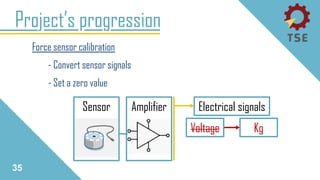

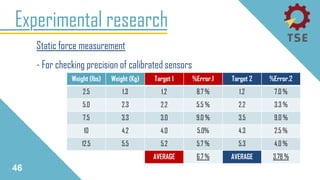

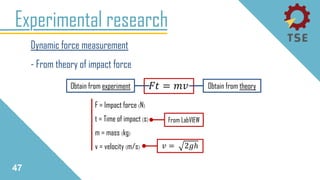

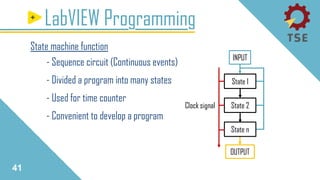

This document describes the design and development of a reaction time and impact force measuring device. The device uses sensors, a data acquisition system, and LabVIEW programming to measure impact force, reaction time, and response time during a punching bag target experiment. Prototypes were developed using various materials and components like load cells, a footswitch, and laser pointer. The device was calibrated and used to collect both static and dynamic force measurements as well as to study force loss through absorption materials. Programming in LabVIEW incorporated state machines to control the experiment sequence and collect/display the measured data.

![9

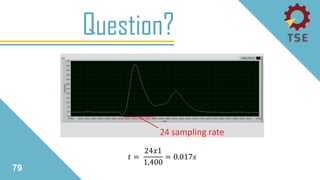

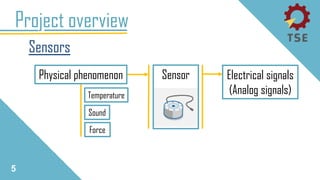

Project overview

Footswitch

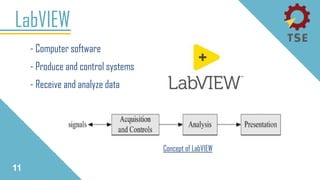

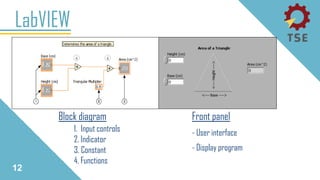

LabVIEW

Sensor

[1]

Laser pointer

Sensor

[2]](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-9-320.jpg)

![Working problem [1]

Conclusion

59

Have delay in work Lack of knowledge

in programming

PROBLEM FROM

Learn from

a professional

SOLUTION

Lack of knowledge

in electrical

instruments](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-59-320.jpg)

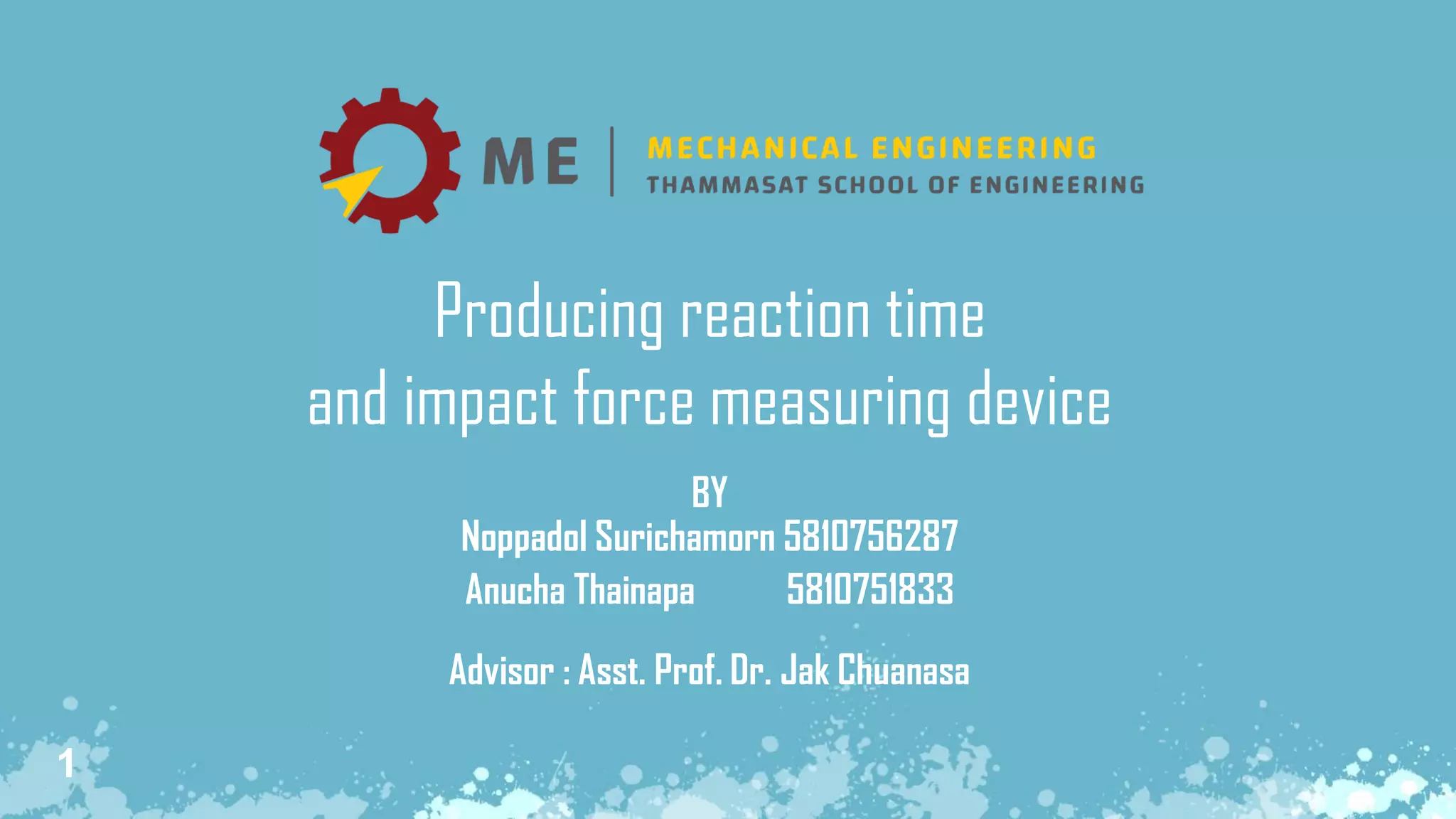

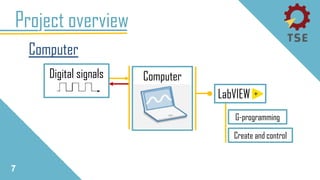

![20

Wiring diagram

ANALOG S.

DIGITAL S.

POWER

CONTROL

Load cell 2

Load cell 1

W.Sensor 1

W.Sensor 2

W.Sensor 3

T.1

T.2

FS.

AMP

[1] [2]

AMP

[3] [4]

AMP

[5]

PS. +24V

Laser 2

Laser 1

+5V

USB-6351 NI

Computer

LabVIEW](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-63-320.jpg)

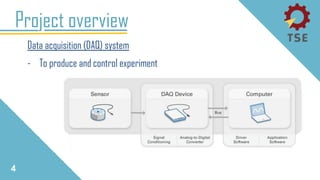

![42

LabVIEW Programming

State .1 [initial]

Clock signals

Wait for going

to next state

Data line](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-67-320.jpg)

![43

LabVIEW Programming

State .2 [ wait_foot_sw_on ]

Footswitch operation

FS. input](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-68-320.jpg)

![44

LabVIEW Programming

State .3 [ delay_5_second ]

Random a delay time](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-69-320.jpg)

![45

LabVIEW Programming

State .4 [ light_on ]

Random laser

LS. output

Count the times](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-70-320.jpg)

![46

LabVIEW Programming

State .5 [ wait_foot_sw_off ]

FS.OFF

Stop reaction T.

Switch state

[target 1] or [target 2]

[7],[8]](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-71-320.jpg)

![47

LabVIEW Programming

State .6 [ wait_target_1_hit ], ( Switching condition =light 1 )

Sensor calibration

Sensor inputs

Stop Response T.

Display the force](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-72-320.jpg)

![48

LabVIEW Programming

State .7 [ wait_target_2_hit ] ,( Switching condition =light 2 )

Sensor calibration

Sensor inputs

Stop Response T.

Display the force](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-73-320.jpg)

![49

LabVIEW Programming

State .8 [ save_data ]

END

Display and

collect data

Collect data as a table](https://image.slidesharecdn.com/finalpresentdone2-190717200933/85/TU-FINAL-THE-MEASURING-DEVICE-1-74-320.jpg)