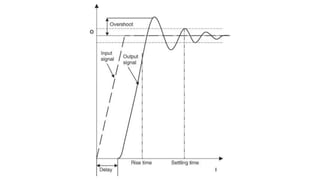

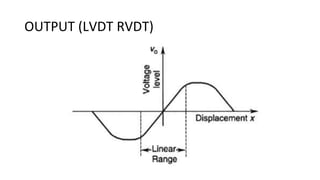

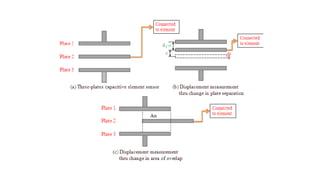

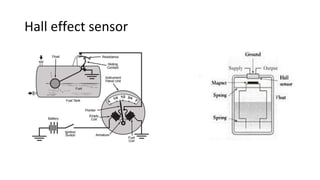

This document discusses various types of sensors used in mechatronic design and control systems. It describes sensors for measuring position, speed, proximity, displacement, force, pressure, temperature and light. Specific sensors covered include LVDT, RVDT, eddy current, capacitive, inductive, Hall effect, strain gauge, optical encoder, photoemitter-detector, piezoelectric and tactile sensors. Applications are provided for different sensors in areas like level measurement, machine tools, assembly lines, hydraulic cylinders and automated inspection. Characteristics of sensors like sensitivity, linearity, range, accuracy and response time are also summarized.