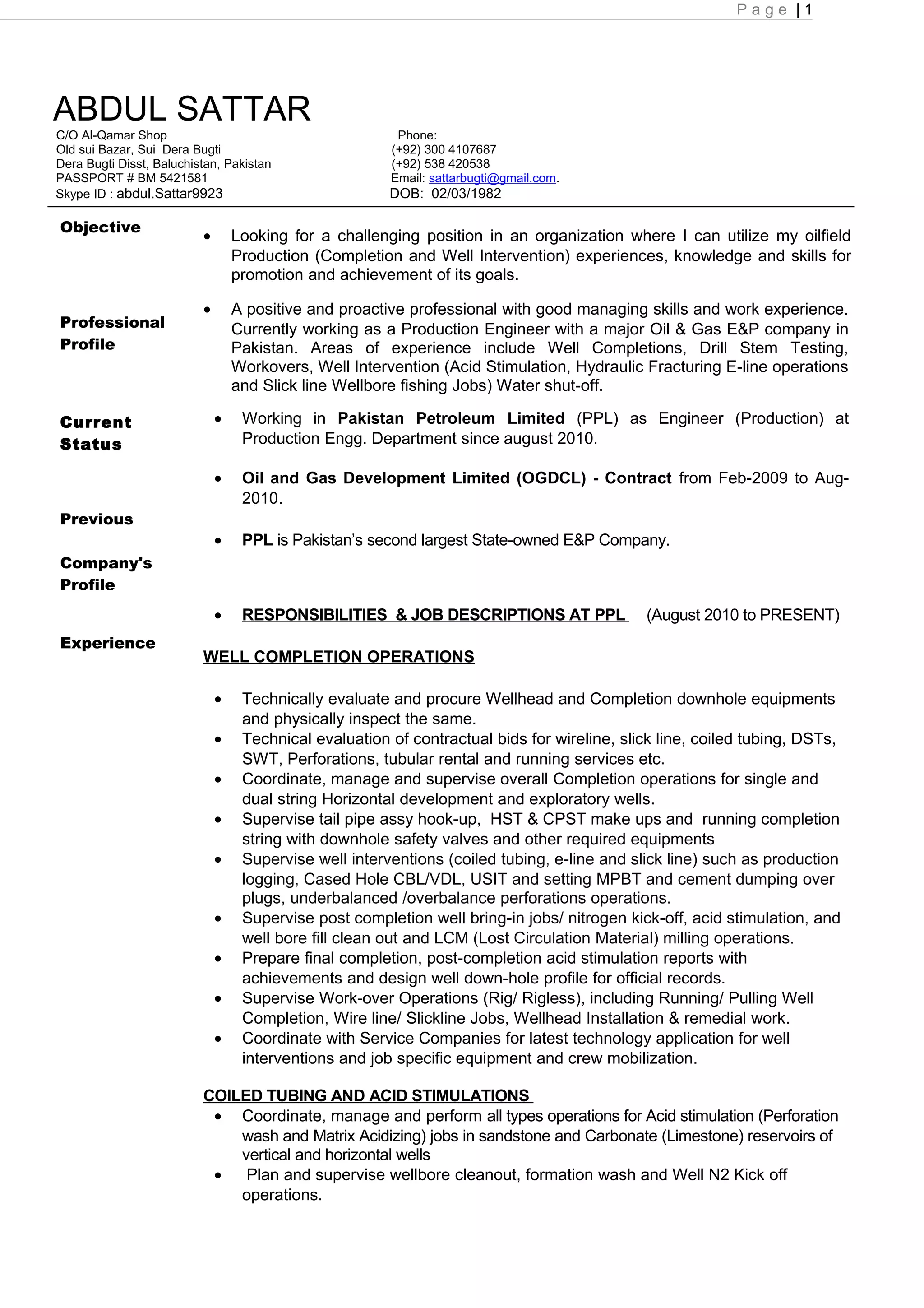

time/ casing running operations.

• Technical coordination of drilling, completions activities to ensure maximum safety,

minimal interruption of drilling, and completion operations.

• Worked in mud system and have vast experience in preparing Water or Oil-based

Drilling fluid, maintaining by means of calculations for reducing mud weight by Oil

or Water, increasing mud weights, site application of retort analysis.

• Rig maintenance activity repairing various mechanical parts like mud pumps

,Swivels, Elevators, BOP, Annular BOP, Kelly Valves and Down Hole BHA parts

like Sleeve Stabilizers, Rotary Reamers, Scrapers, KSW, Kelly Valves, RDCV &

RFCV etc

• Have done several successful Technical Evaluations of drilling Surface & BHA

equipment like Swivels, BOPs Elevators, Kelly Valves, Stabilizers, DC, Drill Pipes

& WHDP, Shock Absorbers RDCV, RFCV, Vacuum Subs etc.

• Supervised over all operation in DST and Cased Hole well Completion for 5 wells

for OGDCL for the project of Uch Gas Phase-II.

• Computer Skills and Software

MS Office & Internet management.

SAP (for MWO,SR, RFQ, FWO and SES).

IHS ( Creating new Index and editing of exiting tool specs)

Academic

Record

• B.S. Petroleum Engineering (March 2009)

Baluchistan University of Engineering & Technology and Management Science, Quetta

Pakistan

Average percentage (1st, division).

Interpersonal

Course

• Good written and verbal communication skills

• Advanced Hydraulic Fracturing by Haward Technology Middle East.

• Leadership skills by Vendor Idea

Languages • Fluent in English, Urdu, Balushi.

Interests

References

• Reading books, playing Football & cricket.

• Mr. Dost Ali [Manager Production Tech. )] Email ID s_dost@ppl.com.pk +923073858443

• Rizwan Bugti [Dy. Chief Engineer (Production Tech)] Email ID r_bugti@ppl.com.pk

+923233939039](https://image.slidesharecdn.com/c831e29b-026d-42c6-94ab-10aca8bcee4a-160701112818/85/A-Sattar-CWI-Engrs-3-320.jpg)